Xinjiang Agricultural Sciences ›› 2025, Vol. 62 ›› Issue (3): 546-555.DOI: 10.6048/j.issn.1001-4330.2025.03.004

• Crop Genetics and Breeding·Cultivation Physiology·Physiology and Biochemistry • Previous Articles Next Articles

XU Shouzhen1( ), MA Qi1, NING Xinzhu1, LI Jilian1, SU Junji2, HAN Huanyong1, WANG Fangyong1, LIN Hai1(

), MA Qi1, NING Xinzhu1, LI Jilian1, SU Junji2, HAN Huanyong1, WANG Fangyong1, LIN Hai1( )

)

Received:2024-09-12

Online:2025-03-20

Published:2025-05-14

Correspondence author:

LIN Hai

Supported by:

徐守振1( ), 马麒1, 宁新柱1, 李吉莲1, 宿俊吉2, 韩焕勇1, 王方永1, 林海1(

), 马麒1, 宁新柱1, 李吉莲1, 宿俊吉2, 韩焕勇1, 王方永1, 林海1( )

)

通讯作者:

林海

作者简介:徐守振(1990-),男,新疆石河子人,助理研究员,研究方向为棉花育种与栽培,(E-mail) xu.shouzhen@foxmail.com

基金资助:CLC Number:

XU Shouzhen, MA Qi, NING Xinzhu, LI Jilian, SU Junji, HAN Huanyong, WANG Fangyong, LIN Hai. Effects of different row spacing and defoliant on cotton defoliation[J]. Xinjiang Agricultural Sciences, 2025, 62(3): 546-555.

徐守振, 马麒, 宁新柱, 李吉莲, 宿俊吉, 韩焕勇, 王方永, 林海. 不同行距和脱叶剂对棉花脱叶效果的影响[J]. 新疆农业科学, 2025, 62(3): 546-555.

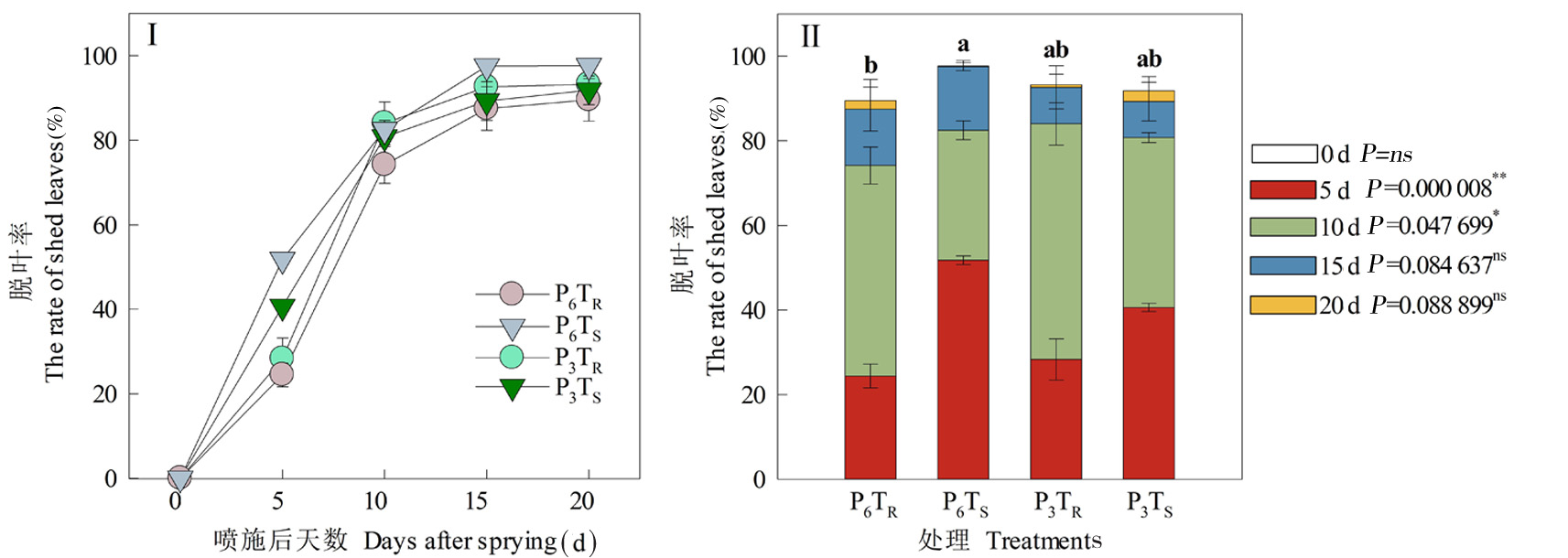

Fig.1 Changes of different treatments on the rate of shed leaves in cotton Notes: P3:Uniform row-spacing configuration, P6:Wide-narrow row-spacing configuration, TR: Ruituolong, TS:Xinthili.The lowercase letter indicated that there were differences among different treatments, * indicated that there were differences among different treatments at 0.05 level, * * indicated that there were differences among different treatments at 0.01 level, and the difference with the same letter was not significant

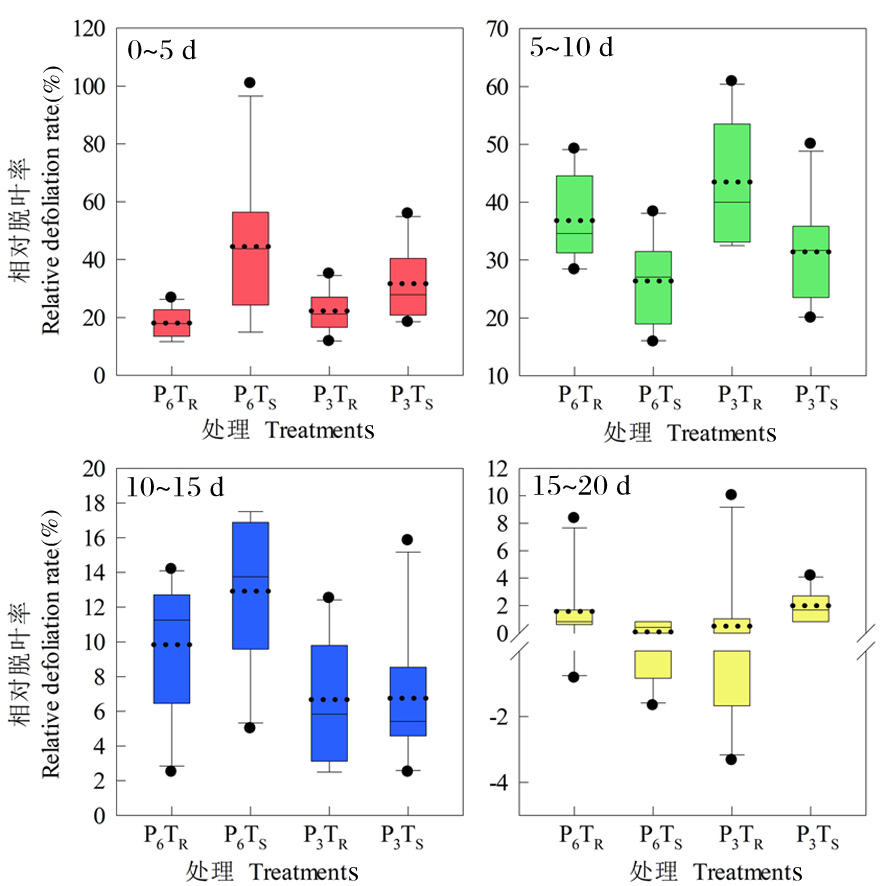

Fig.2 Changs of different treatments on relative defoliation rate of cotton Notes: P3:Uniform row-spacing configuration, P6:Wide-narrow row-spacing configuration.TR: Ruituolong, TS: Xinthili

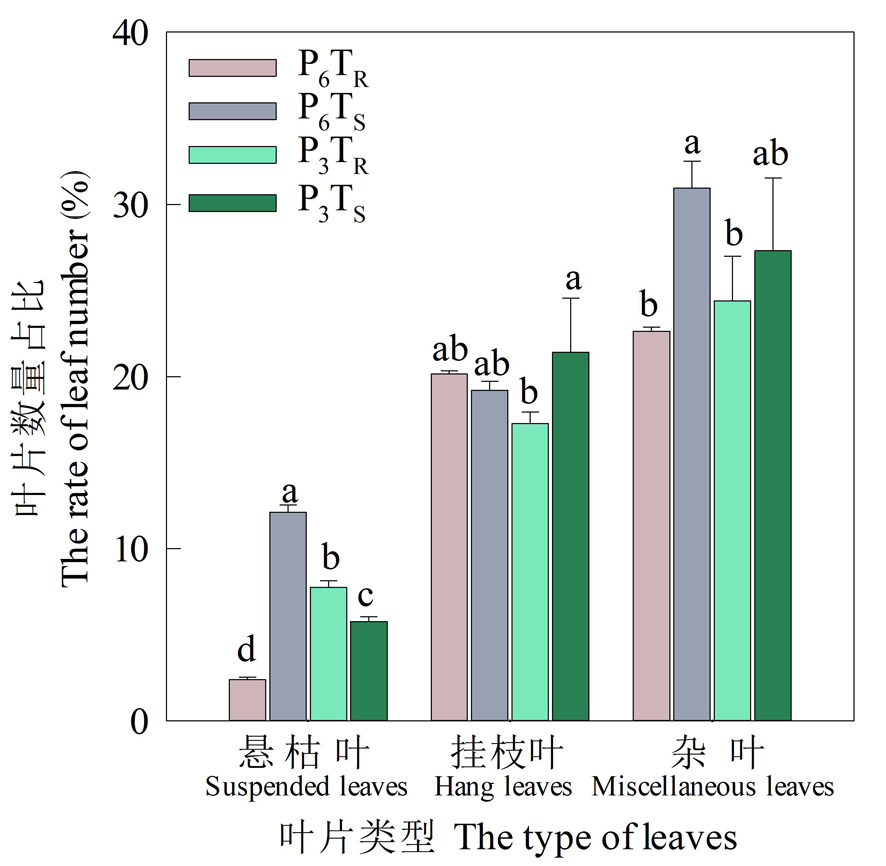

Fig.3 Changes of different treatments on cotton miscellaneous leaves Notes: P3:Uniform row-spacing configuration, P6:Wide-narrow row-spacing configuration.TR: Ruituolong, TS: Xinthili.The lowercase letters indicate that there are differences between different treatments at 0.05 level, and the difference with the same letters is not obvious,the same as below

| 处理 Treatments | 第5果枝 Fifth fruit branch(%) | 第8果枝 Eighth fruit branch(%) | ||||

|---|---|---|---|---|---|---|

| 0~5 d | 5~10 d | 10~15 d | 0~5 d | 5~10 d | 10~15 d | |

| P6TR | 1.18±0.03b | 8.18±0.72b | 4.67±0.56b | 0.48±0.15ab | 0.20±0.04a | 12.22±0.29c |

| P3TR | -0.17±0.12d | 10.70±0.14a | 2.38±0.43c | 0.06±0.05c | -0.46±0.07c | 12.52±0.22c |

| P6TS | 1.50±0.07a | 6.86±0.27c | 5.52±0.31a | 0.62±0.03a | 0.02±0.06b | 12.93±0.20b |

| P3TS | 0.21±0.06c | 10.49±0.64a | 2.48±0.04c | 0.35±0.19b | 0.06±0.04b | 13.51±0.03a |

Tab.1 Difference of dehydration rate of cotton bolls under different treatments

| 处理 Treatments | 第5果枝 Fifth fruit branch(%) | 第8果枝 Eighth fruit branch(%) | ||||

|---|---|---|---|---|---|---|

| 0~5 d | 5~10 d | 10~15 d | 0~5 d | 5~10 d | 10~15 d | |

| P6TR | 1.18±0.03b | 8.18±0.72b | 4.67±0.56b | 0.48±0.15ab | 0.20±0.04a | 12.22±0.29c |

| P3TR | -0.17±0.12d | 10.70±0.14a | 2.38±0.43c | 0.06±0.05c | -0.46±0.07c | 12.52±0.22c |

| P6TS | 1.50±0.07a | 6.86±0.27c | 5.52±0.31a | 0.62±0.03a | 0.02±0.06b | 12.93±0.20b |

| P3TS | 0.21±0.06c | 10.49±0.64a | 2.48±0.04c | 0.35±0.19b | 0.06±0.04b | 13.51±0.03a |

| 处理 Treatments | 部位 Position | 上半部平均长度 Upper half mean length(mm) | 整齐度指数 Fiber uniformity | 断裂比强度 Breaking tenacity (cN/tex) | 马克隆值 Micronaire | 断裂伸长率 Breaking elongation (%) | 反射率 Reflectance degree (%) | 纺纱均匀性指数 Spinning consiitency index |

|---|---|---|---|---|---|---|---|---|

| P3TR | 上部 | 28.83±0.38Ca | 84.40±1.04Aa | 28.53±1.60Aa | 4.87±0.32Aab | 7.63±0.42Ba | 80.07±0.25Ba | 135.33±9.02Aa |

| 中部 | 29.70±0.62Ba | 84.67±1.31Aa | 28.63±0.81Aa | 5.03±0.06Ab | 8.53±0.70ABa | 81.00±0.36Aa | 137.33±7.09Aab | |

| 下部 | 30.70±0.17Aa | 86.70±1.06Aa | 27.93±1.20Aa | 4.67±0.15Aab | 9.53±0.40Aa | 79.57±0.35Ba | 149.67±4.73Aa | |

| P6TR | 上部 | 28.43±0.75Ba | 85.07±0.40Aa | 29.23±0.81Aa | 4.87±0.12Aab | 7.57±0.21Ba | 78.73±1.12Aa | 139.33±3.06Aa |

| 中部 | 28.30±0.61Bb | 85.20±0.36Aa | 27.07±1.02Ba | 5.10±0.10Aab | 8.67±0.68ABa | 79.77±0.35Aa | 131.33±0.58Aab | |

| 下部 | 29.83±0.71Aa | 84.93±1.70Aa | 27.17±0.21Ba | 4.43±0.15Bb | 9.53±0.92Aa | 79.17±1.69Aa | 139.00±8.89Aa | |

| P3TS | 上部 | 26.83±0.95Bb | 84.13±1.03Aa | 26.93±0.90Aa | 5.23±0.06Aa | 7.87±0.75Ba | 78.87±0.35Aa | 121.33±9.61Ba |

| 中部 | 28.43±0.40ABb | 84.00±2.62Aa | 27.30±1.61Aa | 5.33±0.15Aa | 8.17±0.55ABa | 79.83±0.55Aa | 124.67±15.5ABb | |

| 下部 | 29.73±1.05Aa | 86.43±0.67Aa | 28.37±1.15Aa | 4.90±0.17Ba | 9.30±0.36Aa | 80.13±1.00Aa | 145.67±6.51Aa | |

| P6TS | 上部 | 27.67±0.87Aab | 83.40±1.06Ba | 27.13±1.80Aa | 4.67±0.32Ab | 7.53±0.80Ba | 79.67±1.07Aa | 126.00±13.00Ba |

| 中部 | 29.10±0.26Aab | 85.97±0.55Aa | 28.83±2.34Aa | 4.87±0.21Ab | 9.40±0.66Aa | 81.20±0.72Aa | 144.67±6.03Aa | |

| 下部 | 30.37±0.78Ba | 85.43±0.55Aa | 26.77±0.32Aa | 4.63±0.31Aab | 9.17±0.29Aa | 80.07±0.32Aa | 140.00±2.65ABa | |

| 处理Treatments | 0.002** | 0.900ns | 0.510ns | 0.001** | 0.844ns | 0.056 | 0.101ns | |

| 部位Position | 0.000** | 0.010** | 0.685ns | 0.000** | 0.000** | 0.008** | 0.002** | |

| 处理×部位 Treatments×Position | 0.322ns | 0.132ns | 0.119ns | 0.553ns | 0.339ns | 0.504ns | 0.055ns | |

Tab.2 Changes of different treatments on the quality of cotton

| 处理 Treatments | 部位 Position | 上半部平均长度 Upper half mean length(mm) | 整齐度指数 Fiber uniformity | 断裂比强度 Breaking tenacity (cN/tex) | 马克隆值 Micronaire | 断裂伸长率 Breaking elongation (%) | 反射率 Reflectance degree (%) | 纺纱均匀性指数 Spinning consiitency index |

|---|---|---|---|---|---|---|---|---|

| P3TR | 上部 | 28.83±0.38Ca | 84.40±1.04Aa | 28.53±1.60Aa | 4.87±0.32Aab | 7.63±0.42Ba | 80.07±0.25Ba | 135.33±9.02Aa |

| 中部 | 29.70±0.62Ba | 84.67±1.31Aa | 28.63±0.81Aa | 5.03±0.06Ab | 8.53±0.70ABa | 81.00±0.36Aa | 137.33±7.09Aab | |

| 下部 | 30.70±0.17Aa | 86.70±1.06Aa | 27.93±1.20Aa | 4.67±0.15Aab | 9.53±0.40Aa | 79.57±0.35Ba | 149.67±4.73Aa | |

| P6TR | 上部 | 28.43±0.75Ba | 85.07±0.40Aa | 29.23±0.81Aa | 4.87±0.12Aab | 7.57±0.21Ba | 78.73±1.12Aa | 139.33±3.06Aa |

| 中部 | 28.30±0.61Bb | 85.20±0.36Aa | 27.07±1.02Ba | 5.10±0.10Aab | 8.67±0.68ABa | 79.77±0.35Aa | 131.33±0.58Aab | |

| 下部 | 29.83±0.71Aa | 84.93±1.70Aa | 27.17±0.21Ba | 4.43±0.15Bb | 9.53±0.92Aa | 79.17±1.69Aa | 139.00±8.89Aa | |

| P3TS | 上部 | 26.83±0.95Bb | 84.13±1.03Aa | 26.93±0.90Aa | 5.23±0.06Aa | 7.87±0.75Ba | 78.87±0.35Aa | 121.33±9.61Ba |

| 中部 | 28.43±0.40ABb | 84.00±2.62Aa | 27.30±1.61Aa | 5.33±0.15Aa | 8.17±0.55ABa | 79.83±0.55Aa | 124.67±15.5ABb | |

| 下部 | 29.73±1.05Aa | 86.43±0.67Aa | 28.37±1.15Aa | 4.90±0.17Ba | 9.30±0.36Aa | 80.13±1.00Aa | 145.67±6.51Aa | |

| P6TS | 上部 | 27.67±0.87Aab | 83.40±1.06Ba | 27.13±1.80Aa | 4.67±0.32Ab | 7.53±0.80Ba | 79.67±1.07Aa | 126.00±13.00Ba |

| 中部 | 29.10±0.26Aab | 85.97±0.55Aa | 28.83±2.34Aa | 4.87±0.21Ab | 9.40±0.66Aa | 81.20±0.72Aa | 144.67±6.03Aa | |

| 下部 | 30.37±0.78Ba | 85.43±0.55Aa | 26.77±0.32Aa | 4.63±0.31Aab | 9.17±0.29Aa | 80.07±0.32Aa | 140.00±2.65ABa | |

| 处理Treatments | 0.002** | 0.900ns | 0.510ns | 0.001** | 0.844ns | 0.056 | 0.101ns | |

| 部位Position | 0.000** | 0.010** | 0.685ns | 0.000** | 0.000** | 0.008** | 0.002** | |

| 处理×部位 Treatments×Position | 0.322ns | 0.132ns | 0.119ns | 0.553ns | 0.339ns | 0.504ns | 0.055ns | |

| [1] |

熊宗伟, 王雪姣, 顾生浩, 等. 中国棉花纤维品质检验和评价的研究进展[J]. 棉花学报, 2012, 24(5): 451-460.

DOI |

| XIONG Zongwei, WANG Xuejiao, GU Shenghao, et al. Reviews of the cotton fiber quality inspection and evaluation in China[J]. Cotton Science, 2012, 24(5): 451-460. | |

| [2] | 张应波, 田松如, 张翰林, 等. 新疆棉区机采棉推广调研[J]. 中国棉花加工, 2015,(2): 18-20. |

| ZHANG Yingbo, TIAN Songru, ZHANG Hanlin, et al. Investigation on popularization of mechanized cotton picking in Xinjiang cotton region[J]. China Cotton Processing, 2015,(2): 18-20. | |

| [3] | 刘鹏, 戴俊生. 目标价格改革对新疆棉农种植行为意愿及满意度影响分析[J]. 中国市场, 2016,(30): 231-233. |

| LIU Peng, DAI Junsheng. Analysis on the influence of target price reform on cotton farmers' willingness and satisfaction with planting behavior in Xinjiang[J]. China Market, 2016,(30): 231-233. | |

| [4] |

张旺锋, 田景山, 董恒义, 等. 新疆北疆机采棉优质高效综合栽培技术规程[J]. 中国棉花, 2019, 46(6): 37-39.

DOI |

|

ZHANG Wangfeng, TIAN Jingshan, DONG Hengyi, et al. Cultivation technical regulation of fine-quality and high-efficient machine-harvested cotton in northern Xinjiang[J]. China Cotton, 2019, 46(6): 37-39.

DOI |

|

| [5] |

毛树春, 李亚兵, 雷亚平, 等. 转型升级新常态提质增效新措施——用“中高端品质” 棉花引领产业发展, 用“良好棉花” 作为转型提质的新抓手[J]. 中国棉花, 2016, 43(6): 12-13.

DOI |

|

MAO Shuchun, LI Yabing, LEI Yaping, et al. The transformation and upgrading of cotton industry in the new normal economy and the new measure of improving quality and increasing efficiency[J]. China Cotton, 2016, 43(6): 12-13.

DOI |

|

| [6] |

周婷婷, 肖庆刚, 杜睿, 等. 我国棉花脱叶催熟技术研究进展[J]. 棉花学报, 2020, 32(2): 170-184.

DOI |

| ZHOU Tingting, XIAO Qinggang, DU Rui, et al. Research advances on cotton harvest aids in China[J]. Cotton Science, 2020, 32(2): 170-184. | |

| [7] |

吴艳琴, 田景山, 张煦怡, 等. 清理加工工序对新疆机采棉品质的影响[J]. 纺织学报, 2021, 42(11): 24-28.

DOI |

|

WU Yanqin, TIAN Jingshan, ZHANG Xuyi, et al. Effect of cotton cleaning on fiber quality of machine-harvested cotton in Xinjiang region[J]. Journal of Textile Research, 2021, 42(11): 24-28.

DOI |

|

| [8] | 田景山. 新疆机采棉纤维品质影响因素及提质途径研究[D]. 石河子: 石河子大学, 2018. |

| TIAN Jingshan. Study on influencing factors and improving ways of machine-picked cotton fiber quality in Xinjiang[D]. Shihezi: Shihezi University, 2018. | |

| [9] | Krifa M. Fiber length distribution in cotton processing: dominant features and interaction effects[J]. Textile Research Journal, 2006, 76(5): 426-435. |

| [10] | 唐淑荣, 杨伟华, 熊宗伟, 等. 近十几年来我国棉花生产领域纤维品质状况分析[J]. 中国纤检, 2013,(S1): 40-44. |

| TANG Shurong, YANG Weihua, XIONG Zongwei, et al. Analysis on the cotton fiber quality of the production field over the past decade[J]. China Fiber Inspection, 2013,(S1): 40-44. | |

| [11] | Tian J S, Zhang X Y, Zhang W F, et al. Leaf adhesiveness affects damage to fiber strength during seed cotton cleaning of machine-harvested cotton[J]. Industrial Crops and Products, 2017, 107: 211-216. |

| [12] | 雷斌, 张云生, 李忠华, 等. 棉花脱叶剂的田间效果筛选[J]. 新疆农业科学, 2011, 48(12): 2321-2324. |

| LEI Bin, ZHANG Yunsheng, LI Zhonghua, et al. Screening test of different disleave agents for accelerating effect[J]. Xinjiang Agricultural Sciences, 2011, 48(12): 2321-2324. | |

| [13] |

姜伟丽, 马艳, 马小艳, 等. 不同脱叶催熟剂在棉花上的应用效果[J]. 中国棉花, 2013, 40(10): 11-14.

DOI |

|

JIANG Weili, MA Yan, MA Xiaoyan, et al. The application effect of different defoliants and ripeners on cotton[J]. China Cotton, 2013, 40(10): 11-14.

DOI |

|

| [14] | 宋敏, 高文伟, 李贤超, 等. 脱叶剂瑞脱龙对新疆石河子主栽机采棉品种脱叶敏感性和吐絮率的影响分析[J]. 新疆农业大学学报, 2016, 39(1): 40-44. |

| SONG Min, GAO Wenwei, LI Xianchao, et al. Influence of Ruituo dragon defoliant on defoliation sensitivity and boll opening rate of main machine-stripper in shihotze, Xinjiang[J]. Journal of Xinjiang Agricultural University, 2016, 39(1): 40-44. | |

| [15] | 高丽丽, 李淦, 徐新霞, 等. 4种棉花脱叶剂脱叶效果的比较研究[J]. 新疆农业大学学报, 2016, 39(1): 35-39. |

| GAO Lili, LI Gan, XU Xinxia, et al. Comparison of defolianting effects of the defoliants applied for 4 varieties of cotton[J]. Journal of Xinjiang Agricultural University, 2016, 39(1): 35-39. | |

| [16] |

张丽娟, 夏绍南, 李永旗, 等. 新型脱叶剂欣噻利在赣北棉花上的应用效果初报[J]. 中国棉花, 2017, 44(6): 30-32.

DOI |

|

ZHANG Lijuan, XIA Shaonan, LI Yongqi, et al. Preliminary application effect of a new type defoliant, xinsaili, to cotton in northern Jiangxi[J]. China Cotton, 2017, 44(6): 30-32.

DOI |

|

| [17] |

陈兵, 韩焕永, 张国蕾, 等. 4种脱叶催熟剂在棉花上的应用效果研究[J]. 中国棉花, 2017, 44(1): 26-28.

DOI |

|

CHEN Bing, HAN Huanyong, ZHANG Guolei, et al. Effect of four defoliants and ripeners on cotton[J]. China Cotton, 2017, 44(1): 26-28.

DOI |

|

| [18] |

张文, 冯杨, 刘铨义, 等. 脱叶剂不同施用方法对棉花脱叶吐絮及产量和品质的影响[J]. 中国棉花, 2018, 45(5): 26-28.

DOI |

|

ZHANG Wen, FENG Yang, LIU Quanyi, et al. Effects of different application methods of defoliants on defoliation, boll opening, yield and quality of cotton[J]. China Cotton, 2018, 45(5): 26-28.

DOI |

|

| [19] |

胡红岩, 任相亮, 马小艳, 等. 无人机喷施与人工喷施棉花脱叶剂效果对比[J]. 中国棉花, 2018, 45(7): 13-15, 19.

DOI |

|

HU Hongyan, REN Xiangliang, MA Xiaoyan, et al. Comparison of defoliation effects between unmanned air vehicle spraying and artificial spraying in cotton field[J]. China Cotton, 2018, 45(7): 13-15, 19.

DOI |

|

| [20] |

田景山, 张煦怡, 王文敏, 等. 棉花脱叶催熟剂对纤维品质的影响及应用时间的确定[J]. 作物学报, 2020, 46(9): 1388-1397.

DOI |

|

TIAN Jingshan, ZHANG Xuyi, WANG Wenmin, et al. A method of defoliant application based on fiber damage and boll growth period of machine-harvested cotton[J]. Acta Agronomica Sinica, 2020, 46(9): 1388-1397.

DOI |

|

| [21] |

徐守振, 左文庆, 陈民志, 等. 北疆植棉区滴灌量对化学打顶棉花植株农艺性状及产量的影响[J]. 棉花学报, 2017, 29(4): 345-355.

DOI |

| XU Shouzhen, ZUO Wenqing, CHEN Minzhi, et al. Effect of drip irrigation amount on the agronomic traits and yield of cotton grown with a chemical topping in northern Xinjiang, China[J]. Cotton Science, 2017, 29(4): 345-355. | |

| [22] |

周先林, 覃琴, 王龙, 等. 脱叶剂对两种机采模式下棉花脱叶效果及纤维品质的影响[J]. 中国农业科技导报, 2020, 22(11): 144-152.

DOI |

|

ZHOU Xianlin, QIN Qin, WANG Long, et al. Influence of defoliant on defoliation effect and fiber quality of cotton under two kinds of mechanical harvesting modes[J]. Journal of Agricultural Science and Technology, 2020, 22(11): 144-152.

DOI |

|

| [23] | 田晓莉, 段留生, 李召虎, 等. 棉花化学催熟与脱叶的生理基础[J]. 植物生理学通讯, 2004, 40(6): 758-762. |

| TIAN Xiaoli, DUAN Liusheng, LI Zhaohu, et al. Physiological bases of chemical accelerated boll maturation and defoliation in cotton[J]. Plant Physiology Communications, 2004, 40(6): 758-762. | |

| [24] | 孙巍, 杨宝玲, 高振江, 等. 浅析我国棉花机械采收现状及制约因素[J]. 中国农机化学报, 2013, 34(6): 9-13. |

| SUN Wei, YANG Baoling, GAO Zhenjiang, et al. Analysis of mechanical harvest situation and restricting factors of cotton[J]. Journal of Chinese Agricultural Mechanization, 2013, 34(6): 9-13. | |

| [25] | 王聪, 罗宏海, 王明洋, 等. 播种期对不同配置方式杂交棉光合物质生产及产量的影响[J]. 新疆农业科学, 2015, 52(11): 1961-1968. |

| WANG Cong, LUO Honghai, WANG Mingyang, et al. Effects of sowing date on photosynthetic production and yield of hybrid cotton material under different plant models[J]. Xinjiang Agricultural Sciences, 2015, 52(11): 1961-1968. | |

| [26] | 崔岳宁, 高振江, 杨宝玲. 不同行距种植模式下机采棉品质比较分析[J]. 中国农机化学报, 2016, 37(7): 235-240. |

| CUI Yuening, GAO Zhenjiang, YANG Baoling. Quality analysis of different mechanical harvesting cotton planting patterns[J]. Journal of Chinese Agricultural Mechanization, 2016, 37(7): 235-240. | |

| [27] |

李建峰, 王聪, 梁福斌, 等. 新疆机采模式下棉花株行距配置对冠层结构指标及产量的影响[J]. 棉花学报, 2017, 29(2): 157-165.

DOI |

| LI Jianfeng, WANG Cong, LIANG Fubin, et al. Row spacing and planting density affect canopy structure and yield in machine-picked cotton in Xinjiang[J]. Cotton Science, 2017, 29(2): 157-165. | |

| [28] | 李新裕, 陈玉娟, 乔江, 等. 脱叶剂对棉花产量及纤维品质的影响[J]. 中国棉花, 2001, 28(2): 11-13. |

| LI Xinyu, CHEN Yujuan, QIAO Jiang, et al. Effect of defoliant on cotton yield and fiber quality[J]. China Cotton, 2001, 28(2): 11-13. | |

| [29] |

廖宝鹏, 王崧嫚, 杜明伟, 等. 棉花不同部位主茎叶对脱叶剂噻苯隆的响应及机理[J]. 棉花学报, 2020, 32(5): 418-424.

DOI |

| LIAO Baopeng, WANG Songman, DU Mingwei, et al. Responses and underlying mechanisms of different mainstem leaves on cotton to defoliant thidiazuron[J]. Cotton Science, 2020, 32(5): 418-424. | |

| [30] | 何强, 王辉, 郭方剑, 等. 脱叶剂对不同品种棉花脱叶率和吐絮率的影响[J]. 绿洲农业科学与工程, 2021, 7(1): 50-55. |

| [31] | 王彦, 梁艳, 李鲁华. 棉花采净率调查分析[J]. 新疆农垦科技, 2015, 38(11): 12-14. |

| WANG Yan, LIANG Yan, LI Luhua. Investigation and analysis of cotton net picking rate[J]. Xinjiang Farm Research of Science and Technology, 2015, 38(11): 12-14. | |

| [32] | 李健伟, 吴鹏昊, 肖绍伟, 等. 机采种植模式对不同株型棉花脱叶及纤维品质的影响[J]. 干旱地区农业研究, 2019, 37(1): 82-88. |

| LI Jianwei, WU Penghao, XIAO Shaowei, et al. Effects of cotton planting modes with machine picking on defoliation and fiber quality of different plant types[J]. Agricultural Research in the Arid Areas, 2019, 37(1): 82-88. |

| [1] | ZHANG Lingjian, ZHANG Kai, ZHANG Hui, GUO Xiaomeng, CHEN Guoyue, WANG Yiding, JIA Qingyu. Study on the relationship between plant water content and morphological characteristics of top stem and leaf during the whole growth period of cotton [J]. Xinjiang Agricultural Sciences, 2025, 62(3): 531-538. |

| [2] | ZHANG Lian, CHEN Xiangyao, WANG Tangang, MA Xiaomei, CHENG Bin, WANG Gang, DUAN Zhenyu. Effects of high-strength mulch on soil temperature, humidity and cotton growth [J]. Xinjiang Agricultural Sciences, 2025, 62(3): 539-545. |

| [3] | ZHAO Yupeng, CHEN Bolang, WANG Zhiguo, FU Yanbo, BIAN Qingyong. Effects of different carbon source inputs on the characteristics of compacted clay and the growth of cotton seedlings [J]. Xinjiang Agricultural Sciences, 2025, 62(3): 556-571. |

| [4] | WANG Yongpan, MA Jun, LI Chenyu, YAO Mengyao, WANG Zixuan, HUANG Lingzhi, ZHU Haiyan, LIU Wanrong, LI Bo, YANG Yang, GAO Wenwei. Salt tolerance in germination period of cotton seeds based on convolutional neural network and synthetic dataset [J]. Xinjiang Agricultural Sciences, 2025, 62(2): 261-269. |

| [5] | HU Shasha, SHAO Liping, CHEN Lihua, SONG Weiping, ZHAO Hai, ZHANG Xinyu, SUN Jie. Effect of defoliant on boll development and fiber quality of machine-picked cotton [J]. Xinjiang Agricultural Sciences, 2025, 62(2): 270-277. |

| [6] | LU Mingkun, LI Junhong, Nilupaier Yusufujiang, PAN Xipeng, LIU Xiaocheng, ZHANG Zhenggui, PAN Zhanlei, ZHAI Menghua, ZHANG Yaopeng, ZHAO Wenqi, WANG Lihong, WANG Zhanbiao. Effect of silic on fertiliser application on the growth and development of cotton and its yield and quality [J]. Xinjiang Agricultural Sciences, 2025, 62(2): 286-293. |

| [7] | WANG Yiding, ZHANG Kai, ZHANG Lingjian, ZHANG Hui, GUO Xiaomeng, CHEN Guoyue. Effects of drip irrigation on the growth and development, yield formation, and water use efficiency of cotton in Xinjiang [J]. Xinjiang Agricultural Sciences, 2025, 62(2): 294-301. |

| [8] | WANG Xiaoyan, BAI Yungang, CHAI Zhongping, LU Zhenlin, LIU Hongbo, XIAO Jun, Amannisa . Effect of "dry sowing and wet emergence" on cotton growth and yield under the control of winter drip irrigation in off-cropping period [J]. Xinjiang Agricultural Sciences, 2025, 62(2): 302-313. |

| [9] | SUN Caiqin, WU Jia, HUANG Hai, GUO Jiaxin, MIN Wei, GUO Huijuan. Effects of different saline and alkaline stress on the proteome of cotton root system [J]. Xinjiang Agricultural Sciences, 2025, 62(1): 146-160. |

| [10] | LAI Chengxia, YANG Yanlong, WANG Penglong, ZHU Mengyu, YANG Dong, LI Chunping, GE Fengwei, Mayila Yusuyin, YANG Ni, MA Jun. Pathogen colony’s morphological characteristics and pathogenicity identification of defioating cotton Verticillium wilt in some areas in northern Xinjiang [J]. Xinjiang Agricultural Sciences, 2025, 62(1): 174-181. |

| [11] | WANG Wei, ZHANG Renfu, LIU Haiyang, LI Xiaowei, YAO Ju. Occurrence dynamics and spatial distribution pattern of Frankliniella intonsa in cotton fields in Xinjiang [J]. Xinjiang Agricultural Sciences, 2025, 62(1): 202-209. |

| [12] | WEN Fang, LIAO Na, WANG Na, JIN Jing, YAO Yiqiang. Adsorption and immobilization of Cd2+ by cotton straw biochar [J]. Xinjiang Agricultural Sciences, 2025, 62(1): 225-233. |

| [13] | ZHOU Xin, LIU Xuanfeng, JIANG Yuhan, ZHANG Haichun, YANG Yuxin, Yeerbdati Tiemuer, JIANG Yongxin, ZHANG Li. Current situation and development proposal of mechanized recovery and resource utilization of used mulch film in cotton fields in Xinjiang [J]. Xinjiang Agricultural Sciences, 2024, 61(S1): 131-141. |

| [14] | MIAO Hongping, WANG Xiaowei, TIAN Conghua, LI Zhi, ZHANG Yuxin, DAI Junsheng. Evolution characteristics and driving factors of cotton production and distribution in Tarim River basin [J]. Xinjiang Agricultural Sciences, 2024, 61(S1): 217-226. |

| [15] | WANG Junduo, CUI Yujiang, LIANG Yajun, GONG Zhaolong, ZHENG Junyun, LI Xueyuan. Xinjiang cotton production advantageous regional layout scheme [J]. Xinjiang Agricultural Sciences, 2024, 61(S1): 60-69. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||