新疆农业科学 ›› 2024, Vol. 61 ›› Issue (12): 2943-2953.DOI: 10.6048/j.issn.1001-4330.2024.12.009

王佳敏1,2( ), 毛红艳1, 岳丽1, 祖力皮牙·买买提1, 吕玉平1(

), 毛红艳1, 岳丽1, 祖力皮牙·买买提1, 吕玉平1( ), 于明1(

), 于明1( )

)

收稿日期:2024-04-28

出版日期:2024-12-20

发布日期:2025-01-16

通信作者:

吕玉平(1986-),男,内蒙古乌兰察布人,农艺师,研究方向为水稻栽培育种,(E-mail)lvyuping_567@163.com;作者简介:王佳敏(1998 -),女,新疆沙湾人,助理研究员,硕士,研究方向为粮油精深加工,(E-mail)2359796082@qq.com

基金资助:

WANG Jianin1,2( ), MAO Hongyan1, YUE Li1, Zulipiya Maimaiti1, LYU Yuping1(

), MAO Hongyan1, YUE Li1, Zulipiya Maimaiti1, LYU Yuping1( ), YU Ming1(

), YU Ming1( )

)

Received:2024-04-28

Published:2024-12-20

Online:2025-01-16

Supported by:摘要:

【目的】 研究新疆不同品种大米淀粉功能特性差异,为大米加工提供理论依据。【方法】 以新疆种植15种不同的大米品种为材料,采用碱法提取淀粉,测定总淀粉和直链淀粉含量、沉降积、冻融稳定性、透光率、糊化特性、质构特性、溶解度和膨胀度等参数,并对各指标进行显著性、相关性和主成分分析。【结果】 15种大米的总淀粉、直链淀粉含量显著差异(P<0.05),新粳9号直链淀粉含量最高(28.88%);溶解度差异显著(P<0.05),膨胀度在59% ~ 70%。冻融稳定性与冻融循环次数成反比,透光率随静置时间的增加而减小。稻米56号和新粳9号的耐咀嚼性最佳,大米品种与淀粉的直链淀粉含量、糊化特性、质构特性呈显著相关性,新梗9号得分最高。【结论】 不同品种大米理化、功能特性存在差异,其中新粳9号具有良好的加工特性。

中图分类号:

王佳敏, 毛红艳, 岳丽, 祖力皮牙·买买提, 吕玉平, 于明. 不同品种大米淀粉功能特性及主成分分析[J]. 新疆农业科学, 2024, 61(12): 2943-2953.

WANG Jianin, MAO Hongyan, YUE Li, Zulipiya Maimaiti, LYU Yuping, YU Ming. Principal component analysis and comparison of starch functional properties of rice cultivars[J]. Xinjiang Agricultural Sciences, 2024, 61(12): 2943-2953.

| 品种 Varieties | 总淀粉含量 Total starch content (%) | 直链淀粉含量 Straight chain starch content (%) | 支链淀粉含量 Branched chain starch content (%) | 直支比 Ratio of branched starch to straight starch |

|---|---|---|---|---|

| 新粳2号Xinjing 2 | 80.04±0.10ef | 11.58±0.85f | 88.42a | 0.13 |

| 新粳香8号Xinjingxiang 8 | 85.36±0.46cde | 13.52±0.56ef | 86.48a | 0.16 |

| 新粳伊5号Xinjingyi 5 | 90.68±0.87ab | 12.68±0.17ef | 87.32a | 0.15 |

| 稻米56号Daomi 56 | 76.68±0.39f | 20.95±0.80c | 79.05b | 0.26 |

| 新粳香2号Xinjingxiang 2 | 87.49±0.76cd | 19.30±0.68cde | 80.70b | 0.24 |

| 新稻45号Xindao 45 | 91.89±0.72a | 12.43±0.70ef | 87.57a | 0.14 |

| 新粳1号Xinjing 1 | 82.70±0.27e | 22.12±0.13c | 77.88b | 0.28 |

| 粮香8号Liangxiang 8 | 83.85±0.79d | 12.21±0.46f | 87.79a | 0.14 |

| 新粳9号Xinjing 9 | 78.21±0.98f | 28.88±0.56a | 71.12d | 0.41 |

| 新策粳1号Xincejing 1 | 85.25±0.47d | 17.02±0.43d | 82.98ab | 0.21 |

| 新策粳2号Xincejing 2 | 87.67±0.67c | 27.99±0.74a | 72.01d | 0.39 |

| 新稻58号Xindao 58 | 81.63±0.27e | 16.04±0.53e | 83.96ab | 0.19 |

| 新粳8号Xinjing 8 | 82.53±0.63ef | 27.04±0.33b | 72.96c | 0.37 |

| 新粳香1号Xinjingxiang 1 | 89.88±0.31b | 12.67±0.22ef | 87.33a | 0.15 |

| 新粳伊3号Xinjingyi 3 | 88.19±0.28c | 14.27±0.30e | 85.73a | 0.17 |

表1 大米淀粉含量与直链淀粉含量变化

Tab.1 Changes contents of starch and amylose in rice

| 品种 Varieties | 总淀粉含量 Total starch content (%) | 直链淀粉含量 Straight chain starch content (%) | 支链淀粉含量 Branched chain starch content (%) | 直支比 Ratio of branched starch to straight starch |

|---|---|---|---|---|

| 新粳2号Xinjing 2 | 80.04±0.10ef | 11.58±0.85f | 88.42a | 0.13 |

| 新粳香8号Xinjingxiang 8 | 85.36±0.46cde | 13.52±0.56ef | 86.48a | 0.16 |

| 新粳伊5号Xinjingyi 5 | 90.68±0.87ab | 12.68±0.17ef | 87.32a | 0.15 |

| 稻米56号Daomi 56 | 76.68±0.39f | 20.95±0.80c | 79.05b | 0.26 |

| 新粳香2号Xinjingxiang 2 | 87.49±0.76cd | 19.30±0.68cde | 80.70b | 0.24 |

| 新稻45号Xindao 45 | 91.89±0.72a | 12.43±0.70ef | 87.57a | 0.14 |

| 新粳1号Xinjing 1 | 82.70±0.27e | 22.12±0.13c | 77.88b | 0.28 |

| 粮香8号Liangxiang 8 | 83.85±0.79d | 12.21±0.46f | 87.79a | 0.14 |

| 新粳9号Xinjing 9 | 78.21±0.98f | 28.88±0.56a | 71.12d | 0.41 |

| 新策粳1号Xincejing 1 | 85.25±0.47d | 17.02±0.43d | 82.98ab | 0.21 |

| 新策粳2号Xincejing 2 | 87.67±0.67c | 27.99±0.74a | 72.01d | 0.39 |

| 新稻58号Xindao 58 | 81.63±0.27e | 16.04±0.53e | 83.96ab | 0.19 |

| 新粳8号Xinjing 8 | 82.53±0.63ef | 27.04±0.33b | 72.96c | 0.37 |

| 新粳香1号Xinjingxiang 1 | 89.88±0.31b | 12.67±0.22ef | 87.33a | 0.15 |

| 新粳伊3号Xinjingyi 3 | 88.19±0.28c | 14.27±0.30e | 85.73a | 0.17 |

| 品种 Varieties | 峰值粘度 Peak Viscosity | 最低粘度 Tough Viscosity | 崩解值 Breakdown | 最终粘度 Final Viscosity | 回生值 Set Back | 峰值时间 Peak Time(min) | 糊化温度 Pasting Temp(℃) |

|---|---|---|---|---|---|---|---|

| 新粳2号 Xinjing 2 | 5 563.00±46.07 | 1 590.50±10.61 | 3 972.50±56.68 | 3 318.00±52.33 | 1 727.50±62.93 | 4.13±0.00 | 72.43±0.53 |

| 新粳香8号 Xinjingxiang 8 | 6 036.50±98.29 | 1 237.50±75.66 | 4 799.00±22.63 | 2 990.00±26.87 | 1 752.50±102.53 | 4.00±0.00 | 72.88±0.04 |

| 新粳伊5号 Xinjingyi 5 | 5 951.00±33.94 | 1 519.00±83.44 | 4 432.00±117.38 | 2 977.50±31.82 | 1 458.50±51.62 | 4.17±0.05 | 73.28±0.60 |

| 稻米56号 Daomi 56 | 5 485.00±110.31 | 1 582.50±52.03 | 3 902.50±41.72 | 3 253.00±33.75 | 1 670.50±85.78 | 4.10±0.04 | 72.78±0.04 |

| 新粳香2号 Xinjingxiang 2 | 5 425.50±30.41 | 1 555.00±9.90 | 3 870.50±40.31 | 3 358.50±2.12 | 1 803.50±12.02 | 4.10±0.04 | 72.05±0.00 |

| 新稻45号 Xindao 45 | 5 564.00±82.43 | 1 438.00±31.52 | 4 126.00±50.91 | 3 168.00±40.42 | 1 730.00±71.94 | 4.10±0.04 | 72.48±0.60 |

| 新粳1号 Xinjing 1 | 5 533.00±74.95 | 1 441.50±29.40 | 4 091.50±54.45 | 3 126.50±47.79 | 1 685.00±77.19 | 4.10±0.04 | 73.65±1.20 |

| 粮香8号 Liangxiang 8 | 5 643.50±91.43 | 1 363.50±52.03 | 4 280.00±59.40 | 3 270.00±130.11 | 1 906.50±21.92 | 4.13±0.00 | 73.28±.0.06 |

| 新粳9号 Xinjing 9 | 5 418.50±20.51 | 1 554.00±38.18 | 3 864.50±58.69 | 3 421.50±173.24 | 1 867.50±81.42 | 4.13±0.00 | 72.85±0.07 |

| 新策粳1号 Xincejing 1 | 5 442.00±29.70 | 1 496.00±94.75 | 3 946.00±124.45 | 3 186.50±6.36 | 1 690.50±101.12 | 4.24±0.05 | 74.43±0.04 |

| 新策粳2号 Xincejing 2 | 5 602.00±83.44 | 1 314.00±59.40 | 4 288.00±42.84 | 3 122.50±30.41 | 1 808.50±89.80 | 4.07±0.00 | 72.88±0.04 |

| 新稻58号 Xindao 58 | 5 037.00±35.76 | 1 480.50±65.36 | 3 556.50±30.41 | 3 186.50±47.38 | 1 706.00±52.74 | 4.10±0.04 | 74.10±0.57 |

| 新粳8号 Xinjing 8 | 5 611.00±55.15 | 1 575.00±83.44 | 4 036.00±28.28 | 3 287.00±22.63 | 1 712.00±60.81 | 4.13±0.00 | 73.63±0.04 |

| 新粳香1号 Xinjingxiang 1 | 5 674.00±7.07 | 1 638.50±30.41 | 4 035.50±23.33 | 3 522.00±67.88 | 1 883.50±98.29 | 4.17±0.05 | 73.23±0.60 |

| 新粳伊3号 Xinjingyi 3 | 5 271.50±84.15 | 1 646.00±16.97 | 3 625.50±67.18 | 3 291.50±48.79 | 1 645.50±65.76 | 4.17±0.05 | 74.43±0.04 |

表2 大米淀粉粘度特征的变化

Tab.2 Changes viscosity characteristics of rice starch

| 品种 Varieties | 峰值粘度 Peak Viscosity | 最低粘度 Tough Viscosity | 崩解值 Breakdown | 最终粘度 Final Viscosity | 回生值 Set Back | 峰值时间 Peak Time(min) | 糊化温度 Pasting Temp(℃) |

|---|---|---|---|---|---|---|---|

| 新粳2号 Xinjing 2 | 5 563.00±46.07 | 1 590.50±10.61 | 3 972.50±56.68 | 3 318.00±52.33 | 1 727.50±62.93 | 4.13±0.00 | 72.43±0.53 |

| 新粳香8号 Xinjingxiang 8 | 6 036.50±98.29 | 1 237.50±75.66 | 4 799.00±22.63 | 2 990.00±26.87 | 1 752.50±102.53 | 4.00±0.00 | 72.88±0.04 |

| 新粳伊5号 Xinjingyi 5 | 5 951.00±33.94 | 1 519.00±83.44 | 4 432.00±117.38 | 2 977.50±31.82 | 1 458.50±51.62 | 4.17±0.05 | 73.28±0.60 |

| 稻米56号 Daomi 56 | 5 485.00±110.31 | 1 582.50±52.03 | 3 902.50±41.72 | 3 253.00±33.75 | 1 670.50±85.78 | 4.10±0.04 | 72.78±0.04 |

| 新粳香2号 Xinjingxiang 2 | 5 425.50±30.41 | 1 555.00±9.90 | 3 870.50±40.31 | 3 358.50±2.12 | 1 803.50±12.02 | 4.10±0.04 | 72.05±0.00 |

| 新稻45号 Xindao 45 | 5 564.00±82.43 | 1 438.00±31.52 | 4 126.00±50.91 | 3 168.00±40.42 | 1 730.00±71.94 | 4.10±0.04 | 72.48±0.60 |

| 新粳1号 Xinjing 1 | 5 533.00±74.95 | 1 441.50±29.40 | 4 091.50±54.45 | 3 126.50±47.79 | 1 685.00±77.19 | 4.10±0.04 | 73.65±1.20 |

| 粮香8号 Liangxiang 8 | 5 643.50±91.43 | 1 363.50±52.03 | 4 280.00±59.40 | 3 270.00±130.11 | 1 906.50±21.92 | 4.13±0.00 | 73.28±.0.06 |

| 新粳9号 Xinjing 9 | 5 418.50±20.51 | 1 554.00±38.18 | 3 864.50±58.69 | 3 421.50±173.24 | 1 867.50±81.42 | 4.13±0.00 | 72.85±0.07 |

| 新策粳1号 Xincejing 1 | 5 442.00±29.70 | 1 496.00±94.75 | 3 946.00±124.45 | 3 186.50±6.36 | 1 690.50±101.12 | 4.24±0.05 | 74.43±0.04 |

| 新策粳2号 Xincejing 2 | 5 602.00±83.44 | 1 314.00±59.40 | 4 288.00±42.84 | 3 122.50±30.41 | 1 808.50±89.80 | 4.07±0.00 | 72.88±0.04 |

| 新稻58号 Xindao 58 | 5 037.00±35.76 | 1 480.50±65.36 | 3 556.50±30.41 | 3 186.50±47.38 | 1 706.00±52.74 | 4.10±0.04 | 74.10±0.57 |

| 新粳8号 Xinjing 8 | 5 611.00±55.15 | 1 575.00±83.44 | 4 036.00±28.28 | 3 287.00±22.63 | 1 712.00±60.81 | 4.13±0.00 | 73.63±0.04 |

| 新粳香1号 Xinjingxiang 1 | 5 674.00±7.07 | 1 638.50±30.41 | 4 035.50±23.33 | 3 522.00±67.88 | 1 883.50±98.29 | 4.17±0.05 | 73.23±0.60 |

| 新粳伊3号 Xinjingyi 3 | 5 271.50±84.15 | 1 646.00±16.97 | 3 625.50±67.18 | 3 291.50±48.79 | 1 645.50±65.76 | 4.17±0.05 | 74.43±0.04 |

| 品种 Varieties | 硬度 Hardness (g) | 粘附性 Adhesion (g) | 内聚性 Cohesion | 弹性 Elasticity (mm) | 胶粘性 Adhesive (g) | 咀嚼性 Masticatory (mj) |

|---|---|---|---|---|---|---|

| 新粳2号 Xinjing 2 | 25.30±1.10c | 11.44±0.07bc | 0.66±0.00ab | 3.28±0.2b | 16.78±0.9c | 0.55±0.04b |

| 新粳香8号 Xinjingxiang 8 | 15.72±1.23e | 13.53±0.04a | 0.73±0.00a | 3.14±0.14bc | 11.44±0.17d | 0.36±0.06cd |

| 新粳伊5号 Xinjingyi 5 | 23.79±1.14cd | 13.26±0.05ab | 0.72±0.00a | 3.66±0.13a | 17.06±0.23c | 0.63±0.06b |

| 稻米56号 Daomi 56 | 33.81±1.64a | 11.51±0.01bc | 0.71±0.00a | 3.79±0.14a | 24.14±0.26a | 0.92±0.07a |

| 新粳香2号 Xinjingxiang 2 | 26.70±0.97c | 12.28±0.07ab | 0.69±0.00ab | 3.57±0.21ab | 18.47±0.20bc | 0.66±0.04b |

| 新稻45号 Xindao 45 | 24.16±1.15cd | 13.36±0.03ab | 0.71±0.00ab | 3.64±0.30a | 17.14±0.15c | 0.62±0.02b |

| 新粳1号 Xinjing 1 | 24.22±1.19cd | 13.11±0.04ab | 0.72±0.00a | 3.60±0.29a | 17.35±0.10c | 0.63±0.07b |

| 粮香8号 Liangxiang 8 | 18.84±1.16de | 12.84±0.08ab | 0.68±0.00ab | 3.18±0.31b | 12.83±0.34d | 0.41±0.07cd |

| 新粳9号 Xinjing 9 | 36.61±1.13a | 10.16±0.07c | 0.68±0.00ab | 3.41±0.18ab | 24.97±0.25a | 0.85±0.01ab |

| 新策粳1号 Xincejing 1 | 25.30±1.11cd | 11.77±0.02bc | 0.70±0.00ab | 3.41±0.15ab | 17.64±0.11bc | 0.60±0.04b |

| 新策粳2号 Xincejing 2 | 20.67±1.24d | 12.05±0.02b | 0.68±0.00ab | 3.08±0.14bc | 14.03±0.09d | 0.43±0.04c |

| 新稻58号 Xindao 58 | 29.93±1.10b | 10.73±0.04c | 0.65±0.00b | 3.33±0.07b | 19.55±0.19b | 0.65±0.06b |

| 新粳8号 Xinjing 8 | 28.53±1.11bc | 10.88±0.07bc | 0.71±0.00ab | 3.36±0.06ab | 20.20±0.25b | 0.68±0.02b |

| 新粳香1号 Xinjingxiang 1 | 27.99±1.17bc | 11.18±0.04bc | 0.67±0.00ab | 3.32±0.30b | 18.64±0.22bc | 0.62±0.03b |

| 新粳伊3号 Xinjingyi 3 | 18.20±1.11de | 11.27±0.02bc | 0.65±0.00b | 2.71±0.29c | 11.89±0.37d | 0.32±0.01d |

表3 淀粉凝胶质构特性的变化

Tab.3 Changes texture properties of starch gels

| 品种 Varieties | 硬度 Hardness (g) | 粘附性 Adhesion (g) | 内聚性 Cohesion | 弹性 Elasticity (mm) | 胶粘性 Adhesive (g) | 咀嚼性 Masticatory (mj) |

|---|---|---|---|---|---|---|

| 新粳2号 Xinjing 2 | 25.30±1.10c | 11.44±0.07bc | 0.66±0.00ab | 3.28±0.2b | 16.78±0.9c | 0.55±0.04b |

| 新粳香8号 Xinjingxiang 8 | 15.72±1.23e | 13.53±0.04a | 0.73±0.00a | 3.14±0.14bc | 11.44±0.17d | 0.36±0.06cd |

| 新粳伊5号 Xinjingyi 5 | 23.79±1.14cd | 13.26±0.05ab | 0.72±0.00a | 3.66±0.13a | 17.06±0.23c | 0.63±0.06b |

| 稻米56号 Daomi 56 | 33.81±1.64a | 11.51±0.01bc | 0.71±0.00a | 3.79±0.14a | 24.14±0.26a | 0.92±0.07a |

| 新粳香2号 Xinjingxiang 2 | 26.70±0.97c | 12.28±0.07ab | 0.69±0.00ab | 3.57±0.21ab | 18.47±0.20bc | 0.66±0.04b |

| 新稻45号 Xindao 45 | 24.16±1.15cd | 13.36±0.03ab | 0.71±0.00ab | 3.64±0.30a | 17.14±0.15c | 0.62±0.02b |

| 新粳1号 Xinjing 1 | 24.22±1.19cd | 13.11±0.04ab | 0.72±0.00a | 3.60±0.29a | 17.35±0.10c | 0.63±0.07b |

| 粮香8号 Liangxiang 8 | 18.84±1.16de | 12.84±0.08ab | 0.68±0.00ab | 3.18±0.31b | 12.83±0.34d | 0.41±0.07cd |

| 新粳9号 Xinjing 9 | 36.61±1.13a | 10.16±0.07c | 0.68±0.00ab | 3.41±0.18ab | 24.97±0.25a | 0.85±0.01ab |

| 新策粳1号 Xincejing 1 | 25.30±1.11cd | 11.77±0.02bc | 0.70±0.00ab | 3.41±0.15ab | 17.64±0.11bc | 0.60±0.04b |

| 新策粳2号 Xincejing 2 | 20.67±1.24d | 12.05±0.02b | 0.68±0.00ab | 3.08±0.14bc | 14.03±0.09d | 0.43±0.04c |

| 新稻58号 Xindao 58 | 29.93±1.10b | 10.73±0.04c | 0.65±0.00b | 3.33±0.07b | 19.55±0.19b | 0.65±0.06b |

| 新粳8号 Xinjing 8 | 28.53±1.11bc | 10.88±0.07bc | 0.71±0.00ab | 3.36±0.06ab | 20.20±0.25b | 0.68±0.02b |

| 新粳香1号 Xinjingxiang 1 | 27.99±1.17bc | 11.18±0.04bc | 0.67±0.00ab | 3.32±0.30b | 18.64±0.22bc | 0.62±0.03b |

| 新粳伊3号 Xinjingyi 3 | 18.20±1.11de | 11.27±0.02bc | 0.65±0.00b | 2.71±0.29c | 11.89±0.37d | 0.32±0.01d |

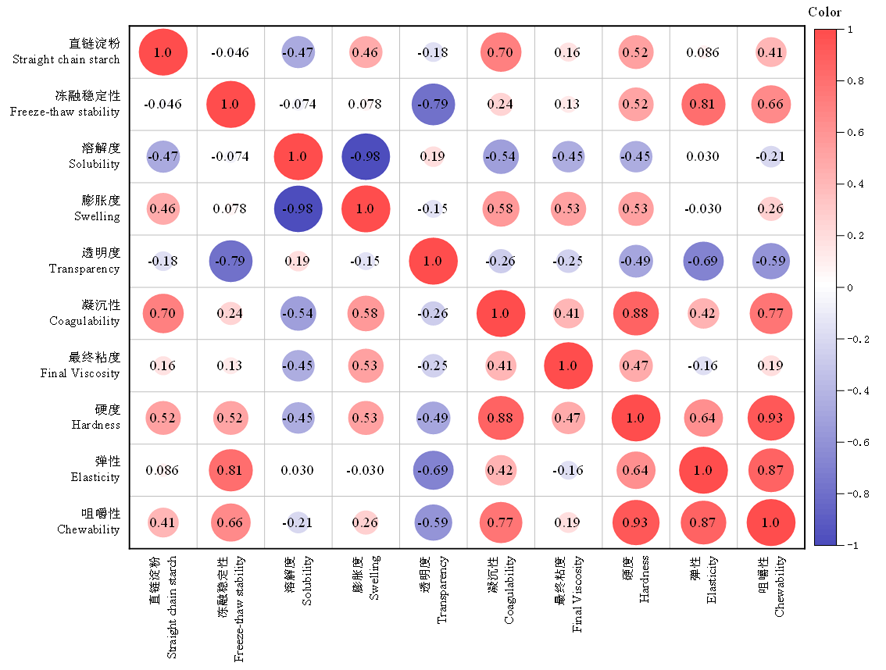

图 5 淀粉理化特性相关性 注:红色、蓝色分别表示正相关与负相关

Fig.5 Correlation analysis of starch physicochemical properties Notes:Red and blue represent positive and negative correlations,respectively

| 品种 Varieties | FAC1 | FAC2 | FAC3 | FAC4 | FAC5 | 综合得分 (T分值转换) Composite Score (T-score conversion) |

|---|---|---|---|---|---|---|

| 新粳2号Xinjing 2 | 0.309 30 | 0.505 29 | -1.148 86 | 0.663 53 | 1.409 39 | 62.35 |

| 新粳香8号Xinjingxiang 8 | -0.748 78 | -1.866 67 | -0.751 85 | -1.034 78 | 0.017 24 | 51.31 |

| 新粳伊5号Xinjingyi 5 | 0.777 49 | 0.739 10 | -1.033 80 | -1.850 59 | 0.368 50 | 61.59 |

| 稻米56号Daomi 56 | 1.490 15 | -2.291 35 | 1.085 89 | 0.043 94 | 1.243 17 | 64.02 |

| 新粳香2号Xinjingxiang 2 | 0.455 56 | 0.156 61 | 0.318 49 | 0.686 78 | -1.973 33 | 61.72 |

| 新稻45号Xindao 45 | 0.750 12 | -0.224 87 | -1.018 50 | -0.466 86 | -1.132 59 | 59.81 |

| 新粳1号Xinjing 1 | 0.705 87 | 1.291 20 | 0.423 20 | -1.027 19 | -0.380 93 | 64.64 |

| 粮香8号Liangxiang 8 | -1.030 26 | -0.128 01 | -0.750 25 | 0.203 19 | 0.717 63 | 55.33 |

| 新粳9号Xinjing 9 | 0.737 16 | 0.794 39 | 1.290 24 | 1.112 84 | 1.194 15 | 68.31 |

| 新策粳1号Xincejing 1 | -0.165 50 | -0.226 34 | 0.124 40 | -0.333 93 | -0.920 94 | 58.03 |

| 新策粳2号Xincejing 2 | -1.329 91 | -0.373 50 | 1.083 21 | -0.616 77 | -0.431 63 | 54.53 |

| 新稻58号Xindao 58 | 0.190 12 | 1.259 59 | -0.014 38 | -0.344 13 | 0.784 15 | 63.47 |

| 新粳8号Xinjing 8 | -0.343 08 | 0.329 23 | 1.848 12 | 0.109 31 | -0.611 05 | 61.49 |

| 新粳香1号Xinjingxiang 1 | 0.528 92 | -0.288 60 | -1.301 13 | 2.246 20 | -0.851 17 | 61.27 |

| 新粳伊3号Xinjingyi 3 | -2.327 16 | 0.323 93 | -0.154 80 | 0.608 45 | 0.567 42 | 52.13 |

表5 大米淀粉主成分

Tab.5 Principal component analysis of rice starch

| 品种 Varieties | FAC1 | FAC2 | FAC3 | FAC4 | FAC5 | 综合得分 (T分值转换) Composite Score (T-score conversion) |

|---|---|---|---|---|---|---|

| 新粳2号Xinjing 2 | 0.309 30 | 0.505 29 | -1.148 86 | 0.663 53 | 1.409 39 | 62.35 |

| 新粳香8号Xinjingxiang 8 | -0.748 78 | -1.866 67 | -0.751 85 | -1.034 78 | 0.017 24 | 51.31 |

| 新粳伊5号Xinjingyi 5 | 0.777 49 | 0.739 10 | -1.033 80 | -1.850 59 | 0.368 50 | 61.59 |

| 稻米56号Daomi 56 | 1.490 15 | -2.291 35 | 1.085 89 | 0.043 94 | 1.243 17 | 64.02 |

| 新粳香2号Xinjingxiang 2 | 0.455 56 | 0.156 61 | 0.318 49 | 0.686 78 | -1.973 33 | 61.72 |

| 新稻45号Xindao 45 | 0.750 12 | -0.224 87 | -1.018 50 | -0.466 86 | -1.132 59 | 59.81 |

| 新粳1号Xinjing 1 | 0.705 87 | 1.291 20 | 0.423 20 | -1.027 19 | -0.380 93 | 64.64 |

| 粮香8号Liangxiang 8 | -1.030 26 | -0.128 01 | -0.750 25 | 0.203 19 | 0.717 63 | 55.33 |

| 新粳9号Xinjing 9 | 0.737 16 | 0.794 39 | 1.290 24 | 1.112 84 | 1.194 15 | 68.31 |

| 新策粳1号Xincejing 1 | -0.165 50 | -0.226 34 | 0.124 40 | -0.333 93 | -0.920 94 | 58.03 |

| 新策粳2号Xincejing 2 | -1.329 91 | -0.373 50 | 1.083 21 | -0.616 77 | -0.431 63 | 54.53 |

| 新稻58号Xindao 58 | 0.190 12 | 1.259 59 | -0.014 38 | -0.344 13 | 0.784 15 | 63.47 |

| 新粳8号Xinjing 8 | -0.343 08 | 0.329 23 | 1.848 12 | 0.109 31 | -0.611 05 | 61.49 |

| 新粳香1号Xinjingxiang 1 | 0.528 92 | -0.288 60 | -1.301 13 | 2.246 20 | -0.851 17 | 61.27 |

| 新粳伊3号Xinjingyi 3 | -2.327 16 | 0.323 93 | -0.154 80 | 0.608 45 | 0.567 42 | 52.13 |

| [1] | Li C, Yu W W, Gilbert R G. The effects of starch molecular fine structure on thermal and digestion properties of rice starch[J]. Foods, 2022, 11(24): 4012. |

| [2] | 顾晓振, 米铁柱, 刘佳音, 等. 中国杂交粳稻育种研究进展[J]. 杂交水稻, 2021, 36(4): 1-5. |

| GU Xiaozhen, MI Tiezhu, LIU Jiayin, et al. Research advances in breeding of Japonica hybrid rice in China[J]. Hybrid Rice, 2021, 36(4): 1-5. | |

| [3] |

布哈丽且木·阿不力孜, 袁杰, 朱小霞, 等. 新疆稻区优质丰产水稻品种筛选与评价[J]. 新疆农业科学, 2020, 57(11): 2108-2117.

DOI |

|

Buhaliqiemu Abulizi, YUAN Jie, ZHU Xiaoxia, et al. Screening and evaluation of high-quality and high-yield rice varieties in Xinjiang rice zone[J]. Xinjiang Agricultural Sciences, 2020, 57(11): 2108-2117.

DOI |

|

| [4] |

占小登, 王凯, 曹立勇. 近年我国水稻遗传育种研究进展与展望[J]. 中国稻米, 2023, 29(6): 1-4.

DOI |

|

ZHAN Xiaodeng, WANG Kai, CAO Liyong. Advance and prospect of rice genetics and breeding research in 2020—2022 in China[J]. China Rice, 2023, 29(6): 1-4.

DOI |

|

| [5] | Kim J Y, Lee Y K, Chang Y H. Structure and digestibility properties of resistant rice starch cross-linked with citric acid[J]. International Journal of Food Properties, 2017: 1-12. |

| [6] | Tang A X, Li M, Wang R B, et al. Manipulating raw noodle crystallinity to control the hardness of cooked noodle[J]. LWT, 2019, 109: 305-312. |

| [7] | Sangwongchai W, Tananuwong K, Krusong K, et al. Starch chemical composition and molecular structure in relation to physicochemical characteristics and resistant starch content of four Thai commercial rice cultivars differing in pasting properties[J]. Polymers, 2023, 15(3): 574. |

| [8] |

Syafutri M I, Pratama F, Syaiful F, et al. Effects of varieties and cooking methods on physical and chemical characteristics of cooked rice[J]. Rice Science, 2016, 23(5): 282-286.

DOI |

| [9] | 唐雅璐, 全珂, 刘艳兰, 等. 大米淀粉三种提取方法的对比研究[J]. 粮食与食品工业, 2020, 27(4): 32-38, 45. |

| TANG Yalu, QUAN Ke, LIU Yanlan, et al. Compared among three extraction methods on rice starch[J]. Cereal & Food Industry, 2020, 27(4): 32-38, 45. | |

| [10] | 李真, 安阳, 艾志录, 等. 不同类型变性淀粉的理化特性比较[J]. 中国食品学报, 2019, 19(4): 280-286. |

| LI Zhen, AN Yang, AI Zhilu, et al. Studies on physico-chemical properties of different types modified starches[J]. Journal of Chinese Institute of Food Science and Technology, 2019, 19(4): 280-286. | |

| [11] | Cheng J Y, Lei S J, Gao L, et al. Effects of jet milling on the physicochemical properties of buckwheat flour and the quality characteristics of extruded whole buckwheat noodles[J]. Foods, 2022, 11(18): 2722. |

| [12] | 张晓萌, 陈金凤, 李建刚, 等. 超高压处理对“和尚头”小麦淀粉结构和特性的影响[J/OL]. 食品与发酵工业: 1-9. |

| ZHANG Xiaomeng, CHEN Jinfeng, LI Jiangang, et al. Effects of ultrahigh-pressure treatment on the structure and properties of wheat starch from "Monk's Head"[J/OL]. Food and Fermentation Industry: 1-9. | |

| [13] | Liu X X, Liu H M, Li J, et al. Effects of various oil extraction methods on the structural and functional properties of starches isolated from tigernut (Cyperus esculentus) Tuber meals[J]. Food Hydrocolloids, 2019, 95: 262-272. |

| [14] | 潘俊娴, 吕杨俊, 蒋玉兰, 等. 茶多酚对大米淀粉理化特性的影响[J]. 中国茶叶加工, 2023, (3): 45-51. |

| PAN Junxian, LYU Yangjun, JIANG Yulan, et al. Effect of tea polyphenols on the physicochemical properties of rice starch[J]. China Tea Processing, 2023, (3): 45-51. | |

| [15] | Yang J Y, Reddy C K, Fan Z L, et al. Physicochemical and structural properties of starches from non-traditional sources in China[J]. Food Science and Human Wellness, 2023, 12(2): 416-423. |

| [16] | Lindeboom N, Chang P R, Tyler R T. Analytical, biochemical and physicochemical aspects of starch granule size, with emphasis on small granule starches: a review[J]. Starch - Strke, 2004, 56(3/4): 89-99. |

| [17] | Wei P, Fang F, Liu G M, et al. Effects of composition, thermal, and theological properties of rice raw material on rice noodle quality[J]. Frontiers in Nutrition, 2022, 9: 1003657. |

| [18] | Chan C H, Wu R G, Shao Y Y. The effects of ultrasonic treatment on physicochemical properties and in vitro digestibility of semigelatinized high amylose maize starch[J]. Food Hydrocolloids, 2021, 119: 106831. |

| [19] | Ohtsubo K, Brites C M, Rosell C M. Editorial for the special issue, “quality assay, processing and bio-function of rice products”[J]. Foods, 2022, 11(12): 1755. |

| [20] |

Li H Y, Gilbert R G. Starch molecular structure: The basis for an improved understanding of cooked rice texture[J]. Carbohydrate Polymers, 2018, 195: 9-17.

DOI PMID |

| [21] |

Meera K, Smita M, Haripriya S, et al. Varietal influence on antioxidant properties and glycemic index of pigmented and non-pigmented rice[J]. Journal of Cereal Science, 2019, 87: 202-208.

DOI |

| [22] | Ngo T V, Kunyanee K, Luangsakul N. Insights into recent updates on factors and technologies that modulate the glycemic index of rice and its products[J]. Foods, 2023, 12(19): 3659. |

| [23] | Chen B R, Wang C Y, Wang P, et al. Genome-wide association study for starch content and constitution in Sorghum (Sorghum bicolor (L.) Moench)[J]. Journal of Integrative Agriculture, 2019, 18(11): 2446-2456. |

| [24] | 阚卓锐. 杂粮复配粉中淀粉直/支比对挤压面条品质的影响[D]. 天津: 天津科技大学, 2022. |

| KAN Zhuorui. Effect of starch straight/branch ratio in mixed grain compound flour on the quality of extruded noodles[D]. Tianjin: Tianjin University of Science & Technology, 2022. | |

| [25] | 夏凡, 董月, 朱蕾, 等. 大米理化性质与其食用品质相关性研究[J]. 粮食科技与经济, 2018, 43(5): 100-107. |

| XIA Fan, DONG Yue, ZHU Lei, et al. Study on the relationship between physicochemical properties and edible quality of rice[J]. Grain Science and Technology and Economy, 2018, 43(5): 100-107. | |

| [26] | Cai Q L, Li X P, Ding X X, et al. Effects of quercetin and Ca(OH)2 addition on gelatinization and retrogradation properties of Tartary buckwheat starch[J]. LWT, 2023, 178: 114488. |

| [27] | 岳书杭. 醋酸酯大米淀粉的合成、性质及应用研究[D]. 湘潭: 湘潭大学, 2019. |

| YUE Shuhang. Synthesis, Properties and Application of Rice Starch with Acetate[D]. Xiangtan: Xiangtan University, 2019. | |

| [28] | Batanony N, MahaHamdyAli M, TantawyHassan H. Diversity of non-rhizobial bacteria from nodules of Melilotus indicus L. and their plant growth promotion ability[J]. The Egyptian Journal of Experimental Biology (Botany), 2018, 14(2): 253. |

| [29] | 宋永, 贾璐泽, 张一婷, 等. 金冠豆角籽粒淀粉组成及性质研究[J/OL]. 食品工业科技, 1-15. |

| SONG Yong, JIA Luze, ZHANG Yiting, et al. Study on the composition and properties of starch in the seeds of golden corns[J/OL]. Food Industry Science and Technology, 1-15. | |

| [30] | 潘俊娴, 吕杨俊, 蒋玉兰, 等. 龙游黄茶茶粉对大米淀粉理化特性的影响[J]. 中国茶叶加工, 2023,(3): 52-56. |

| PAN Junxian, LYU Yangjun, JIANG Yulan, et al. Effect of tea powder from Longyou yellow tea on the physicochemical properties of rice starch[J]. China Tea Processing, 2023,(3): 52-56. | |

| [31] | Shen S D, Chi C D, Zhang Y P, et al. New insights into how starch structure synergistically affects the starch digestibility, texture, and flavor quality of rice noodles[J]. International Journal of Biological Macromolecules, 2021, 184: 731-738. |

| [32] | Osei Tutu C, Amissah J G N, Amissah J N, et al. Physicochemical and microstructural characteristics of Frafra potato (Solenostemon rotundifolius) starch[J]. International Journal of Food Properties, 2023, 26(1): 1624-1635. |

| [33] | Yan S X, Li Z, Wang B, et al. Correlation analysis on physicochemical and structural properties of Sorghum starch[J]. Frontiers in Nutrition, 2023, 9: 1101868. |

| [34] |

Yamaguchi Y, Okawa Y, Ninomiya K, et al. Evaluation and suppression of retrogradation of gelatinized rice starch[J]. Journal of Nutritional Science and Vitaminology, 2019, 65(Supplement): 134-138.

DOI PMID |

| [35] | 何丹, 李粤, 邬应龙. 蚕豆和高直链玉米淀粉对马铃薯粉条品质的影响[J]. 中国调味品, 2023, 48(10): 66-72. |

| HE Dan, LI Yue, WU Yinglong. Effects of faba bean starch and high amylose corn starch on quality of potato vermicelli[J]. China Condiment, 2023, 48(10): 66-72. | |

| [36] | Chen H, Wang T, Deng F, et al. Changes in chemical composition and starch structure in rice noodle cultivar influence Rapid Visco analysis and texture analysis profiles under shading[J]. Food Chemistry: X, 2022, 14: 100360. |

| [37] |

Farooq A M, Li C, Chen S Q, et al. Particle size affects structural and in vitro digestion properties of cooked rice flours[J]. International Journal of Biological Macromolecules, 2018, 118: 160-167.

DOI PMID |

| [38] | Gao F, Li X Q, Li X, et al. Physicochemical properties and correlation analysis of retrograded starch from different varieties of Sorghum[J]. International Journal of Food Science & Technology, 2022, 57(10): 6678-6689. |

| [39] | 柯福来, 张旷野, 朱凯, 等. 不同高粱品系籽粒淀粉的构成与糊化特性相关性分析[J/OL]. 山西农业大学学报(自然科学版), 1-7. |

| KE Fulai, ZHANG Kuangye, ZHU Kai, et al. Correlation between grain starch composition and pasting characteristics of different sorghum lines[J/OL]. Journal of Shanxi Agricultural University (Natural Science Edition), 1-7. | |

| [40] | 盛周杨, 邹波, 吴继军, 等. 木薯淀粉及改性淀粉结构特性及其与粉圆品质的关系[J/OL]. 广东农业科学, 1-10. |

| SHENG Zhouyang, ZOU Bo, WU Jijun, et al. Structural properties of cassava starch and modified starch and their relationship with the quality of vermicelli[J/OL]. Guangdong Agricultural Science, 1-10. |

| [1] | 曾婉盈, 耿洪伟, 程宇坤, 李思忠, 钱松廷, 高卫时, 张立明. 甜菜品系叶丛快速生长期抗旱性综合评价[J]. 新疆农业科学, 2024, 61(9): 2140-2151. |

| [2] | 阿热孜姑·吐逊, 高杰. 干旱胁迫和播种密度对洋葱小鳞茎生理特性及产出鳞茎个数的影响[J]. 新疆农业科学, 2024, 61(9): 2211-2222. |

| [3] | 胡华兵, 孙琳琳, 刘建雄, 贺碧微, 刘珣, 郇町, 李有芳. 滴灌甜菜糖分积累与温度的相关性分析[J]. 新疆农业科学, 2024, 61(8): 1916-1925. |

| [4] | 叶萍毅, 龙遗磊, 谭彦平, 杜霄, 安梦洁, 陶志鑫, 梁发瑞, 艾先涛, 胡守林. 陆地棉果枝夹角与机采农艺性状鉴定评价[J]. 新疆农业科学, 2024, 61(6): 1318-1327. |

| [5] | 阿不都卡地尔·库尔班, 潘竟海, 陈友强, 刘华君, 董心久, 白晓山, 李思忠, 高卫时, 沙红, 李小惠. 基于产量相关性状综合评价晚播甜菜品种的适应性[J]. 新疆农业科学, 2024, 61(6): 1368-1377. |

| [6] | 高沐甜, 肖艳梅, 廖志杰, 黄成. 玉米-大刍草渗入系群体籽粒及品质性状的综合评价[J]. 新疆农业科学, 2024, 61(4): 885-891. |

| [7] | 马合木提·阿不来提, 木合塔尔·扎热, 米热古力·外力, 哈地尔·依沙克. 核桃叶缘焦枯病与其养分含量的相关性回归分析[J]. 新疆农业科学, 2024, 61(4): 945-953. |

| [8] | 李晓娟, 赵文菊, 尕桑, 邓昌蓉, 赵孟良, 任延靖. 不同海拔高度芜菁营养成分分析[J]. 新疆农业科学, 2024, 61(3): 652-664. |

| [9] | 杨明花, 廖必勇, 刘强, 冯国瑞, 达吾来·杰克山, 布阿依夏木·那曼提, 刘琪, 艾尔居玛·吐卢汗, 彭云承. 基于主成分分析的玉米杂交组合脱水性综合评价[J]. 新疆农业科学, 2024, 61(2): 318-325. |

| [10] | 王季姣, 潘越, 王世伟, 韩政伟, 马勇, 虎海防, 王宝庆. 土壤养分与北冰红山葡萄果实品质间的典型相关性分析[J]. 新疆农业科学, 2024, 61(2): 355-364. |

| [11] | 杨存明, 张晓雪, 张梦华, 赵志文, 李峰洁, 黄锡霞, 李杰, 艾孜买提·阿吾提, 何军敏, 李雪, 李婷婷, 唐丽, 张文静, 田月珍, 田可川. 细毛羊育种目标性状的相关关系及差异分析[J]. 新疆农业科学, 2024, 61(2): 514-520. |

| [12] | 李春雨, 谭占明, 程云霞, 高源, 马全会, 李志国, 马兴. 水肥耦合对沙培番茄叶绿素含量以及光合特性日变化的影响[J]. 新疆农业科学, 2024, 61(12): 3006-3013. |

| [13] | 徐斌, 王征, 宋占腾, 玛尔哈巴·帕尔哈提, 朱靖蓉, 车凤斌, 李永海, 武凤艳, 苗福红. 11份野生沙棘种质资源果实品质分析与综合评价[J]. 新疆农业科学, 2024, 61(12): 3020-3031. |

| [14] | 马钥珺, 谭占明, 程云霞, 吴慧, 张乔乔, 杜佳庚, 王琦, 崔贺伟, 马兴. 不同基质配比及砧穗组合对黄瓜生长发育的影响[J]. 新疆农业科学, 2024, 61(11): 2635-2647. |

| [15] | 赵文轩, 程云霞, 谭占明, 李春雨, 束胜, 阿依买木·沙吾提, 杨历雨, 苗献军. 基于主成分分析比较不同加工番茄品种叶绿素的荧光参数及光合特性[J]. 新疆农业科学, 2024, 61(11): 2667-2675. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||