新疆农业科学 ›› 2023, Vol. 60 ›› Issue (12): 3102-3112.DOI: 10.6048/j.issn.1001-4330.2023.12.028

• 畜牧兽医·微生物·农业装备工程与机械化 • 上一篇 下一篇

张伟1( ), 靳范1,2(

), 靳范1,2( ), 李谦绪2, 张俊三2, 翟修萍2, 王善博1

), 李谦绪2, 张俊三2, 翟修萍2, 王善博1

收稿日期:2023-04-27

出版日期:2023-12-20

发布日期:2024-01-03

通信作者:

靳范(1968-),男,新疆乌鲁木齐人,提高待遇高级工程师,硕士生导师,研究方向为农业机械装备工程,(E-mail)639916709@qq.com

作者简介:张伟(1997-),男,陕西安康人,硕士研究生,研究方向为农业机械装备,(E-mail)1213869102@qq.com

基金资助:

ZHANG Wei1( ), JIN Fan1,2(

), JIN Fan1,2( ), LI Qianxu2, ZHANG Junsan2, ZHAI Xiuping2, WANG Shanbo1

), LI Qianxu2, ZHANG Junsan2, ZHAI Xiuping2, WANG Shanbo1

Received:2023-04-27

Online:2023-12-20

Published:2024-01-03

Correspondence author:

JIN Fan (1968-), male, from Urumqi, senior engineer with improved salary, bachelor degree,Resticide direction:agricultural machinery engineering,(E-mail)Supported by:摘要:

【目的】设计玉米籽粒联合收获机风机与双层鱼鳞筛网组合式清选装置,分析风筛装置参数,优化清选装置作业参数,降低清选装置的损失率和含杂率。【方法】对清选装置建立数学模型进行理论分析计算。寻找影响清选装置的因素,利用ADAMS建立运动仿真模型,仿真分析得出运动筛加速度特征曲线。优化设计分析清选风机蜗壳主要参数,以玉米籽粒含杂率和籽粒损失率为试验指标,以风机转速、振动频率、筛网开度为试验因素。采用Box-Behnken中心组合试验设计,建立试验因素与试验指标之间的回归模型。分析清选装置上的物料三种不同运动状态,计算得出清选筛合理的加速度范围。通过对振动筛连杆数学建模分析得出影响籽粒清选效果的主要因素。【结果】当风机转速为1 050 r/min,振动频率为6 Hz,筛网开度为17 mm时。玉米籽粒含杂率为0.94%,清选损失率为1.19%。【结论】优化后的清选装置各项参数满足行业要求。

中图分类号:

张伟, 靳范, 李谦绪, 张俊三, 翟修萍, 王善博. 玉米籽粒联合收获机清选装置优化设计与试验[J]. 新疆农业科学, 2023, 60(12): 3102-3112.

ZHANG Wei, JIN Fan, LI Qianxu, ZHANG Junsan, ZHAI Xiuping, WANG Shanbo. Design and experiment of cleaning device for corn grain combine harvester[J]. Xinjiang Agricultural Sciences, 2023, 60(12): 3102-3112.

| 项目 Item | 参数 Parameters |

|---|---|

| 试验品种 Test varieties | 九圣禾2468 |

| 作物产量 Crop yield(g/m2) | 1 884.1 |

| 百粒质量 Hundred grain quality(g) | 53.1 |

| 作物自然高度 Natural height of the crop (mm) | 2712 |

| 株距 Plant spacing (mm) | 214 |

| 行距 Row spacing (mm) | 466 |

| 单穗籽粒质量 Seed mass per ear (g) | 176.7 |

| 单株果穗质量 Ear weight per plant (g) | 561.2 |

| 最低结穗高度 Minimum spike height (mm) | 1 099 |

| 籽粒含水率 Seed moisture content(%) | 26.88 |

表1 田间试验条件

Tab.1 Field test conditions

| 项目 Item | 参数 Parameters |

|---|---|

| 试验品种 Test varieties | 九圣禾2468 |

| 作物产量 Crop yield(g/m2) | 1 884.1 |

| 百粒质量 Hundred grain quality(g) | 53.1 |

| 作物自然高度 Natural height of the crop (mm) | 2712 |

| 株距 Plant spacing (mm) | 214 |

| 行距 Row spacing (mm) | 466 |

| 单穗籽粒质量 Seed mass per ear (g) | 176.7 |

| 单株果穗质量 Ear weight per plant (g) | 561.2 |

| 最低结穗高度 Minimum spike height (mm) | 1 099 |

| 籽粒含水率 Seed moisture content(%) | 26.88 |

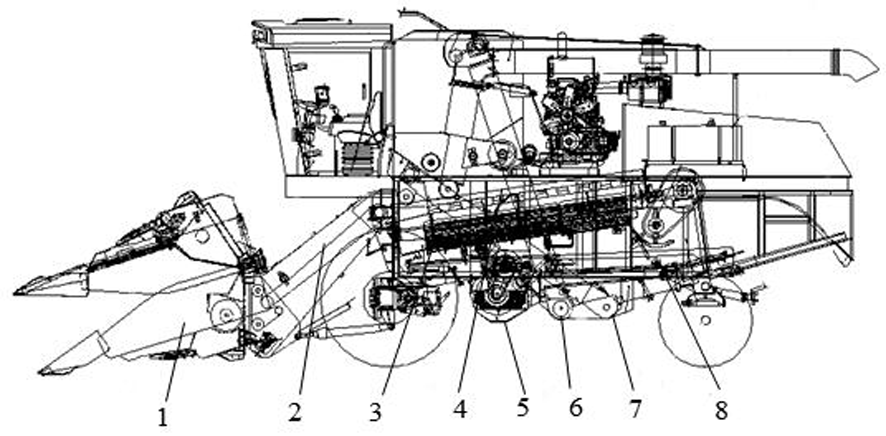

图1 玉米联合收获机结构示意 注:1.折叠割台;2.过桥;3.轴流滚筒;4.凹板;5.风机;6.粮食搅龙;7.杂余搅龙;8.清选筛

Fig.1 Structure diagram of corn combine harvester Note:1.Folding header;2.Bridge;3.Axial flow drum;4.Concave plate;5.Fan;6.Grain auger;7.Miscellaneous auger;8.Cleaning screen

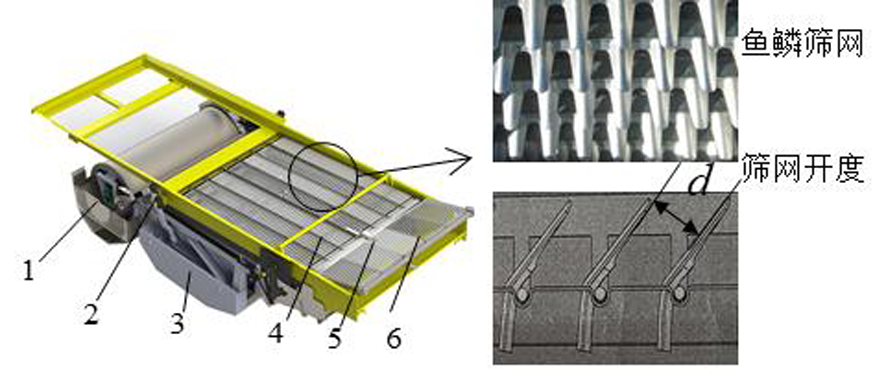

图2 玉米籽粒清选装置结构 注:1.风机;2.曲柄连杆;3.籽粒收集箱;4.鱼鳞上筛;5.鱼鳞筛调节把手;6.尾筛

Fig.2 Structure diagram of corn kernel cleaning device Note:1.Fan;2.Crank connecting rod;3.Grain collection box;4.Fish scale upper screen;5.Fish scale screen adjusting handle;6.Tail screen

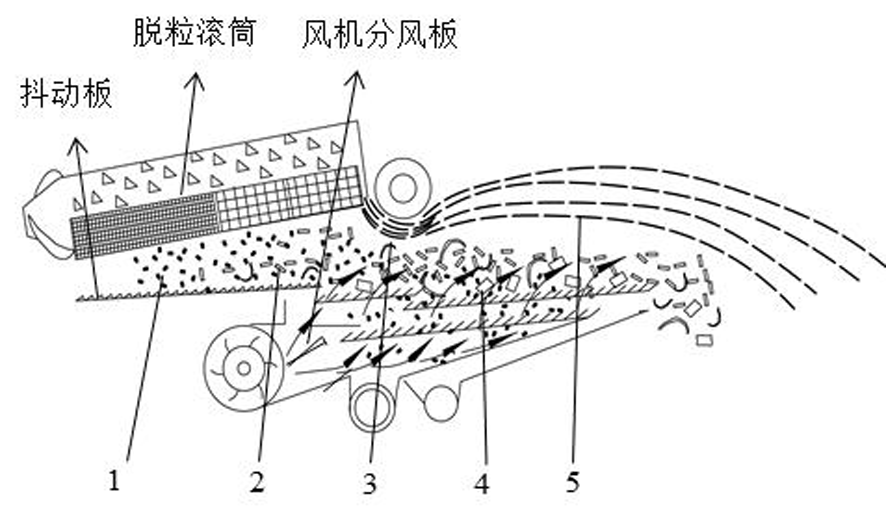

图3 清选分离作业示意 注:1.玉米籽粒;2.碎茎秆;3.玉米茎叶;4.碎玉米芯;5.茎秆与芯轴混合杂质

Fig.3 Schematic diagram of cleaning and separation operations Note:1.corn kernels;2.broken stalks;3.corn stalks and leaves;4.broken corn cobs;5.mixed impurities of stalks and cobs

| 优化方案 Optimised solutions | 蜗壳出口 扩张角θ Worm shell outlet expansion angleθ(°) | 蜗舌半径r Snail tongue radius r (mm) |

|---|---|---|

| 优化前 Before optimization | 25 | 15 |

| 优化后 After optimisation | 35 | 6 |

表2 蜗壳优化前后参数对比

Tab.2 Comparison of parameters before and after volute optimization

| 优化方案 Optimised solutions | 蜗壳出口 扩张角θ Worm shell outlet expansion angleθ(°) | 蜗舌半径r Snail tongue radius r (mm) |

|---|---|---|

| 优化前 Before optimization | 25 | 15 |

| 优化后 After optimisation | 35 | 6 |

| 风机转速 Fan speed (r/min) | 优化前风量 Airflow before optimisation (m3/h) | 优化后风量 Optimised airflow (m3/h) | 效率提升 Efficiency gains (%) |

|---|---|---|---|

| 850 | 5 568 | 6 016 | 8 |

| 1 040 | 6 122 | 6 568 | 7.3 |

| 1 130 | 6 676 | 7 136 | 6.9 |

表3 风机蜗壳优化前后风量测试

Tab.3 Air volume test before and after fan volute optimization

| 风机转速 Fan speed (r/min) | 优化前风量 Airflow before optimisation (m3/h) | 优化后风量 Optimised airflow (m3/h) | 效率提升 Efficiency gains (%) |

|---|---|---|---|

| 850 | 5 568 | 6 016 | 8 |

| 1 040 | 6 122 | 6 568 | 7.3 |

| 1 130 | 6 676 | 7 136 | 6.9 |

| 编码 Coding | 风机转速 Fan speed (r/min) | 振动频率 Vibration frequency (HZ) | 筛网开度 Screen opening (mm) |

|---|---|---|---|

| 1 | 1 200 | 8 | 22 |

| 0 | 1 050 | 6 | 16 |

| -1 | 900 | 4 | 10 |

表4 试验因素编码

Tab.4 Coding of experimental factors

| 编码 Coding | 风机转速 Fan speed (r/min) | 振动频率 Vibration frequency (HZ) | 筛网开度 Screen opening (mm) |

|---|---|---|---|

| 1 | 1 200 | 8 | 22 |

| 0 | 1 050 | 6 | 16 |

| -1 | 900 | 4 | 10 |

| 序号 Serial number | 风机转速 Fan speed A | 振动频率 Vibration frequency B | 筛网开度 Screen opening C | 籽粒 含杂率 Seed trash content T1(%) | 清选 损失率 Clearance loss rate T1(%) |

|---|---|---|---|---|---|

| 1 | 0 | 0 | 0 | 1.39 | 0.91 |

| 2 | -1 | -1 | 0 | 1.62 | 1.65 |

| 3 | 0 | -1 | 1 | 1.54 | 2.17 |

| 4 | 0 | 0 | 0 | 0.9 | 1.35 |

| 5 | 0 | 0 | 0 | 1.24 | 0.86 |

| 6 | 0 | 0 | 0 | 0.72 | 1.02 |

| 7 | 1 | 0 | 1 | 0.49 | 2.84 |

| 8 | 0 | 1 | 1 | 1.59 | 1.53 |

| 9 | 1 | 0 | -1 | 0.77 | 1.72 |

| 10 | 1 | 1 | 0 | 1.4 | 2.16 |

| 11 | 0 | 1 | -1 | 3.24 | 1.38 |

| 12 | 1 | -1 | 0 | 0.4 | 3.4 |

| 13 | -1 | 1 | 0 | 2.13 | 2.36 |

| 14 | -1 | 0 | 1 | 1.92 | 1.18 |

| 15 | -1 | 0 | -1 | 2.69 | 1.57 |

| 16 | 0 | -1 | -1 | 2.39 | 1.74 |

| 17 | 0 | 0 | 0 | 1.01 | 1.09 |

表5 玉米籽粒清选装置

Tab.5 Test scheme and results of corn grain cleaning device

| 序号 Serial number | 风机转速 Fan speed A | 振动频率 Vibration frequency B | 筛网开度 Screen opening C | 籽粒 含杂率 Seed trash content T1(%) | 清选 损失率 Clearance loss rate T1(%) |

|---|---|---|---|---|---|

| 1 | 0 | 0 | 0 | 1.39 | 0.91 |

| 2 | -1 | -1 | 0 | 1.62 | 1.65 |

| 3 | 0 | -1 | 1 | 1.54 | 2.17 |

| 4 | 0 | 0 | 0 | 0.9 | 1.35 |

| 5 | 0 | 0 | 0 | 1.24 | 0.86 |

| 6 | 0 | 0 | 0 | 0.72 | 1.02 |

| 7 | 1 | 0 | 1 | 0.49 | 2.84 |

| 8 | 0 | 1 | 1 | 1.59 | 1.53 |

| 9 | 1 | 0 | -1 | 0.77 | 1.72 |

| 10 | 1 | 1 | 0 | 1.4 | 2.16 |

| 11 | 0 | 1 | -1 | 3.24 | 1.38 |

| 12 | 1 | -1 | 0 | 0.4 | 3.4 |

| 13 | -1 | 1 | 0 | 2.13 | 2.36 |

| 14 | -1 | 0 | 1 | 1.92 | 1.18 |

| 15 | -1 | 0 | -1 | 2.69 | 1.57 |

| 16 | 0 | -1 | -1 | 2.39 | 1.74 |

| 17 | 0 | 0 | 0 | 1.01 | 1.09 |

| 指标 Indicators | 来源 Source | 平方和 Sum of squares | Df | 均方 Mean square | F值 F value | P值 P value | 显著性 Significance |

|---|---|---|---|---|---|---|---|

| T1 | Model | 9.06 | 9 | 1.01 | 8.39 | 0.005 2 | ** |

| A | 3.51 | 1 | 3.51 | 29.30 | 0.001 0 | ** | |

| B | 0.73 | 1 | 0.73 | 6.06 | 0.043 4 | * | |

| C | 1.58 | 1 | 1.58 | 13.14 | 0.008 4 | ** | |

| AB | 0.06 | 1 | 0.06 | 0.50 | 0.502 0 | ||

| AC | 0.06 | 1 | 0.06 | 0.50 | 0.502 0 | ||

| BC | 0.16 | 1 | 0.16 | 1.33 | 0.285 8 | ||

| A2 | 0.16 | 1 | 0.16 | 1.32 | 0.289 1 | ||

| B2 | 1.18 | 1 | 1.18 | 9.83 | 0.016 5 | * | |

| C2 | 1.56 | 1 | 1.56 | 13.03 | 0.008 6 | ** | |

| 残差 | 0.84 | 7 | 0.12 | ||||

| 失拟项 | 0.55 | 3 | 0.18 | 2.60 | 0.189 6 | ||

| 误差 | 0.28 | 4 | 0.071 | ||||

| 总和 | 9.89 | 16 | |||||

| T2 | Model | 7.58 | 9 | 0.84 | 31.53 | <0.000 1 | ** |

| A | 1.41 | 1 | 1.41 | 52.83 | 0.000 2 | ** | |

| B | 0.29 | 1 | 0.29 | 10.95 | 0.012 9 | * | |

| C | 0.21 | 1 | 0.21 | 8.03 | 0.025 3 | * | |

| AB | 0.95 | 1 | 0.95 | 35.59 | 0.000 6 | ** | |

| AC | 0.57 | 1 | 0.57 | 21.34 | 0.002 4 | ** | |

| BC | 0.02 | 1 | 0.02 | 0.73 | 0.420 0 | ||

| A2 | 2.27 | 1 | 2.27 | 85.03 | <0.000 1 | ** | |

| B2 | 1.58 | 1 | 1.58 | 59.03 | 0.000 1 | ** | |

| C2 | 0.009 3 | 1 | 0.009 3 | 0.35 | 0.573 7 | ||

| 残差 | 0.19 | 7 | 0.027 | ||||

| 失拟项 | 0.039 | 3 | 0.013 | 0.35 | 0.792 6 | ||

| 误差 | 0.15 | 4 | 0.037 | ||||

| 总和 | 7.77 | 16 |

表6 籽粒含杂率方差

Tab.6 Variance analysis of grain impurity rate

| 指标 Indicators | 来源 Source | 平方和 Sum of squares | Df | 均方 Mean square | F值 F value | P值 P value | 显著性 Significance |

|---|---|---|---|---|---|---|---|

| T1 | Model | 9.06 | 9 | 1.01 | 8.39 | 0.005 2 | ** |

| A | 3.51 | 1 | 3.51 | 29.30 | 0.001 0 | ** | |

| B | 0.73 | 1 | 0.73 | 6.06 | 0.043 4 | * | |

| C | 1.58 | 1 | 1.58 | 13.14 | 0.008 4 | ** | |

| AB | 0.06 | 1 | 0.06 | 0.50 | 0.502 0 | ||

| AC | 0.06 | 1 | 0.06 | 0.50 | 0.502 0 | ||

| BC | 0.16 | 1 | 0.16 | 1.33 | 0.285 8 | ||

| A2 | 0.16 | 1 | 0.16 | 1.32 | 0.289 1 | ||

| B2 | 1.18 | 1 | 1.18 | 9.83 | 0.016 5 | * | |

| C2 | 1.56 | 1 | 1.56 | 13.03 | 0.008 6 | ** | |

| 残差 | 0.84 | 7 | 0.12 | ||||

| 失拟项 | 0.55 | 3 | 0.18 | 2.60 | 0.189 6 | ||

| 误差 | 0.28 | 4 | 0.071 | ||||

| 总和 | 9.89 | 16 | |||||

| T2 | Model | 7.58 | 9 | 0.84 | 31.53 | <0.000 1 | ** |

| A | 1.41 | 1 | 1.41 | 52.83 | 0.000 2 | ** | |

| B | 0.29 | 1 | 0.29 | 10.95 | 0.012 9 | * | |

| C | 0.21 | 1 | 0.21 | 8.03 | 0.025 3 | * | |

| AB | 0.95 | 1 | 0.95 | 35.59 | 0.000 6 | ** | |

| AC | 0.57 | 1 | 0.57 | 21.34 | 0.002 4 | ** | |

| BC | 0.02 | 1 | 0.02 | 0.73 | 0.420 0 | ||

| A2 | 2.27 | 1 | 2.27 | 85.03 | <0.000 1 | ** | |

| B2 | 1.58 | 1 | 1.58 | 59.03 | 0.000 1 | ** | |

| C2 | 0.009 3 | 1 | 0.009 3 | 0.35 | 0.573 7 | ||

| 残差 | 0.19 | 7 | 0.027 | ||||

| 失拟项 | 0.039 | 3 | 0.013 | 0.35 | 0.792 6 | ||

| 误差 | 0.15 | 4 | 0.037 | ||||

| 总和 | 7.77 | 16 |

| [1] | 王建廷, 李耀明, 马征, 等. 玉米收获机械关键装置结构特点及发展趋势[J]. 农机化研究, 2019, 41(9):1-8. |

| WANG Jianting, LI Yaoming, MA Zheng, et al. Structural characteristics and development trend of key devices of corn harvesting machinery[J]. Agricultural Mechanization Research, 2019, 41(9):1-8. | |

| [2] | 陈志, 郝付平, 王锋德, 等. 中国玉米收获技术与装备发展研究[J]. 农业机械学报, 2012, 43(12):44-50. |

| ChEN Zhi, HAO Fuping, WANG Fengde, et al. Research on the development of corn harvesting technology and equipment in China[J]. Journal of Agricultural Machinery, 2012, 43(12):44-50. | |

| [3] | 宗望远, 廖庆喜, 黄鹏, 等. 组合式油菜脱粒装置设计与物料运动轨迹分析[J]. 农业机械学报, 2013, 44(S2):41-46. |

| ZONG Wangyuan, LIAO Qingxi, HUANG Peng, et al. Design of combined rape threshing device and analysis of material trajectory[J]. Journal of Agricultural Machinery, 2013, 44 (S2) :41-46. | |

| [4] | 徐立章, 李耀明, 王成红, 等. 切纵流双滚筒联合收获机脱粒分离装置[J]. 农业机械学报, 2014, 45(2):105-108,135. |

| XU Lizhang, LI Yaoming, WANG Chenghong, et al. Threshing separation device of tangential and longitudinal flow double drum combine harvester[J]. Journal of Agricultural Machinery, 2014, 45 (2) :105-108,135. | |

| [5] | 李耀明, 王成红, 徐立章, 等. 切纵流联合收获机脱粒分离装置田间试验与参数优化[J]. 农业机械学报, 2014, 45(11):111-116. |

| LI Yaoming, WANG Chenghong, XU Lizhang, et al. Field experiment and parameter optimization of threshing and separating device of tangential-longitudinal flow combine harvester[J]. Journal of Agricultural Machinery, 2014, 45(11):111-116. | |

| [6] | 司增永, 李耀明, 唐忠, 等. 横置多滚筒联合收获机清选装置参数优化与试验[J]. 农机化研究, 2018, 40(7):185-189,205. |

| SI Zengyong, LI Yaoming, TANG Zhong, et al. Parameter optimization and test of cleaning device for transverse multi-roller combine harvester[J]. Agricultural Mechanization Research, 2018, 40 (07) :185-189,205. | |

| [7] | 司增永. 多滚筒联合收获机清选装置设计与试验[D]. 镇江: 江苏大学, 2017. |

| SI Zengyong. Design and test of cleaning device for multi-drum combine harvester[D]. Zhenjiang: Jiangsu University, 2017. | |

| [8] | 钟挺, 胡志超, 顾峰玮, 等. 4LZ-1.0Q型稻麦联合收获机脱粒清选部件试验与优化[J]. 农业机械学报, 2012, 43(10):76-81. |

| ZHONG Ting, HU Zhichao, GU Fengwei, et al. 4LZ-1.0Q rice-wheat combine threshing and cleaning components test and optimization[J]. Journal of Agricultural Machinery, 2012, 43 (10) :76-81. | |

| [9] | 钟挺, 胡志超, 顾峰玮, 等. 轻简型全喂入稻麦联合收获清选装置分析及设计要点探析[J]. 中国农机化, 2012,(6):67-70,77. |

| ZHONG Ting, HU Zhichao, GU Fengwei, et al. Analysis and design of light and simple full-feed rice-wheat combined harvest cleaning device[J]. China Agricultural Mechanization, 2012,(6):67-70,77. | |

| [10] | 樊晨龙, 崔涛, 张东兴. 等. 纵轴流联合收获机双层异向清选装置设计与试验[J]. 农业机械学报, 2018, 49(S1):239-248. |

| FAN Chenlong, CUI Tao, ZHANG Dongxing, et al. Design and test of two-layer opposite cleaning device for longitudinal and axial flow combine harvester[J]. Journal of Agricultural Machinery, 2018, 49 (S1) :239-248. | |

| [11] | 栗晓宇, 杜岳峰, 牛兴成, 等. 玉米清选装置结构优化设计与试验[J]. 农业机械学报, 2020, 51(S2):233-242. |

| LI Xiaoyu, DU Yuefeng, NIU Xingcheng, et al. Structural optimization design and test of corn cleaning device[J]. Journal of Agricultural Machinery, 2020, 51 (S2) :233-242. | |

| [12] | 王立军, 刘伟腾, 李懿航, 等. 大喂入量玉米籽粒收获机清选系统双层筛孔抖动板研究[J]. 农业机械学报:1-12[2022-06-27]. |

| WANG Lijun, LIU Weiteng, LI Yihang, et al. Research on double-layer sieve shaker plate for cleaning system of corn grain harvester with large feed rate[J]. Journal of Agricultural Machinery:1-12 [2022-06-27]. | |

| [13] | Ali M, Shamsollah A, Asghar M, et al. Intelligent modeling of material separation in combine harvester’s thresher by ANN[J]. International Journal of Agriculture and Crop Sciences, 2012, 4(23):1767-1777. |

| [14] |

LIANG Z W, XU L Z, Baerdemaeker J D, et al. Optimization of a multi-duct cleaning device for rice combine harvesters utilising CFD and experiments[J]. Biosystems Engineering, 2020, 190:25 -40.

DOI URL |

| [15] | 中国农业机械化科学研究院. 农业机械设计手册[M]. 北京: 中国农业科学技术出版社, 2007. |

| Chinese Academy of Agricultural Mechanization. Manual of Agricultural Machinery Design[M]. Beijing: China Agricultural Science and Technology Press, 2007. | |

| [16] | 李耀明, 王智华, 徐立章, 等. 油菜脱出物振动筛分运动分析及试验研究[J]. 农业工程学报, 2007,(9):111-114. |

| LI Yaoming, WANG Zhihua, XU Lizhang, et al. Motion analysis and experimental study on vibration screening of rapeseed extract[J]. Transactions of the Chinese Society of Agricultural Engineering, 2007,(9):111-114. | |

| [17] | 于昭洋, 胡志超, 曹明珠, 等. 切流式花生全喂入联合收获机清选机构设计[J]. 农业工程学报, 2019, 35(9):29-37. |

| YU Zhaoyang, HU Zhichao, CAO Mingzhu, et al. The cleaning mechanism design of tangential peanut full-feed combine harvester[J]. Transactions of the Chinese Society of Agricultural Engineering, 2019, 35 (9) :29-37. | |

| [18] | 贾晶霞, 张东兴. 马铃薯收获机摆动筛与块茎运动仿真分析[J]. 中国农业大学学报, 2006,(3):79-82. |

| JIA Jingxia, ZHANG Dongxing. Simulation Analysis of Potato Harvester Oscillating Screen and Tuber Movement[J]. Journal of China Agricultural University, 2006,(3):79-82. | |

| [19] | 卢琦, 徐兵, 刘芸, 等. 基于ADAMS的往复式谷物振动筛设计与试验[J]. 山西农业大学学报(自然科学版), 2019, 39(2):98-104. |

| LU Qi, XU Bing, LIU Yun. et al. Design and experiment of reciprocating grain shaker based on ADAMS[J]. Journal of Shanxi Agricultural University (Natural Science Ed.), 2019, 39(2):98- 104. | |

| [20] |

张磊, 黄康, 黄国兴, 等. 离心风机蜗壳出口结构优化研究[J]. 流体机械, 2019, 47(6):47-51.

DOI |

| ZHANG Lei, HUANG Kang, HUANG Guoxing, et al. Research on the optimization of the outlet structure of the centrifugal fan volute[J]. Fluid Machinery, 2019, 47(6):47-51. | |

| [21] | 王加浩, 刘小民, 田晨晔, 等. 多翼离心风机双圆弧叶片的参数优化设计及气动性能分析[J]. 西安交通大学学报, 2022, 56(3):94-104. |

| WANG Jiahao, LIU Xiaomin, TIAN Chenye, et al. Parameter optimization design and aerodynamic performance analysis of double-arc blades for multi-wing centrifugal fan[J]. Journal of Xi'an Jiaotong University, 2022, 56(3):94-104. |

| [1] | 王登峰, 古努尔·吐尔逊, 李建军, 洪都孜·波拉提, 杨学云, 孟肖潇, 吴建勇. 奶山羊CAEV感染血清抗体的消长规律[J]. 新疆农业科学, 2023, 60(6): 1555-1560. |

| [2] | 王金武, 王钊英, 于万里, 蒋永新, 杨会民, 张佳喜. 残膜回收机自动仿形系统及关键部件的运动分析与试验[J]. 新疆农业科学, 2023, 60(11): 2842-2852. |

| [3] | 冯贝贝, 梅闯, 王磊, 耿文娟, 阿孜古丽·衣该木, 闫鹏, 王继勋. 阿克苏富士苹果烟富3号化学疏花疏果的效果[J]. 新疆农业科学, 2023, 60(10): 2470-2478. |

| [4] | 谭新赞, 沈从举, 代亚猛, 李帆, 贾首星, 蒙贺伟. 1SZL-300型振动深松整地联合作业机的研制[J]. 新疆农业科学, 2023, 60(10): 2566-2573. |

| [5] | 杜月梅, 高丽萍, 邵华. 呋虫胺及其代谢物UF和DN在水稻上残留行为及其储存稳定性[J]. 新疆农业科学, 2022, 59(3): 663-673. |

| [6] | 毛吾兰, 祝兆帅, 杨莉玲, 崔宽波, 朱占江. 杏果切分去核机构优化及作业参数分析[J]. 新疆农业科学, 2022, 59(12): 3084-3092. |

| [7] | 杨庭瑞, 赵经华, 杨磊, 彭艳平, 周和平. 基于正交试验的玉米最优产量渗灌技术组合分析[J]. 新疆农业科学, 2021, 58(9): 1585-1593. |

| [8] | 张丽, 边博, 吐鲁洪·吐尔迪, 王学农. 气吸式巴旦木壳仁风选装置试验与优化分析[J]. 新疆农业科学, 2021, 58(8): 1540-1546. |

| [9] | 王洪博, 杨莹攀, 高阳, 周宇, 孙文君, 王兴鹏. 环境因子对无膜滴灌棉种萌发特性的影响[J]. 新疆农业科学, 2021, 58(3): 430-440. |

| [10] | 吴小媚, 袁延平, 魏肖如, 曹福祥, 陈己任, 吕长平, 李玉帆. 预处理及培养方法协同作用对新铁炮百合种子萌发的影响[J]. 新疆农业科学, 2020, 57(7): 1276-1286. |

| [11] | 阿米热·牙生江, 阿地力·沙塔尔, 付开赟, 丁新华, 何江, 吐尔逊·阿合买提, 郭文超, 李晓维. 9种杀虫剂对番茄潜叶蛾的防治效果评价[J]. 新疆农业科学, 2020, 57(12): 2291-2298. |

| [12] | 李飞, 李彩红, 赵瑞元, 梅正鼎, 郭莉莉, 刘冰蕾, 何叔军, 张志刚. 湖南省油后直播棉花测土配方施肥指标体系[J]. 新疆农业科学, 2020, 57(11): 1961-1970. |

| [13] | 朱静, 张志东, 刘晓静, 唐琦勇, 王博, 顾美英, 宋素琴, 王玮, 张丽娟. 黑色素与生物农药配伍优化及其对棉田产量的影响[J]. 新疆农业科学, 2018, 55(9): 1728-1736. |

| [14] | 王宁, 侯敏, 房世杰, 艾尼江·尔斯满, 侯新强, 杨蓉, 包慧芳. 红枣黑斑病拮抗细菌JK1产芽孢培养基的优化[J]. 新疆农业科学, 2018, 55(6): 1098-1106. |

| [15] | 徐强, 王卫超, 许咏梅, 邵华伟, 杨金钰, 乔晓燕, 吕彩霞. 化肥减施-有机肥替代措施提高新疆甜瓜产量和含糖量研究[J]. 新疆农业科学, 2017, 54(8): 1450-1459. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||