新疆农业科学 ›› 2024, Vol. 61 ›› Issue (10): 2500-2513.DOI: 10.6048/j.issn.1001-4330.2024.10.018

• 植物保护·土壤肥料·节水灌溉·农业装备工程与机械化·草业 • 上一篇 下一篇

徐路明1( ), 靳范1,2(

), 靳范1,2( ), 张俊三1,2, 阿力木·买买提吐尔逊1,2, 李谦绪2, 孙利峰2

), 张俊三1,2, 阿力木·买买提吐尔逊1,2, 李谦绪2, 孙利峰2

收稿日期:2024-03-28

出版日期:2024-10-20

发布日期:2024-11-07

通信作者:

靳范(1968-),男,新疆乌鲁木齐人,提高待遇高级工程师,研究方向为农业机械化技术装备,(E-mail)639916709@qq.com作者简介:徐路明(1997-),男,辽宁鞍山人,硕士研究生,研究方向为现代农业机械装备,(E-mail)1067029962@qq.com

基金资助:

XU Luming1( ), JIN Fan1,2(

), JIN Fan1,2( ), ZHANG Junsan1,2, Alimu Maimaitituerxun1,2, LI Qianxu2, SUN Lifeng2

), ZHANG Junsan1,2, Alimu Maimaitituerxun1,2, LI Qianxu2, SUN Lifeng2

Received:2024-03-28

Published:2024-10-20

Online:2024-11-07

Correspondence author:

JIN Fan(1968-), male, from Urumqi, Xinjiang,senior engineer with improved salary, research direction:Agriculture Mechanization Technology and Equipment,(E-mail)639916709@qq.comSupported by:摘要:

【目的】 针对玉米脱粒过程中易出现脱粒空间堵塞、滚筒转不动所导致的籽粒破碎率偏高和存在夹带损失的问题,设计一种喂抛组合式脱粒分离装置。【方法】 在滚筒前端的喂入口处设计喂入加速辊,分析对果穗及秸秆受力情况,确定半径为150 mm,并结合过桥输送链耙线速度和玉米脱粒速度,确定转速为430 r/min;分析滚筒工作段型式,优化设计导流罩内导流板角度为喂入段30°、脱粒段20°、分离段10°;在滚筒后端排草口处设计安装排杂抛出装置,包括排草辊和排草凹板。以滚筒转速、凹板间隙、喂入量为试验因素,同时以籽粒破碎率和未脱净率作为评价指标,设计三因素三水平田间正交试验;使用Design-Expert 12软件优化数据。【结果】 在滚筒转速447.11 r/min、凹板间隙34.74 mm、喂入量16.14 kg/s,籽粒破碎率达到2.68%,未脱净率达到0.99%。【结论】 在滚筒转速450 r/min、凹板间隙35 mm、喂入量16 kg/s,平均籽粒破碎率达到2.73%,平均未脱净率达到1.04%,试验结果与优化结果间相对误差在5%以内,装置设计合理,优于传统脱粒分离装置,满足脱粒标准。

中图分类号:

徐路明, 靳范, 张俊三, 阿力木·买买提吐尔逊, 李谦绪, 孙利峰. 玉米籽粒收获机喂抛组合式脱粒分离装置设计与试验[J]. 新疆农业科学, 2024, 61(10): 2500-2513.

XU Luming, JIN Fan, ZHANG Junsan, Alimu Maimaitituerxun, LI Qianxu, SUN Lifeng. Design and experiment of combined threshing and separating device for corn grain harvester[J]. Xinjiang Agricultural Sciences, 2024, 61(10): 2500-2513.

| 参数 Argument | 数值 Numerical value |

|---|---|

| 行距 Line spacing (mm) | 550 |

| 株距 Spacing in rows (mm) | 350 |

| 自然株高 Natural plant height (mm) | 2 943 |

| 最低结穗高度 Minimum heading height (mm) | 1 315 |

| 百粒重 Hundred-grain weight (g) | 35.7 |

| 果穗长 Ear length (mm) | 220 |

| 籽粒含水率 Grain moisture content (%) | 25.2 |

表1 玉米植株及果穗相关参数

Tab.1 Relevant parameters of corn plants and ears

| 参数 Argument | 数值 Numerical value |

|---|---|

| 行距 Line spacing (mm) | 550 |

| 株距 Spacing in rows (mm) | 350 |

| 自然株高 Natural plant height (mm) | 2 943 |

| 最低结穗高度 Minimum heading height (mm) | 1 315 |

| 百粒重 Hundred-grain weight (g) | 35.7 |

| 果穗长 Ear length (mm) | 220 |

| 籽粒含水率 Grain moisture content (%) | 25.2 |

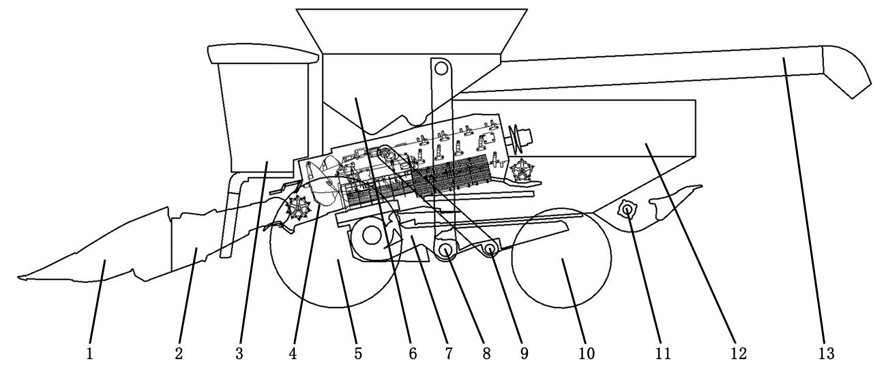

图1 4YZL-13型自走式玉米籽粒收获机结构 注:1.割台;2.过桥;3.驾驶室;4.喂抛组合式脱粒分离装置;5.驱动轮;6.粮仓;7.清选系统;8.粮食绞龙;9.杂余绞龙;10.转向轮;11.切碎器;12.机架;13.卸粮筒

Fig.1 Structure diagram of 4YZL-13 self-propelled corn grain harvester Notes:1.Cutting table;2.Bridge;3.Cab;4.Feed and throw combined threshing separation device;5.Drive wheel;6.Granary;7.Cleaning system;8.Grain winch;9.Miscellaneous winch;10.Steering wheel;11.Chopper;12.Frame;13.Discharge cylinder

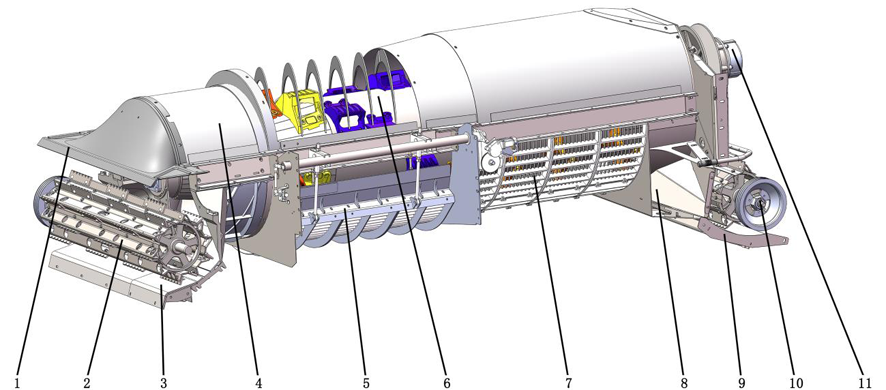

图2 喂抛组合式脱粒分离装置结构示意 注:1.防护罩;2.喂入加速辊;3.喂入口;4.导流罩;5.脱粒凹板;6.单纵轴流滚筒;7.分离凹板;8.排草口;9.排草凹板;10.排草辊;11.变速箱

Fig.2 Structure diagram of feed and throw combined threshing and separating device Notes:1.Shield;2.Feed acceleration roller;3.Feed inlet;4.Guide hood;5.Threshing concave plate;6.Single longitudinal axial flow roller;7.Separation concave plate;8.Straw drain;9.Drain concave plate;10.Drain roller;11.Gearbox

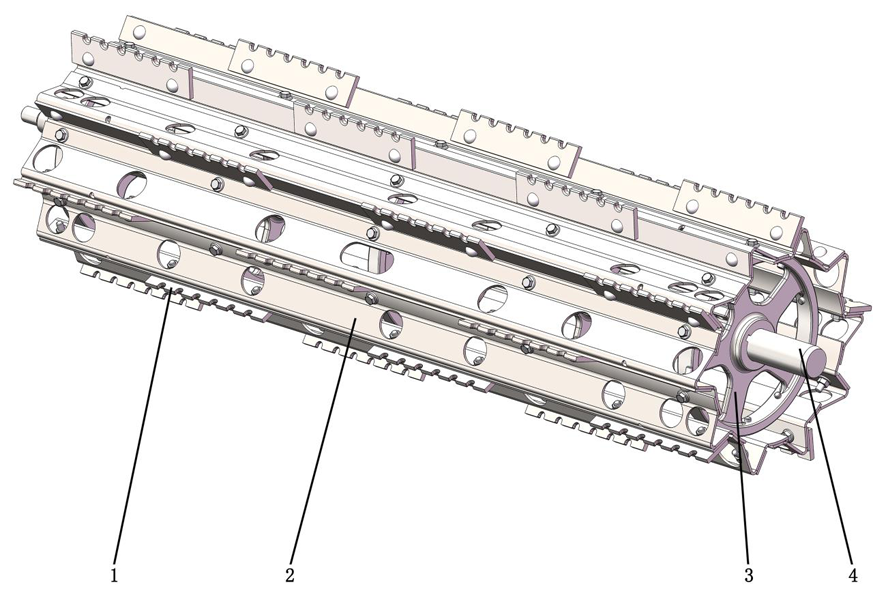

图4 喂入加速辊结构示意 注:1.耐磨拨齿板;2.安装座板;3.支撑轮毂;4.喂入加速辊轴

Fig.4 Structure diagram of feeding acceleration roller Notes:1.Wear-resistant gear plate;2.Mounting plate;3.Supporting wheel hub;4.Feeding acceleration roller

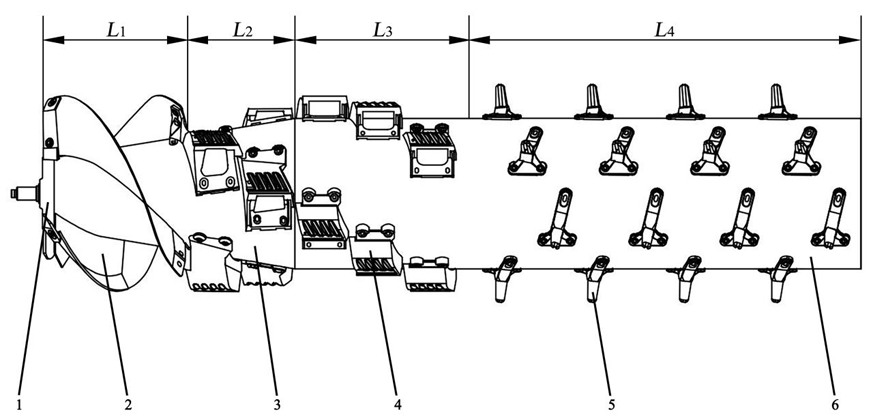

图6 单纵轴流滚筒结构示意 注:1.连接转轴;2.螺旋叶片;3.锥筒;4.脱粒纹杆;5.分离钉齿;6.直筒

Fig.6 Single longitudinal axial flow drum structure diagram Notes:1.Connecting shaft;2.Spiral blade;3.Cone;4.Threshing rod;5.Separation nail teeth;6.Straight barrel

图9 排草辊结构示意 注:1.轴;2.侧轮毂;3.板齿;4.中间轮毂;5.安装支架

Fig.9 Straw roller structure diagram Notes:1.Shaft;2.Side hub;3.Plate tooth;4.Intermediate hub;5.Mounting bracket

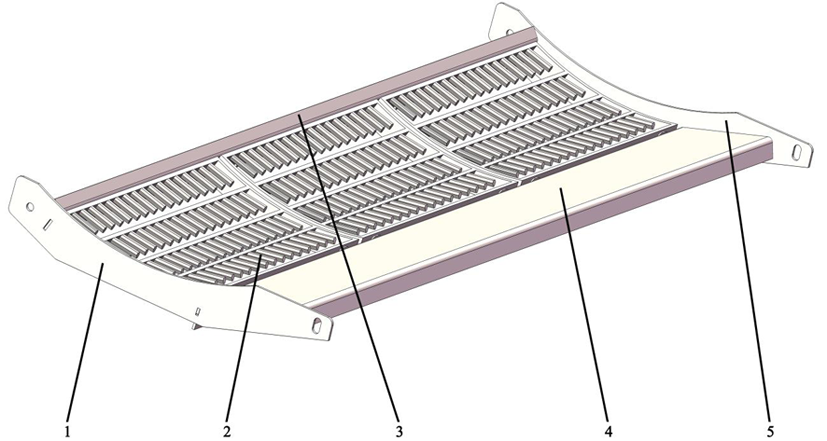

图10 排草凹板结构示意 注:1.左侧板;2.半栅格凹板;3.后安装板;4.前安装板;5.右侧板

Fig.10 The structure diagram of thegrass concave plate Notes:1.Left panel;2.Semi-grid concave panel;3.Rear mounting panel;4.Front mounting panel;5.Right-side plate

| 编码 Coding | 滚筒转速A Drum speed A (r/min) | 凹板间隙B Concave clearance B (mm) | 喂入量C Feed amount C (kg/s) |

|---|---|---|---|

| -1 | 400 | 30 | 16 |

| 0 | 450 | 35 | 17 |

| 1 | 500 | 40 | 18 |

表2 试验因素编码

Tab.2 Test factor coding

| 编码 Coding | 滚筒转速A Drum speed A (r/min) | 凹板间隙B Concave clearance B (mm) | 喂入量C Feed amount C (kg/s) |

|---|---|---|---|

| -1 | 400 | 30 | 16 |

| 0 | 450 | 35 | 17 |

| 1 | 500 | 40 | 18 |

| 序号 Number | 试验因素 Experimental factor | 评价指标 Evaluation index | |||

|---|---|---|---|---|---|

| 滚筒转速A Drum speed A (r/min) | 凹板间隙B Concave clearance B (mm) | 喂入量C Feed amount C (kg/s) | 籽粒破碎率Zs Grain breakage rate Zs (%) | 未脱净率Sw Unstripped rate Sw (%) | |

| 1 | -1 | -1 | 0 | 3.25 | 2.05 |

| 2 | 1 | -1 | 0 | 4.18 | 0.97 |

| 3 | -1 | 1 | 0 | 2.55 | 2.07 |

| 4 | 1 | 1 | 0 | 3.61 | 1.93 |

| 5 | -1 | 0 | -1 | 2.43 | 1.61 |

| 6 | 1 | 0 | -1 | 3.72 | 0.75 |

| 7 | -1 | 0 | 1 | 3.51 | 2.06 |

| 8 | 1 | 0 | 1 | 4.19 | 1.35 |

| 9 | 0 | -1 | -1 | 3.21 | 1.08 |

| 10 | 0 | 1 | -1 | 2.41 | 1.91 |

| 11 | 0 | -1 | 1 | 3.85 | 1.71 |

| 12 | 0 | 1 | 1 | 3.92 | 1.89 |

| 13 | 0 | 0 | 0 | 2.98 | 1.16 |

| 14 | 0 | 0 | 0 | 2.83 | 0.98 |

| 15 | 0 | 0 | 0 | 2.94 | 1.11 |

| 16 | 0 | 0 | 0 | 2.96 | 1.13 |

| 17 | 0 | 0 | 0 | 2.81 | 0.95 |

表3 试验方案与结果

Tab.3 Experimental scheme and results

| 序号 Number | 试验因素 Experimental factor | 评价指标 Evaluation index | |||

|---|---|---|---|---|---|

| 滚筒转速A Drum speed A (r/min) | 凹板间隙B Concave clearance B (mm) | 喂入量C Feed amount C (kg/s) | 籽粒破碎率Zs Grain breakage rate Zs (%) | 未脱净率Sw Unstripped rate Sw (%) | |

| 1 | -1 | -1 | 0 | 3.25 | 2.05 |

| 2 | 1 | -1 | 0 | 4.18 | 0.97 |

| 3 | -1 | 1 | 0 | 2.55 | 2.07 |

| 4 | 1 | 1 | 0 | 3.61 | 1.93 |

| 5 | -1 | 0 | -1 | 2.43 | 1.61 |

| 6 | 1 | 0 | -1 | 3.72 | 0.75 |

| 7 | -1 | 0 | 1 | 3.51 | 2.06 |

| 8 | 1 | 0 | 1 | 4.19 | 1.35 |

| 9 | 0 | -1 | -1 | 3.21 | 1.08 |

| 10 | 0 | 1 | -1 | 2.41 | 1.91 |

| 11 | 0 | -1 | 1 | 3.85 | 1.71 |

| 12 | 0 | 1 | 1 | 3.92 | 1.89 |

| 13 | 0 | 0 | 0 | 2.98 | 1.16 |

| 14 | 0 | 0 | 0 | 2.83 | 0.98 |

| 15 | 0 | 0 | 0 | 2.94 | 1.11 |

| 16 | 0 | 0 | 0 | 2.96 | 1.13 |

| 17 | 0 | 0 | 0 | 2.81 | 0.95 |

| 方差来源 Source of variation | 籽粒破碎率Zs Grain breakage rate Zs (%) | 未脱净率Sw Unstripped rate Sw (%) | ||

|---|---|---|---|---|

| F值 F-value | P | F值 F-value | P | |

| 回归模型Regression model | 39.33 | <0.000 1** | 35.20 | <0.000 1** |

| A | 129.42 | <0.000 1** | 90.40 | <0.000 1** |

| B | 33.01 | 0.000 7** | 45.99 | 0.000 3** |

| C | 112.99 | <0.000 1** | 32.00 | 0.000 8** |

| AB | 0.279 0 | 0.613 7 | 20.52 | 0.002 7** |

| AC | 6.14 | 0.042 3* | 0.522 6 | 0.493 2 |

| BC | 12.49 | 0.009 5** | 9.81 | 0.016 5* |

| A2 | 25.73 | 0.001 4** | 22.91 | 0.002 0** |

| B2 | 9.96 | 0.016 0* | 78.16 | <0.000 1** |

| C2 | 17.97 | 0.003 8** | 7.08 | 0.032 5* |

| 失拟项 Loss of quasi item | 4.43 | 0.092 2 | 1.48 | 0.347 4 |

表4 籽粒破碎率Zs及未脱净率Sw方差的变化

Tab.4 Changes of variance of grain crushing rate Zs and unstripped rate Sw

| 方差来源 Source of variation | 籽粒破碎率Zs Grain breakage rate Zs (%) | 未脱净率Sw Unstripped rate Sw (%) | ||

|---|---|---|---|---|

| F值 F-value | P | F值 F-value | P | |

| 回归模型Regression model | 39.33 | <0.000 1** | 35.20 | <0.000 1** |

| A | 129.42 | <0.000 1** | 90.40 | <0.000 1** |

| B | 33.01 | 0.000 7** | 45.99 | 0.000 3** |

| C | 112.99 | <0.000 1** | 32.00 | 0.000 8** |

| AB | 0.279 0 | 0.613 7 | 20.52 | 0.002 7** |

| AC | 6.14 | 0.042 3* | 0.522 6 | 0.493 2 |

| BC | 12.49 | 0.009 5** | 9.81 | 0.016 5* |

| A2 | 25.73 | 0.001 4** | 22.91 | 0.002 0** |

| B2 | 9.96 | 0.016 0* | 78.16 | <0.000 1** |

| C2 | 17.97 | 0.003 8** | 7.08 | 0.032 5* |

| 失拟项 Loss of quasi item | 4.43 | 0.092 2 | 1.48 | 0.347 4 |

| 序号 Number | 籽粒破碎率Zs Grain breakage rate Zs (%) | 未脱净率Sw Unstripped rate Sw (%) |

|---|---|---|

| 1 | 2.69 | 1.01 |

| 2 | 2.74 | 1.03 |

| 3 | 2.76 | 1.08 |

| 均值 Mean value | 2.73 | 1.04 |

表5 参数优化后试验结果

Tab.5 Experimental results after parameter optimization

| 序号 Number | 籽粒破碎率Zs Grain breakage rate Zs (%) | 未脱净率Sw Unstripped rate Sw (%) |

|---|---|---|

| 1 | 2.69 | 1.01 |

| 2 | 2.74 | 1.03 |

| 3 | 2.76 | 1.08 |

| 均值 Mean value | 2.73 | 1.04 |

| [1] | 耿爱军, 杨建宁, 张兆磊, 等. 国内外玉米收获机械发展现状及展望[J]. 农机化研究, 2016, 38(4): 251-257. |

| GENG Aijun, YANG Jianning, ZHANG Zhaolei, et al. Discuss about the current situation and future of corn harvest machinery about domestic and abroad[J]. Journal of Agricultural Mechanization Research, 2016, 38(4): 251-257. | |

| [2] | 耿端阳, 何珂, 王骞, 等. 横轴流式玉米柔性脱粒装置设计与试验[J]. 农业机械学报, 2019, 50(3): 101-108. |

| GENG Duanyang, HE Ke, WANG Qian, et al. Design and experiment on transverse axial flow flexible threshing device for corn[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(3): 101-108. | |

| [3] | 崔涛, 樊晨龙, 张东兴, 等. 玉米机械化收获技术研究进展分析[J]. 农业机械学报, 2019, 50(12): 1-13. |

| CUI Tao, FAN Chenlong, ZHANG Dongxing, et al. Research progress of maize mechanized harvesting technology[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(12): 1-13. | |

| [4] | 陈美舟, 徐广飞, 王传旭, 等. 纵轴流辊式组合玉米柔性脱粒分离装置设计与试验[J]. 农业机械学报, 2020, 51(10): 123-131. |

| CHEN Meizhou, XU Guangfei, WANG Chuanxu, et al. Design and experiment of roller-type combined longitudinal axial flow flexible threshing and separating device for corn[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(10): 123-131. | |

| [5] | 苏媛, 刘浩, 徐杨, 等. 轴流式玉米脱粒装置钉齿元件优化与试验[J]. 农业机械学报, 2018, 49(S1): 258-265. |

| SU Yuan, LIU Hao, XU Yang, et al. Optimization and experiment of spike-tooth elements of axial flow corn threshing device[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(S1): 258-265. | |

| [6] |

崔中凯, 张华, 周进, 等. 智能玉米籽粒联合收获机设计与试验[J]. 中国农机化学报, 2019, 40(9): 26-30.

DOI |

| CUI Zhongkai, ZHANG Hua, ZHOU Jin, et al. Design and experiment of intelligent corn grain harvester[J]. Journal of Chinese Agricultural Mechanization, 2019, 40(9): 26-30. | |

| [7] | 李耀明, 唐忠, 徐立章, 等. 纵轴流脱粒分离装置功耗分析与试验[J]. 农业机械学报, 2011, 42(6): 93-97. |

| LI Yaoming, TANG Zhong, XU Lizhang, et al. Power analysis and experiment on longitudinal Axial-threshing unit test-bed[J]. Transactions of the Chinese Society for Agricultural Machinery, 2011, 42(6): 93-97. | |

| [8] | Srison W, Chuan-Udom S, Saengprachatanarug K. Design factors affecting losses and power consumption of an axial flow corn shelling unit[J]. Songklanakarin Journal of Science & Technology, 2016, 38(5): 591-598. |

| [9] | Keller D L, Converse H H, Hodges T O, et al. Corn kernel damage due to high velocity impact[J]. Transactions of the ASAE, 1972, 15(2): 330-332. |

| [10] | Burkhardt T H, Stout B A. Laboratory investigations of corn shelling utilizing high-velocity impact loading[J]. Transactions of the ASAE, 1974, 17(1): 11-14. |

| [11] | 王镇东, 崔涛, 张东兴, 等. 玉米收获机低损变径脱粒滚筒设计与试验[J]. 农业机械学报, 2021, 52(8): 98-105. |

| WANG Zhendong, CUI Tao, ZHANG Dongxing, et al. Design and experiment of low damage corn threshing drum with gradually changing diameter[J]. Transactions of the Chinese Society for Agricultural Machinery, 2021, 52(8): 98-105. | |

| [12] | 张莉, 林诚育, 侯国珍, 等. 高含水率玉米仿生脱粒元件设计与试验[J]. 农机化研究, 2021, 43(2): 126-131. |

| ZHANG Li, LIN Chengyu, HOU Guozhen, et al. Design and experiment of bionic threshing part for high moisture content corn[J]. Journal of Agricultural Mechanization Research, 2021, 43(2): 126-131. | |

| [13] | 樊晨龙, 崔涛, 张东兴, 等. 低损伤组合式玉米脱粒分离装置设计与试验[J]. 农业机械学报, 2019, 50(4): 113-123. |

| FAN Chenlong, CUI Tao, ZHANG Dongxing, et al. Design and test of low-damage combined corn threshing and separating device[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(4): 113-123. | |

| [14] | 廖庆喜, 徐阳, 袁佳诚, 等. 油菜联合收获机切抛组合式纵轴流脱离装置设计与试验[J]. 农业机械学报, 2019, 50(7): 140-150. |

| LIAO Qingxi, XU Yang, YUAN Jiacheng, et al. Design and experiment on combined cutting and throwing longitudinal axial flow threshing and separating device of rape combine harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(7): 140-150. | |

| [15] | 李海同, 万星宇, 王华, 等. 油菜联合收获机集成式纵轴流脱离装置设计与试验[J]. 农业机械学报, 2017, 48(5): 108-116. |

| LI Haitong, WAN Xingyu, WANG Hua, et al. Design and experiment on integrated longitudinal axial flow threshing and separating device of rape combine harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(5): 108-116. | |

| [16] | 中国农业机械化科学研究院. 农业机械设计手册: 下册[M]. 北京: 中国农业科学技术出版社, 2007. |

| Chinese Academy of Agricultural Mechanization Science. Agricultural machinery design Manual: Volume 2[M]. Beijing: China Agricultural Science and Technology Press, 2007. | |

| [17] | 张屹晨. 玉米籽粒收获机械单纵轴流脱粒滚筒设计与试验[D]. 长春: 吉林大学, 2020. |

| ZHANG Yichen. Design and Test of Single Axial Flow Threshing Drum for Corn Grain Harvester[D]. Changchun: Jilin University, 2020. | |

| [18] | 李科. 纵轴流玉米籽粒直收脱粒装置的设计与试验研究[D]. 泰安: 山东农业大学, 2021. |

| LI Ke. Design and Experimental Research on the Vertical Axial Flow Corn Seed Direct Harvest Threshing Device[D]. Taian: Shandong Agricultural University, 2021. | |

| [19] | 王占滨, 王振伟, 张银平, 等. 纵轴流柔性锤爪式玉米脱粒装置设计与试验[J]. 农业机械学报, 2020, 51(S2): 109-117. |

| WANG Zhanbin, WANG Zhenwei, ZHANG Yinping, et al. Design and test of longitudinal axial flexible hammer-claw corn thresher[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(S2): 109-117. | |

| [20] | 宋志才. 锥筒玉米柔性脱粒分离技术与装置研究[D]. 淄博: 山东理工大学, 2022. |

| SONG Zhicai. Research on Technology and Device of Conical Drum Flexible Threshing and Separation of Corn[D]. Zibo: Shandong University of Technology, 2022. | |

| [21] | 李心平, 王文哲, 赵高源, 等. 纵轴流双柔性碾搓式谷子脱粒装置设计与试验[J]. 农业机械学报, 2021, 52(7): 113-123. |

| LI Xinping, WANG Wenzhe, ZHAO Gaoyuan, et al. Design and experiment of longitudinal axial flow double flexible rolling and kneading threshing device for millet[J]. Transactions of the Chinese Society for Agricultural Machinery, 2021, 52(7): 113-123. | |

| [22] | 屈哲, 张东兴, 杨丽, 等. 纵轴流玉米脱粒分离装置喂入量与滚筒转速试验[J]. 农业机械学报, 2018, 49(2): 58-65. |

| QU Zhe, ZHANG Dongxing, YANG Li, et al. Experiment on feed rate and cylinder speed of longitudinal axial flow threshing and separating device for maize[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(2): 58-65. | |

| [23] | 谢干. 鼓形杆齿式纵轴流脱粒分离装置设计与试验研究[D]. 武汉: 华中农业大学, 2020. |

| XIE Gan. Design and Experimental Research of Drum-shaped Rod-tooth Longitudinal Axial Flow Threshing and Separating Device[D]. Wuhan: Huazhong Agricultural University, 2020. | |

| [24] | 许大兴, 杨健明. 卧式轴流脱粒分离装置研究[J]. 农业机械学报, 1984, 15(3): 57-66. |

| XU Daxing, YANG Jianming. Study of horizontal axial-flow thrash-separating unit characteristics[J]. Transactions of the Chinese Society of Agricultural Machinery, 1984, 15(3): 57-66. | |

| [25] | GB/T 21961—2008玉米收获机械试验方法[S]. |

| GB/T 21961—2008.Test methods for maize combine harvester[S]. | |

| [26] | GB/T 5982—2005. 脱粒机试验方法[S]. |

| GB/T 5982—2005. Testing method for thresher[S]. | |

| [27] | 邵永明. 玉米籽粒收获机低损伤脱粒装备设计与试验研究[D]. 滁州: 安徽科技学院, 2020. |

| SHAO Yongming. Design and experimental study of low-damage threshing equipment for corn grain harvester[D]. Chuzhou: Anhui University of Science and Technology, 2020. | |

| [28] | 王贺. 高含水率玉米单纵轴流板齿脱粒装置技术研究[D]. 长春: 吉林大学, 2022. |

| WANG He. Research on technology of single longitudinal axial flow plate tooth threshing device for maize with high moisture content[D]. Changchun: Jilin University, 2022. | |

| [29] | 耿端阳, 孙延成, 王宗源, 等. 玉米籽粒直收机板齿式脱粒装置设计与试验[J]. 吉林大学学报(工学版), 2023, 53(11): 3281-3292. |

| GENG Duanyang, SUN Yancheng, WANG Zongyuan, et al. Design and test of plate-toothed threshing device for corn grain direct harvester[J]. Journal of Jilin University(Engineering Science), 2023, 53(11): 3281-3292. | |

| [30] | 王永刚. 高含水率玉米籽粒脱粒装置设计与试验研究[D]. 淄博: 山东理工大学, 2019. |

| WANG Yonggang. Design and experimental study of maize grain threshing device with high moisture content[D]. Zibo: Shandong University of Technology, 2019. | |

| [31] | 王博. 玉米脱粒损伤机理及籽粒收获脱粒装置研究[D]. 杭州: 浙江大学, 2019. |

| WANG Bo. Study on damage mechanism of maize threshing and grain harvesting and threshing device[D]. Hangzhou: Zhejiang University, 2019. | |

| [32] | 何珂. 玉米柔性脱粒装置设计与试验[D]. 淄博: 山东理工大学, 2019. |

| HE Ke. Design and test of flexible threshing device for maize[D]. Zibo: Shandong University of Technology, 2019. |

| [1] | 郭文超, 贾尊尊, 丁新华, 叶晓琴, 付开赟, 吐尔逊·阿合买提, 王小武, 乔小燕, 孙建博. 新疆荒漠绿洲生态区亚洲玉米螟和欧洲玉米螟的种间竞争取代研究综述[J]. 新疆农业科学, 2024, 61(S1): 1-11. |

| [2] | 孙健博, 吴莉莉, 贾尊尊, 叶晓琴, 丁新华, 付开赟, 吐尔逊·阿合买提, 王哲, 李亚文, 付文君, 艾尔肯娜依·买买提江, 安尼瓦尔·库尔班, 郭文超. 新疆伊犁河谷玉米主要害虫田间一喷多防药效评价[J]. 新疆农业科学, 2024, 61(S1): 12-18. |

| [3] | 张帅, 高国文, 吴莉莉, 赵海燕, 王小武, 付开赟, 贾尊尊, 吐尔逊·阿合买提, 丁新华, 李克梅, 郭文超. 增效剂及微肥与种衣剂协同施用评价玉米茎腐病的防效[J]. 新疆农业科学, 2024, 61(S1): 19-27. |

| [4] | 戴爱梅, 叶梦迪, 丁志梅, 王志慧, 乔晓燕, 王小武, 付开赟, 贾尊尊, 叶晓琴, 吐尔逊·阿合买提, 康健, 丁新华, 郭文超. 不同苯唑氟草酮施药方式防除玉米田杂草药效及安全性评价[J]. 新疆农业科学, 2024, 61(S1): 28-34. |

| [5] | 袁梓涵, 赵雯慧, 王小武, 吐尔逊·阿合买提, 丁新华, 张帅, 付开赟, 贾尊尊, 郭文超. 玉米茎腐病生防菌的筛选及生防效果评价[J]. 新疆农业科学, 2024, 61(S1): 35-48. |

| [6] | 巩雪花, 王小武, 付开赟, 贾尊尊, 吐尔逊·阿合买提, 乔小燕, 叶晓琴, 郭文超, 丁新华. 新疆绿洲灌区玉米田杂草种子库及环境因子对杂草种子萌发的影响[J]. 新疆农业科学, 2024, 61(S1): 49-59. |

| [7] | 张磊, 孙诗仁, 谢小清, 王业建, 李冬, 唐怀君, 刘成. 额敏县玉米灌溉用水现状及节水灌溉策略[J]. 新疆农业科学, 2024, 61(S1): 81-84. |

| [8] | 杨明花, 廖必勇, 刘强, 彭云承, 达吾来·杰克山, 冯国瑞, 唐式敏. 鲜食糯玉米籽粒营养品质的差异变化分析[J]. 新疆农业科学, 2024, 61(9): 2087-2093. |

| [9] | 杨彩霞, 顾炜, 关媛, 瞿静涛, 党冬冬, 吴鹏昊, 郑洪建. 甜玉米基因Sugary1(Su1)序列的变异分析[J]. 新疆农业科学, 2024, 61(7): 1605-1614. |

| [10] | 钟辉丽, 武均, 陆祥生. 甜玉米不同生育期施用改良剂组合对其产量及河西走廊次生盐碱化土壤性质的影响[J]. 新疆农业科学, 2024, 61(7): 1615-1625. |

| [11] | 杨明花, 刘强, 冯国瑞, 廖必勇, 达吾来·杰克山, 彭云承, 布阿依夏木·那曼提, 陈艳萍. 鲜食糯玉米适宜采收期与籽粒含水量分析[J]. 新疆农业科学, 2024, 61(7): 1626-1630. |

| [12] | 付浩, 张学军, 史增录, 程金鹏, 吴海峰, 于永良, 饶志强. 滴灌区玉米精量免耕播种机设计与试验[J]. 新疆农业科学, 2024, 61(5): 1094-1101. |

| [13] | 刘婉琴, 易鸳鸯, 彭小武, 谢芳, 顾美英, 张志东. 头孢菌素菌渣有机肥对玉米土壤中耐药菌及相关抗性基因的影响[J]. 新疆农业科学, 2024, 61(4): 1003-1010. |

| [14] | 朱韬, 雷庆元, 马亮. 不同水氮用量对复播玉米生长发育、产量及利用效率的影响和选优模型验证[J]. 新疆农业科学, 2024, 61(4): 835-844. |

| [15] | 张磊, 姚梦瑶, 刘志刚, 李娟, 杨洋, 蔡大润, 陈果, 李波, 李晓荣, 陈勋基, 翟云龙. 基于无人机多光谱NDVI值估测玉米产量[J]. 新疆农业科学, 2024, 61(4): 845-851. |

| 阅读次数 | ||||||||||||||||||||||||||||||||||||||||||||||||||

|

全文 19

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

摘要 103

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||