Xinjiang Agricultural Sciences ›› 2024, Vol. 61 ›› Issue (10): 2500-2513.DOI: 10.6048/j.issn.1001-4330.2024.10.018

• Plant Protection · Soil Fertilizer · Water Saving Irrigation · Agricultural Equipment Engineering and Mechanization · Prataculture • Previous Articles Next Articles

XU Luming1( ), JIN Fan1,2(

), JIN Fan1,2( ), ZHANG Junsan1,2, Alimu Maimaitituerxun1,2, LI Qianxu2, SUN Lifeng2

), ZHANG Junsan1,2, Alimu Maimaitituerxun1,2, LI Qianxu2, SUN Lifeng2

Received:2024-03-28

Online:2024-10-20

Published:2024-11-07

Correspondence author:

JIN Fan

Supported by:

徐路明1( ), 靳范1,2(

), 靳范1,2( ), 张俊三1,2, 阿力木·买买提吐尔逊1,2, 李谦绪2, 孙利峰2

), 张俊三1,2, 阿力木·买买提吐尔逊1,2, 李谦绪2, 孙利峰2

通讯作者:

靳范

作者简介:徐路明(1997-),男,辽宁鞍山人,硕士研究生,研究方向为现代农业机械装备,(E-mail)1067029962@qq.com

基金资助:CLC Number:

XU Luming, JIN Fan, ZHANG Junsan, Alimu Maimaitituerxun, LI Qianxu, SUN Lifeng. Design and experiment of combined threshing and separating device for corn grain harvester[J]. Xinjiang Agricultural Sciences, 2024, 61(10): 2500-2513.

徐路明, 靳范, 张俊三, 阿力木·买买提吐尔逊, 李谦绪, 孙利峰. 玉米籽粒收获机喂抛组合式脱粒分离装置设计与试验[J]. 新疆农业科学, 2024, 61(10): 2500-2513.

| 参数 Argument | 数值 Numerical value |

|---|---|

| 行距 Line spacing (mm) | 550 |

| 株距 Spacing in rows (mm) | 350 |

| 自然株高 Natural plant height (mm) | 2 943 |

| 最低结穗高度 Minimum heading height (mm) | 1 315 |

| 百粒重 Hundred-grain weight (g) | 35.7 |

| 果穗长 Ear length (mm) | 220 |

| 籽粒含水率 Grain moisture content (%) | 25.2 |

Tab.1 Relevant parameters of corn plants and ears

| 参数 Argument | 数值 Numerical value |

|---|---|

| 行距 Line spacing (mm) | 550 |

| 株距 Spacing in rows (mm) | 350 |

| 自然株高 Natural plant height (mm) | 2 943 |

| 最低结穗高度 Minimum heading height (mm) | 1 315 |

| 百粒重 Hundred-grain weight (g) | 35.7 |

| 果穗长 Ear length (mm) | 220 |

| 籽粒含水率 Grain moisture content (%) | 25.2 |

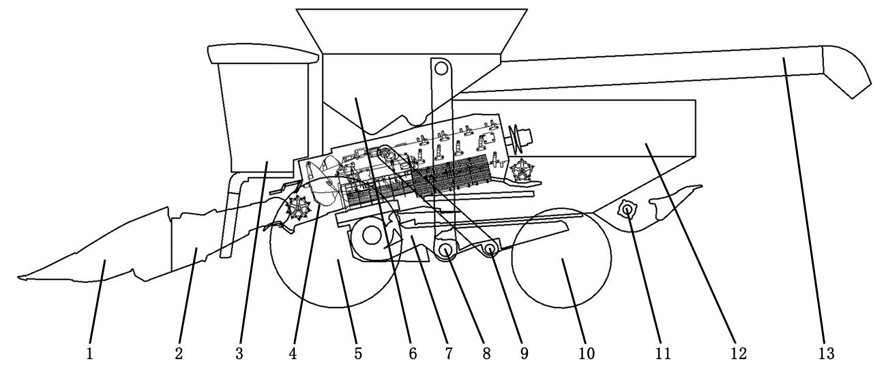

Fig.1 Structure diagram of 4YZL-13 self-propelled corn grain harvester Notes:1.Cutting table;2.Bridge;3.Cab;4.Feed and throw combined threshing separation device;5.Drive wheel;6.Granary;7.Cleaning system;8.Grain winch;9.Miscellaneous winch;10.Steering wheel;11.Chopper;12.Frame;13.Discharge cylinder

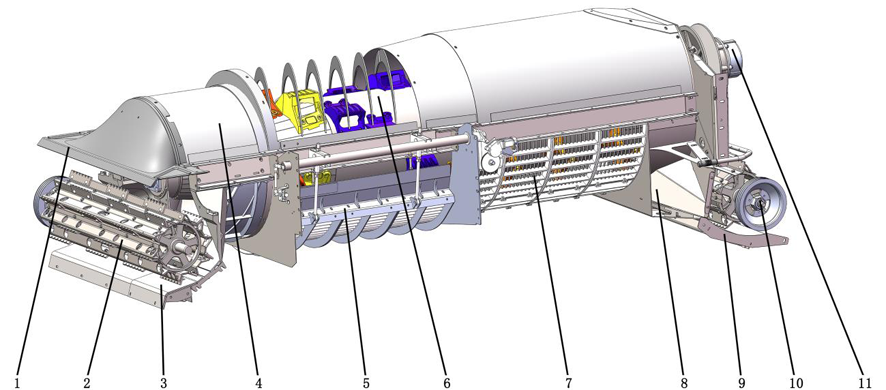

Fig.2 Structure diagram of feed and throw combined threshing and separating device Notes:1.Shield;2.Feed acceleration roller;3.Feed inlet;4.Guide hood;5.Threshing concave plate;6.Single longitudinal axial flow roller;7.Separation concave plate;8.Straw drain;9.Drain concave plate;10.Drain roller;11.Gearbox

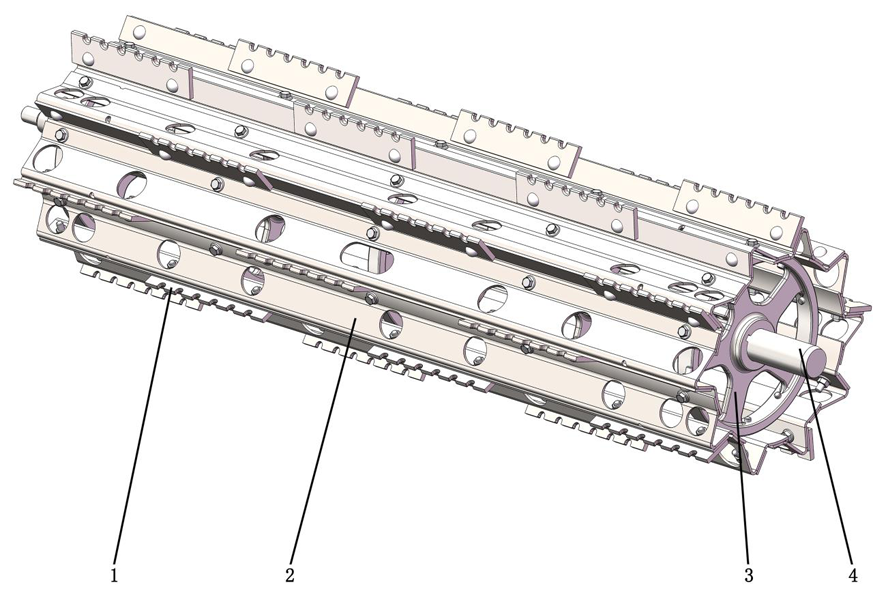

Fig.4 Structure diagram of feeding acceleration roller Notes:1.Wear-resistant gear plate;2.Mounting plate;3.Supporting wheel hub;4.Feeding acceleration roller

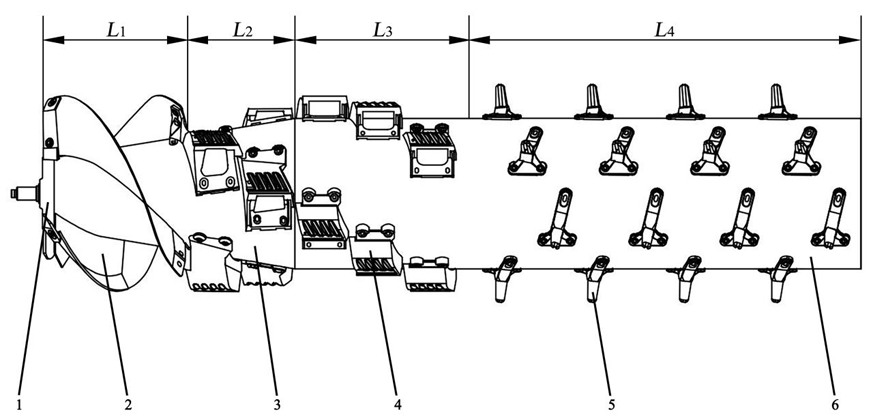

Fig.6 Single longitudinal axial flow drum structure diagram Notes:1.Connecting shaft;2.Spiral blade;3.Cone;4.Threshing rod;5.Separation nail teeth;6.Straight barrel

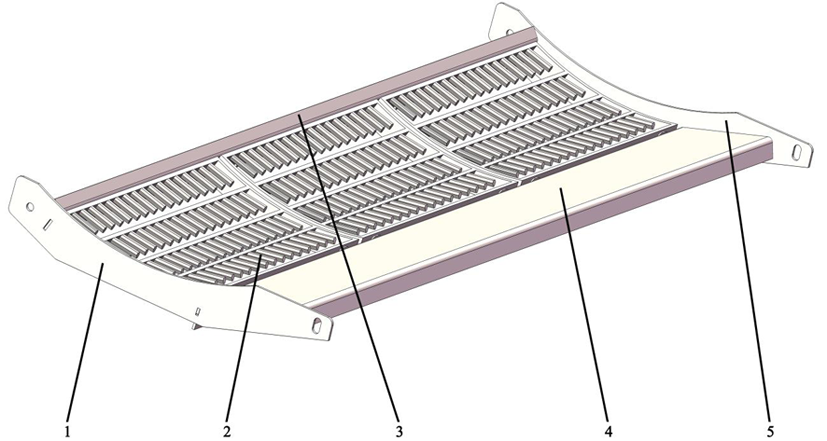

Fig.10 The structure diagram of thegrass concave plate Notes:1.Left panel;2.Semi-grid concave panel;3.Rear mounting panel;4.Front mounting panel;5.Right-side plate

| 编码 Coding | 滚筒转速A Drum speed A (r/min) | 凹板间隙B Concave clearance B (mm) | 喂入量C Feed amount C (kg/s) |

|---|---|---|---|

| -1 | 400 | 30 | 16 |

| 0 | 450 | 35 | 17 |

| 1 | 500 | 40 | 18 |

Tab.2 Test factor coding

| 编码 Coding | 滚筒转速A Drum speed A (r/min) | 凹板间隙B Concave clearance B (mm) | 喂入量C Feed amount C (kg/s) |

|---|---|---|---|

| -1 | 400 | 30 | 16 |

| 0 | 450 | 35 | 17 |

| 1 | 500 | 40 | 18 |

| 序号 Number | 试验因素 Experimental factor | 评价指标 Evaluation index | |||

|---|---|---|---|---|---|

| 滚筒转速A Drum speed A (r/min) | 凹板间隙B Concave clearance B (mm) | 喂入量C Feed amount C (kg/s) | 籽粒破碎率Zs Grain breakage rate Zs (%) | 未脱净率Sw Unstripped rate Sw (%) | |

| 1 | -1 | -1 | 0 | 3.25 | 2.05 |

| 2 | 1 | -1 | 0 | 4.18 | 0.97 |

| 3 | -1 | 1 | 0 | 2.55 | 2.07 |

| 4 | 1 | 1 | 0 | 3.61 | 1.93 |

| 5 | -1 | 0 | -1 | 2.43 | 1.61 |

| 6 | 1 | 0 | -1 | 3.72 | 0.75 |

| 7 | -1 | 0 | 1 | 3.51 | 2.06 |

| 8 | 1 | 0 | 1 | 4.19 | 1.35 |

| 9 | 0 | -1 | -1 | 3.21 | 1.08 |

| 10 | 0 | 1 | -1 | 2.41 | 1.91 |

| 11 | 0 | -1 | 1 | 3.85 | 1.71 |

| 12 | 0 | 1 | 1 | 3.92 | 1.89 |

| 13 | 0 | 0 | 0 | 2.98 | 1.16 |

| 14 | 0 | 0 | 0 | 2.83 | 0.98 |

| 15 | 0 | 0 | 0 | 2.94 | 1.11 |

| 16 | 0 | 0 | 0 | 2.96 | 1.13 |

| 17 | 0 | 0 | 0 | 2.81 | 0.95 |

Tab.3 Experimental scheme and results

| 序号 Number | 试验因素 Experimental factor | 评价指标 Evaluation index | |||

|---|---|---|---|---|---|

| 滚筒转速A Drum speed A (r/min) | 凹板间隙B Concave clearance B (mm) | 喂入量C Feed amount C (kg/s) | 籽粒破碎率Zs Grain breakage rate Zs (%) | 未脱净率Sw Unstripped rate Sw (%) | |

| 1 | -1 | -1 | 0 | 3.25 | 2.05 |

| 2 | 1 | -1 | 0 | 4.18 | 0.97 |

| 3 | -1 | 1 | 0 | 2.55 | 2.07 |

| 4 | 1 | 1 | 0 | 3.61 | 1.93 |

| 5 | -1 | 0 | -1 | 2.43 | 1.61 |

| 6 | 1 | 0 | -1 | 3.72 | 0.75 |

| 7 | -1 | 0 | 1 | 3.51 | 2.06 |

| 8 | 1 | 0 | 1 | 4.19 | 1.35 |

| 9 | 0 | -1 | -1 | 3.21 | 1.08 |

| 10 | 0 | 1 | -1 | 2.41 | 1.91 |

| 11 | 0 | -1 | 1 | 3.85 | 1.71 |

| 12 | 0 | 1 | 1 | 3.92 | 1.89 |

| 13 | 0 | 0 | 0 | 2.98 | 1.16 |

| 14 | 0 | 0 | 0 | 2.83 | 0.98 |

| 15 | 0 | 0 | 0 | 2.94 | 1.11 |

| 16 | 0 | 0 | 0 | 2.96 | 1.13 |

| 17 | 0 | 0 | 0 | 2.81 | 0.95 |

| 方差来源 Source of variation | 籽粒破碎率Zs Grain breakage rate Zs (%) | 未脱净率Sw Unstripped rate Sw (%) | ||

|---|---|---|---|---|

| F值 F-value | P | F值 F-value | P | |

| 回归模型Regression model | 39.33 | <0.000 1** | 35.20 | <0.000 1** |

| A | 129.42 | <0.000 1** | 90.40 | <0.000 1** |

| B | 33.01 | 0.000 7** | 45.99 | 0.000 3** |

| C | 112.99 | <0.000 1** | 32.00 | 0.000 8** |

| AB | 0.279 0 | 0.613 7 | 20.52 | 0.002 7** |

| AC | 6.14 | 0.042 3* | 0.522 6 | 0.493 2 |

| BC | 12.49 | 0.009 5** | 9.81 | 0.016 5* |

| A2 | 25.73 | 0.001 4** | 22.91 | 0.002 0** |

| B2 | 9.96 | 0.016 0* | 78.16 | <0.000 1** |

| C2 | 17.97 | 0.003 8** | 7.08 | 0.032 5* |

| 失拟项 Loss of quasi item | 4.43 | 0.092 2 | 1.48 | 0.347 4 |

Tab.4 Changes of variance of grain crushing rate Zs and unstripped rate Sw

| 方差来源 Source of variation | 籽粒破碎率Zs Grain breakage rate Zs (%) | 未脱净率Sw Unstripped rate Sw (%) | ||

|---|---|---|---|---|

| F值 F-value | P | F值 F-value | P | |

| 回归模型Regression model | 39.33 | <0.000 1** | 35.20 | <0.000 1** |

| A | 129.42 | <0.000 1** | 90.40 | <0.000 1** |

| B | 33.01 | 0.000 7** | 45.99 | 0.000 3** |

| C | 112.99 | <0.000 1** | 32.00 | 0.000 8** |

| AB | 0.279 0 | 0.613 7 | 20.52 | 0.002 7** |

| AC | 6.14 | 0.042 3* | 0.522 6 | 0.493 2 |

| BC | 12.49 | 0.009 5** | 9.81 | 0.016 5* |

| A2 | 25.73 | 0.001 4** | 22.91 | 0.002 0** |

| B2 | 9.96 | 0.016 0* | 78.16 | <0.000 1** |

| C2 | 17.97 | 0.003 8** | 7.08 | 0.032 5* |

| 失拟项 Loss of quasi item | 4.43 | 0.092 2 | 1.48 | 0.347 4 |

| 序号 Number | 籽粒破碎率Zs Grain breakage rate Zs (%) | 未脱净率Sw Unstripped rate Sw (%) |

|---|---|---|

| 1 | 2.69 | 1.01 |

| 2 | 2.74 | 1.03 |

| 3 | 2.76 | 1.08 |

| 均值 Mean value | 2.73 | 1.04 |

Tab.5 Experimental results after parameter optimization

| 序号 Number | 籽粒破碎率Zs Grain breakage rate Zs (%) | 未脱净率Sw Unstripped rate Sw (%) |

|---|---|---|

| 1 | 2.69 | 1.01 |

| 2 | 2.74 | 1.03 |

| 3 | 2.76 | 1.08 |

| 均值 Mean value | 2.73 | 1.04 |

| [1] | 耿爱军, 杨建宁, 张兆磊, 等. 国内外玉米收获机械发展现状及展望[J]. 农机化研究, 2016, 38(4): 251-257. |

| GENG Aijun, YANG Jianning, ZHANG Zhaolei, et al. Discuss about the current situation and future of corn harvest machinery about domestic and abroad[J]. Journal of Agricultural Mechanization Research, 2016, 38(4): 251-257. | |

| [2] | 耿端阳, 何珂, 王骞, 等. 横轴流式玉米柔性脱粒装置设计与试验[J]. 农业机械学报, 2019, 50(3): 101-108. |

| GENG Duanyang, HE Ke, WANG Qian, et al. Design and experiment on transverse axial flow flexible threshing device for corn[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(3): 101-108. | |

| [3] | 崔涛, 樊晨龙, 张东兴, 等. 玉米机械化收获技术研究进展分析[J]. 农业机械学报, 2019, 50(12): 1-13. |

| CUI Tao, FAN Chenlong, ZHANG Dongxing, et al. Research progress of maize mechanized harvesting technology[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(12): 1-13. | |

| [4] | 陈美舟, 徐广飞, 王传旭, 等. 纵轴流辊式组合玉米柔性脱粒分离装置设计与试验[J]. 农业机械学报, 2020, 51(10): 123-131. |

| CHEN Meizhou, XU Guangfei, WANG Chuanxu, et al. Design and experiment of roller-type combined longitudinal axial flow flexible threshing and separating device for corn[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(10): 123-131. | |

| [5] | 苏媛, 刘浩, 徐杨, 等. 轴流式玉米脱粒装置钉齿元件优化与试验[J]. 农业机械学报, 2018, 49(S1): 258-265. |

| SU Yuan, LIU Hao, XU Yang, et al. Optimization and experiment of spike-tooth elements of axial flow corn threshing device[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(S1): 258-265. | |

| [6] |

崔中凯, 张华, 周进, 等. 智能玉米籽粒联合收获机设计与试验[J]. 中国农机化学报, 2019, 40(9): 26-30.

DOI |

| CUI Zhongkai, ZHANG Hua, ZHOU Jin, et al. Design and experiment of intelligent corn grain harvester[J]. Journal of Chinese Agricultural Mechanization, 2019, 40(9): 26-30. | |

| [7] | 李耀明, 唐忠, 徐立章, 等. 纵轴流脱粒分离装置功耗分析与试验[J]. 农业机械学报, 2011, 42(6): 93-97. |

| LI Yaoming, TANG Zhong, XU Lizhang, et al. Power analysis and experiment on longitudinal Axial-threshing unit test-bed[J]. Transactions of the Chinese Society for Agricultural Machinery, 2011, 42(6): 93-97. | |

| [8] | Srison W, Chuan-Udom S, Saengprachatanarug K. Design factors affecting losses and power consumption of an axial flow corn shelling unit[J]. Songklanakarin Journal of Science & Technology, 2016, 38(5): 591-598. |

| [9] | Keller D L, Converse H H, Hodges T O, et al. Corn kernel damage due to high velocity impact[J]. Transactions of the ASAE, 1972, 15(2): 330-332. |

| [10] | Burkhardt T H, Stout B A. Laboratory investigations of corn shelling utilizing high-velocity impact loading[J]. Transactions of the ASAE, 1974, 17(1): 11-14. |

| [11] | 王镇东, 崔涛, 张东兴, 等. 玉米收获机低损变径脱粒滚筒设计与试验[J]. 农业机械学报, 2021, 52(8): 98-105. |

| WANG Zhendong, CUI Tao, ZHANG Dongxing, et al. Design and experiment of low damage corn threshing drum with gradually changing diameter[J]. Transactions of the Chinese Society for Agricultural Machinery, 2021, 52(8): 98-105. | |

| [12] | 张莉, 林诚育, 侯国珍, 等. 高含水率玉米仿生脱粒元件设计与试验[J]. 农机化研究, 2021, 43(2): 126-131. |

| ZHANG Li, LIN Chengyu, HOU Guozhen, et al. Design and experiment of bionic threshing part for high moisture content corn[J]. Journal of Agricultural Mechanization Research, 2021, 43(2): 126-131. | |

| [13] | 樊晨龙, 崔涛, 张东兴, 等. 低损伤组合式玉米脱粒分离装置设计与试验[J]. 农业机械学报, 2019, 50(4): 113-123. |

| FAN Chenlong, CUI Tao, ZHANG Dongxing, et al. Design and test of low-damage combined corn threshing and separating device[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(4): 113-123. | |

| [14] | 廖庆喜, 徐阳, 袁佳诚, 等. 油菜联合收获机切抛组合式纵轴流脱离装置设计与试验[J]. 农业机械学报, 2019, 50(7): 140-150. |

| LIAO Qingxi, XU Yang, YUAN Jiacheng, et al. Design and experiment on combined cutting and throwing longitudinal axial flow threshing and separating device of rape combine harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(7): 140-150. | |

| [15] | 李海同, 万星宇, 王华, 等. 油菜联合收获机集成式纵轴流脱离装置设计与试验[J]. 农业机械学报, 2017, 48(5): 108-116. |

| LI Haitong, WAN Xingyu, WANG Hua, et al. Design and experiment on integrated longitudinal axial flow threshing and separating device of rape combine harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(5): 108-116. | |

| [16] | 中国农业机械化科学研究院. 农业机械设计手册: 下册[M]. 北京: 中国农业科学技术出版社, 2007. |

| Chinese Academy of Agricultural Mechanization Science. Agricultural machinery design Manual: Volume 2[M]. Beijing: China Agricultural Science and Technology Press, 2007. | |

| [17] | 张屹晨. 玉米籽粒收获机械单纵轴流脱粒滚筒设计与试验[D]. 长春: 吉林大学, 2020. |

| ZHANG Yichen. Design and Test of Single Axial Flow Threshing Drum for Corn Grain Harvester[D]. Changchun: Jilin University, 2020. | |

| [18] | 李科. 纵轴流玉米籽粒直收脱粒装置的设计与试验研究[D]. 泰安: 山东农业大学, 2021. |

| LI Ke. Design and Experimental Research on the Vertical Axial Flow Corn Seed Direct Harvest Threshing Device[D]. Taian: Shandong Agricultural University, 2021. | |

| [19] | 王占滨, 王振伟, 张银平, 等. 纵轴流柔性锤爪式玉米脱粒装置设计与试验[J]. 农业机械学报, 2020, 51(S2): 109-117. |

| WANG Zhanbin, WANG Zhenwei, ZHANG Yinping, et al. Design and test of longitudinal axial flexible hammer-claw corn thresher[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(S2): 109-117. | |

| [20] | 宋志才. 锥筒玉米柔性脱粒分离技术与装置研究[D]. 淄博: 山东理工大学, 2022. |

| SONG Zhicai. Research on Technology and Device of Conical Drum Flexible Threshing and Separation of Corn[D]. Zibo: Shandong University of Technology, 2022. | |

| [21] | 李心平, 王文哲, 赵高源, 等. 纵轴流双柔性碾搓式谷子脱粒装置设计与试验[J]. 农业机械学报, 2021, 52(7): 113-123. |

| LI Xinping, WANG Wenzhe, ZHAO Gaoyuan, et al. Design and experiment of longitudinal axial flow double flexible rolling and kneading threshing device for millet[J]. Transactions of the Chinese Society for Agricultural Machinery, 2021, 52(7): 113-123. | |

| [22] | 屈哲, 张东兴, 杨丽, 等. 纵轴流玉米脱粒分离装置喂入量与滚筒转速试验[J]. 农业机械学报, 2018, 49(2): 58-65. |

| QU Zhe, ZHANG Dongxing, YANG Li, et al. Experiment on feed rate and cylinder speed of longitudinal axial flow threshing and separating device for maize[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(2): 58-65. | |

| [23] | 谢干. 鼓形杆齿式纵轴流脱粒分离装置设计与试验研究[D]. 武汉: 华中农业大学, 2020. |

| XIE Gan. Design and Experimental Research of Drum-shaped Rod-tooth Longitudinal Axial Flow Threshing and Separating Device[D]. Wuhan: Huazhong Agricultural University, 2020. | |

| [24] | 许大兴, 杨健明. 卧式轴流脱粒分离装置研究[J]. 农业机械学报, 1984, 15(3): 57-66. |

| XU Daxing, YANG Jianming. Study of horizontal axial-flow thrash-separating unit characteristics[J]. Transactions of the Chinese Society of Agricultural Machinery, 1984, 15(3): 57-66. | |

| [25] | GB/T 21961—2008玉米收获机械试验方法[S]. |

| GB/T 21961—2008.Test methods for maize combine harvester[S]. | |

| [26] | GB/T 5982—2005. 脱粒机试验方法[S]. |

| GB/T 5982—2005. Testing method for thresher[S]. | |

| [27] | 邵永明. 玉米籽粒收获机低损伤脱粒装备设计与试验研究[D]. 滁州: 安徽科技学院, 2020. |

| SHAO Yongming. Design and experimental study of low-damage threshing equipment for corn grain harvester[D]. Chuzhou: Anhui University of Science and Technology, 2020. | |

| [28] | 王贺. 高含水率玉米单纵轴流板齿脱粒装置技术研究[D]. 长春: 吉林大学, 2022. |

| WANG He. Research on technology of single longitudinal axial flow plate tooth threshing device for maize with high moisture content[D]. Changchun: Jilin University, 2022. | |

| [29] | 耿端阳, 孙延成, 王宗源, 等. 玉米籽粒直收机板齿式脱粒装置设计与试验[J]. 吉林大学学报(工学版), 2023, 53(11): 3281-3292. |

| GENG Duanyang, SUN Yancheng, WANG Zongyuan, et al. Design and test of plate-toothed threshing device for corn grain direct harvester[J]. Journal of Jilin University(Engineering Science), 2023, 53(11): 3281-3292. | |

| [30] | 王永刚. 高含水率玉米籽粒脱粒装置设计与试验研究[D]. 淄博: 山东理工大学, 2019. |

| WANG Yonggang. Design and experimental study of maize grain threshing device with high moisture content[D]. Zibo: Shandong University of Technology, 2019. | |

| [31] | 王博. 玉米脱粒损伤机理及籽粒收获脱粒装置研究[D]. 杭州: 浙江大学, 2019. |

| WANG Bo. Study on damage mechanism of maize threshing and grain harvesting and threshing device[D]. Hangzhou: Zhejiang University, 2019. | |

| [32] | 何珂. 玉米柔性脱粒装置设计与试验[D]. 淄博: 山东理工大学, 2019. |

| HE Ke. Design and test of flexible threshing device for maize[D]. Zibo: Shandong University of Technology, 2019. |

| [1] | ZHANG Shuai, GAO Guowen, WU Lili, ZHAO Haiyan, WANG Xiaowu, FU Kaiyun, JIA Zunzun, Tuerxun Ahemaiti, DING Xinhua, LI Kemei, GUO Wenchao. Evaluation of the synergistic application of seed coating agents, synergists, and micro fertilizers for the prevention and control of corn stem rot disease [J]. Xinjiang Agricultural Sciences, 2024, 61(S1): 19-27. |

| [2] | DAI Aimei, YE Mengdi, DING Zhimei, WANG Zhihui, QIAO Xiaoyan, WANG Xiaowu, FU Kaiyun, JIA Zunzun, YE Xiaoqin, Tuerxun Ahemati, KANG Jian, DING Xinhua, GUO Wenchao. Evaluation on the efficacy and safety of dif ferent application methods of flumioxazinone in controlling weeds in corn field [J]. Xinjiang Agricultural Sciences, 2024, 61(S1): 28-34. |

| [3] | YUAN Zihan, ZHAO Wenhui, WANG Xiaowu, Tuerxun Ahemaiti, DING Xinhua, ZHANG Shuai, FU Kaiyun, JIA Zunzun, GUO Wenchao. Screening of Corn Stalk Rot control bacteria and evaluation of control effects [J]. Xinjiang Agricultural Sciences, 2024, 61(S1): 35-48. |

| [4] | GONG Xuehua, WANG Xiaowu, FU Kaiyun, JIA Zunzun, TURSUN Ahmat, QIAO Xiaoyan, YE Xiaoqin, GUO Wenchao, DING Xinhua. Effects of weed seeds bank and environmental factors on weed seeds germination in oasis irrigation areas of Xinjiang [J]. Xinjiang Agricultural Sciences, 2024, 61(S1): 49-59. |

| [5] | ZHANG Lei, SUN Shiren, XIE Xiaoqing, WANG Yejian, LI Dong, TANG Huaijun, LIU Cheng. Present situation of maize irrigation water and scientific water-saving irrigation strategy in Emin County [J]. Xinjiang Agricultural Sciences, 2024, 61(S1): 81-84. |

| [6] | YANG Minghua, LIAO Biyong, LIU Qiang, PENG Yuncheng, Dawulai Jiekeshan, FENG Guorui, TANG Shimin. Study on variation of grain nutritional quality of glutinous maize [J]. Xinjiang Agricultural Sciences, 2024, 61(9): 2087-2093. |

| [7] | YANG Caixia, GU Wei, GUAN Yuan, QU Jingtao, DANG Dongdong, WU Penghao, ZHENG Hongjian. Variation analysis of sweetness gene Sugary1 (Su1) sequence in Sweet corn [J]. Xinjiang Agricultural Sciences, 2024, 61(7): 1605-1614. |

| [8] | ZHONG Huili, WU Jun, LU Xiangsheng. Effects of different growth stage application combinations of amendments on secondary salinized soil properties and sweet corn yield in Hexi Corrido [J]. Xinjiang Agricultural Sciences, 2024, 61(7): 1615-1625. |

| [9] | FU Hao, ZHANG Xuejun, SHI Zenglu, CHENG Jinpeng, WU Haifeng, YU Yongliang, RAO Zhiqiang. Design and experiment of corn precision no-till planter in drip irrigation area [J]. Xinjiang Agricultural Sciences, 2024, 61(5): 1094-1101. |

| [10] | LIU Wanqin, YI Yuanyang, PENG Xiaowu, XIE Fang, GU Meiying, ZHANG Zhidong. Effect of cephalosporin residue organic fertilizer on resistant bacteria and related resistance genes in maize soil [J]. Xinjiang Agricultural Sciences, 2024, 61(4): 1003-1010. |

| [11] | ZHU Tao, Lei Qingyuan, MA Liang. Effects of water and nitrogen on growth, yield and water and nitrogen utilization efficiency of resown Maize and verification of scheme optimization model [J]. Xinjiang Agricultural Sciences, 2024, 61(4): 835-844. |

| [12] | FU Yanbo, BIAN Qingyong, WEI Yayuan, WEI Yanhong, ZHANG Wanxu, ZHU Jinquan. Effects of formula fertilizer on physiological growth and yield of drip irrigation maize [J]. Xinjiang Agricultural Sciences, 2024, 61(4): 878-884. |

| [13] | YANG Minghua, LIAO Biyong, LIU Qiang, FENG Guorui, Dawulai Jiekeshan, Buayixiamu Namanti, LIU Qi, Aierjuma Tuluhan, PENG Yuncheng. Comprehensive evaluation of dehydration of maize hybrid combinations based on principal component analysis [J]. Xinjiang Agricultural Sciences, 2024, 61(2): 318-325. |

| [14] | WANG Shanbo, Alimu Maimaitituerxun, LI Qianxu, DU Zhigao, ZHANG Wei. Design of and experiment on fresh corn flexible picking and damage-free collectting harvest header [J]. Xinjiang Agricultural Sciences, 2024, 61(1): 217-229. |

| [15] | WANG Ting, ZHANG Li, ZHANG Fanfan, HUANG Rongzheng, LI Xiao, ZHANG Yulin, CHEN Yongcheng, ZHAO Jiantao, MA Chunhui. Poduction performance screening and nutritional value evaluation of corn varieties suitable for silage [J]. Xinjiang Agricultural Sciences, 2023, 60(7): 1596-1605. |

| Viewed | ||||||||||||||||||||||||||||||||||||||||||||||||||

|

Full text 18

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Abstract 91

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||