Xinjiang Agricultural Sciences ›› 2023, Vol. 60 ›› Issue (12): 3102-3112.DOI: 10.6048/j.issn.1001-4330.2023.12.028

• Animal Husbandry Veterinarian·Microbes·Agricultural Equipment Engineering and Mechanization • Previous Articles Next Articles

ZHANG Wei1( ), JIN Fan1,2(

), JIN Fan1,2( ), LI Qianxu2, ZHANG Junsan2, ZHAI Xiuping2, WANG Shanbo1

), LI Qianxu2, ZHANG Junsan2, ZHAI Xiuping2, WANG Shanbo1

Received:2023-04-27

Online:2023-12-20

Published:2024-01-03

Correspondence author:

JIN Fan (1968-), male, from Urumqi, senior engineer with improved salary, bachelor degree,Resticide direction:agricultural machinery engineering,(E-mail)Supported by:

张伟1( ), 靳范1,2(

), 靳范1,2( ), 李谦绪2, 张俊三2, 翟修萍2, 王善博1

), 李谦绪2, 张俊三2, 翟修萍2, 王善博1

通讯作者:

靳范(1968-),男,新疆乌鲁木齐人,提高待遇高级工程师,硕士生导师,研究方向为农业机械装备工程,(E-mail)639916709@qq.com

作者简介:张伟(1997-),男,陕西安康人,硕士研究生,研究方向为农业机械装备,(E-mail)1213869102@qq.com

基金资助:CLC Number:

ZHANG Wei, JIN Fan, LI Qianxu, ZHANG Junsan, ZHAI Xiuping, WANG Shanbo. Design and experiment of cleaning device for corn grain combine harvester[J]. Xinjiang Agricultural Sciences, 2023, 60(12): 3102-3112.

张伟, 靳范, 李谦绪, 张俊三, 翟修萍, 王善博. 玉米籽粒联合收获机清选装置优化设计与试验[J]. 新疆农业科学, 2023, 60(12): 3102-3112.

Add to citation manager EndNote|Ris|BibTeX

URL: https://www.xjnykx.com/EN/10.6048/j.issn.1001-4330.2023.12.028

| 项目 Item | 参数 Parameters |

|---|---|

| 试验品种 Test varieties | 九圣禾2468 |

| 作物产量 Crop yield(g/m2) | 1 884.1 |

| 百粒质量 Hundred grain quality(g) | 53.1 |

| 作物自然高度 Natural height of the crop (mm) | 2712 |

| 株距 Plant spacing (mm) | 214 |

| 行距 Row spacing (mm) | 466 |

| 单穗籽粒质量 Seed mass per ear (g) | 176.7 |

| 单株果穗质量 Ear weight per plant (g) | 561.2 |

| 最低结穗高度 Minimum spike height (mm) | 1 099 |

| 籽粒含水率 Seed moisture content(%) | 26.88 |

Tab.1 Field test conditions

| 项目 Item | 参数 Parameters |

|---|---|

| 试验品种 Test varieties | 九圣禾2468 |

| 作物产量 Crop yield(g/m2) | 1 884.1 |

| 百粒质量 Hundred grain quality(g) | 53.1 |

| 作物自然高度 Natural height of the crop (mm) | 2712 |

| 株距 Plant spacing (mm) | 214 |

| 行距 Row spacing (mm) | 466 |

| 单穗籽粒质量 Seed mass per ear (g) | 176.7 |

| 单株果穗质量 Ear weight per plant (g) | 561.2 |

| 最低结穗高度 Minimum spike height (mm) | 1 099 |

| 籽粒含水率 Seed moisture content(%) | 26.88 |

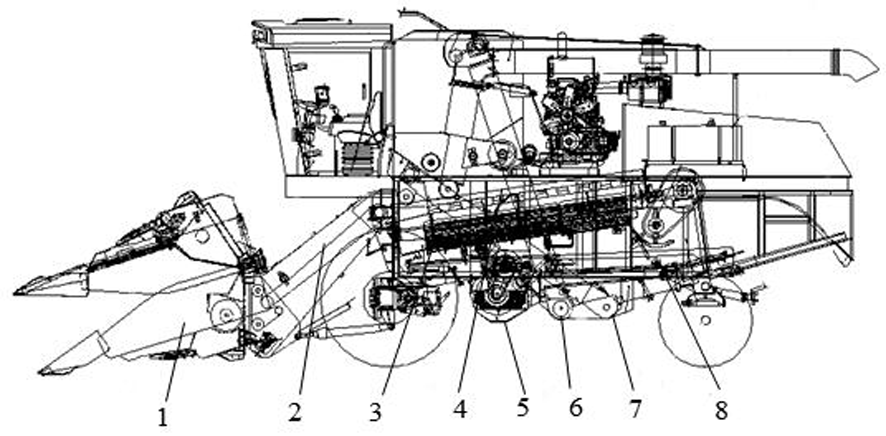

Fig.1 Structure diagram of corn combine harvester Note:1.Folding header;2.Bridge;3.Axial flow drum;4.Concave plate;5.Fan;6.Grain auger;7.Miscellaneous auger;8.Cleaning screen

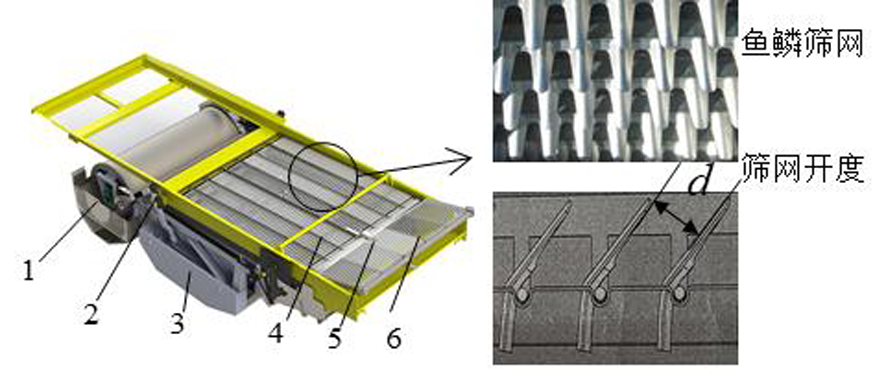

Fig.2 Structure diagram of corn kernel cleaning device Note:1.Fan;2.Crank connecting rod;3.Grain collection box;4.Fish scale upper screen;5.Fish scale screen adjusting handle;6.Tail screen

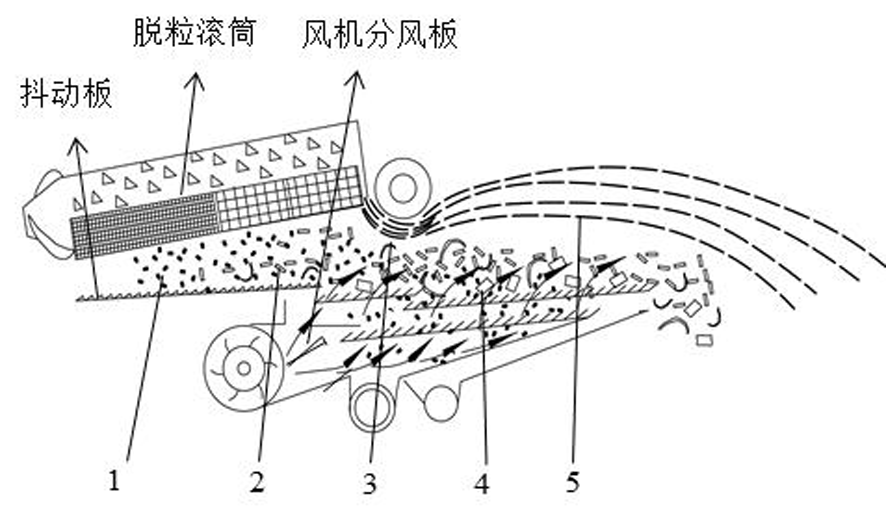

Fig.3 Schematic diagram of cleaning and separation operations Note:1.corn kernels;2.broken stalks;3.corn stalks and leaves;4.broken corn cobs;5.mixed impurities of stalks and cobs

| 优化方案 Optimised solutions | 蜗壳出口 扩张角θ Worm shell outlet expansion angleθ(°) | 蜗舌半径r Snail tongue radius r (mm) |

|---|---|---|

| 优化前 Before optimization | 25 | 15 |

| 优化后 After optimisation | 35 | 6 |

Tab.2 Comparison of parameters before and after volute optimization

| 优化方案 Optimised solutions | 蜗壳出口 扩张角θ Worm shell outlet expansion angleθ(°) | 蜗舌半径r Snail tongue radius r (mm) |

|---|---|---|

| 优化前 Before optimization | 25 | 15 |

| 优化后 After optimisation | 35 | 6 |

| 风机转速 Fan speed (r/min) | 优化前风量 Airflow before optimisation (m3/h) | 优化后风量 Optimised airflow (m3/h) | 效率提升 Efficiency gains (%) |

|---|---|---|---|

| 850 | 5 568 | 6 016 | 8 |

| 1 040 | 6 122 | 6 568 | 7.3 |

| 1 130 | 6 676 | 7 136 | 6.9 |

Tab.3 Air volume test before and after fan volute optimization

| 风机转速 Fan speed (r/min) | 优化前风量 Airflow before optimisation (m3/h) | 优化后风量 Optimised airflow (m3/h) | 效率提升 Efficiency gains (%) |

|---|---|---|---|

| 850 | 5 568 | 6 016 | 8 |

| 1 040 | 6 122 | 6 568 | 7.3 |

| 1 130 | 6 676 | 7 136 | 6.9 |

| 编码 Coding | 风机转速 Fan speed (r/min) | 振动频率 Vibration frequency (HZ) | 筛网开度 Screen opening (mm) |

|---|---|---|---|

| 1 | 1 200 | 8 | 22 |

| 0 | 1 050 | 6 | 16 |

| -1 | 900 | 4 | 10 |

Tab.4 Coding of experimental factors

| 编码 Coding | 风机转速 Fan speed (r/min) | 振动频率 Vibration frequency (HZ) | 筛网开度 Screen opening (mm) |

|---|---|---|---|

| 1 | 1 200 | 8 | 22 |

| 0 | 1 050 | 6 | 16 |

| -1 | 900 | 4 | 10 |

| 序号 Serial number | 风机转速 Fan speed A | 振动频率 Vibration frequency B | 筛网开度 Screen opening C | 籽粒 含杂率 Seed trash content T1(%) | 清选 损失率 Clearance loss rate T1(%) |

|---|---|---|---|---|---|

| 1 | 0 | 0 | 0 | 1.39 | 0.91 |

| 2 | -1 | -1 | 0 | 1.62 | 1.65 |

| 3 | 0 | -1 | 1 | 1.54 | 2.17 |

| 4 | 0 | 0 | 0 | 0.9 | 1.35 |

| 5 | 0 | 0 | 0 | 1.24 | 0.86 |

| 6 | 0 | 0 | 0 | 0.72 | 1.02 |

| 7 | 1 | 0 | 1 | 0.49 | 2.84 |

| 8 | 0 | 1 | 1 | 1.59 | 1.53 |

| 9 | 1 | 0 | -1 | 0.77 | 1.72 |

| 10 | 1 | 1 | 0 | 1.4 | 2.16 |

| 11 | 0 | 1 | -1 | 3.24 | 1.38 |

| 12 | 1 | -1 | 0 | 0.4 | 3.4 |

| 13 | -1 | 1 | 0 | 2.13 | 2.36 |

| 14 | -1 | 0 | 1 | 1.92 | 1.18 |

| 15 | -1 | 0 | -1 | 2.69 | 1.57 |

| 16 | 0 | -1 | -1 | 2.39 | 1.74 |

| 17 | 0 | 0 | 0 | 1.01 | 1.09 |

Tab.5 Test scheme and results of corn grain cleaning device

| 序号 Serial number | 风机转速 Fan speed A | 振动频率 Vibration frequency B | 筛网开度 Screen opening C | 籽粒 含杂率 Seed trash content T1(%) | 清选 损失率 Clearance loss rate T1(%) |

|---|---|---|---|---|---|

| 1 | 0 | 0 | 0 | 1.39 | 0.91 |

| 2 | -1 | -1 | 0 | 1.62 | 1.65 |

| 3 | 0 | -1 | 1 | 1.54 | 2.17 |

| 4 | 0 | 0 | 0 | 0.9 | 1.35 |

| 5 | 0 | 0 | 0 | 1.24 | 0.86 |

| 6 | 0 | 0 | 0 | 0.72 | 1.02 |

| 7 | 1 | 0 | 1 | 0.49 | 2.84 |

| 8 | 0 | 1 | 1 | 1.59 | 1.53 |

| 9 | 1 | 0 | -1 | 0.77 | 1.72 |

| 10 | 1 | 1 | 0 | 1.4 | 2.16 |

| 11 | 0 | 1 | -1 | 3.24 | 1.38 |

| 12 | 1 | -1 | 0 | 0.4 | 3.4 |

| 13 | -1 | 1 | 0 | 2.13 | 2.36 |

| 14 | -1 | 0 | 1 | 1.92 | 1.18 |

| 15 | -1 | 0 | -1 | 2.69 | 1.57 |

| 16 | 0 | -1 | -1 | 2.39 | 1.74 |

| 17 | 0 | 0 | 0 | 1.01 | 1.09 |

| 指标 Indicators | 来源 Source | 平方和 Sum of squares | Df | 均方 Mean square | F值 F value | P值 P value | 显著性 Significance |

|---|---|---|---|---|---|---|---|

| T1 | Model | 9.06 | 9 | 1.01 | 8.39 | 0.005 2 | ** |

| A | 3.51 | 1 | 3.51 | 29.30 | 0.001 0 | ** | |

| B | 0.73 | 1 | 0.73 | 6.06 | 0.043 4 | * | |

| C | 1.58 | 1 | 1.58 | 13.14 | 0.008 4 | ** | |

| AB | 0.06 | 1 | 0.06 | 0.50 | 0.502 0 | ||

| AC | 0.06 | 1 | 0.06 | 0.50 | 0.502 0 | ||

| BC | 0.16 | 1 | 0.16 | 1.33 | 0.285 8 | ||

| A2 | 0.16 | 1 | 0.16 | 1.32 | 0.289 1 | ||

| B2 | 1.18 | 1 | 1.18 | 9.83 | 0.016 5 | * | |

| C2 | 1.56 | 1 | 1.56 | 13.03 | 0.008 6 | ** | |

| 残差 | 0.84 | 7 | 0.12 | ||||

| 失拟项 | 0.55 | 3 | 0.18 | 2.60 | 0.189 6 | ||

| 误差 | 0.28 | 4 | 0.071 | ||||

| 总和 | 9.89 | 16 | |||||

| T2 | Model | 7.58 | 9 | 0.84 | 31.53 | <0.000 1 | ** |

| A | 1.41 | 1 | 1.41 | 52.83 | 0.000 2 | ** | |

| B | 0.29 | 1 | 0.29 | 10.95 | 0.012 9 | * | |

| C | 0.21 | 1 | 0.21 | 8.03 | 0.025 3 | * | |

| AB | 0.95 | 1 | 0.95 | 35.59 | 0.000 6 | ** | |

| AC | 0.57 | 1 | 0.57 | 21.34 | 0.002 4 | ** | |

| BC | 0.02 | 1 | 0.02 | 0.73 | 0.420 0 | ||

| A2 | 2.27 | 1 | 2.27 | 85.03 | <0.000 1 | ** | |

| B2 | 1.58 | 1 | 1.58 | 59.03 | 0.000 1 | ** | |

| C2 | 0.009 3 | 1 | 0.009 3 | 0.35 | 0.573 7 | ||

| 残差 | 0.19 | 7 | 0.027 | ||||

| 失拟项 | 0.039 | 3 | 0.013 | 0.35 | 0.792 6 | ||

| 误差 | 0.15 | 4 | 0.037 | ||||

| 总和 | 7.77 | 16 |

Tab.6 Variance analysis of grain impurity rate

| 指标 Indicators | 来源 Source | 平方和 Sum of squares | Df | 均方 Mean square | F值 F value | P值 P value | 显著性 Significance |

|---|---|---|---|---|---|---|---|

| T1 | Model | 9.06 | 9 | 1.01 | 8.39 | 0.005 2 | ** |

| A | 3.51 | 1 | 3.51 | 29.30 | 0.001 0 | ** | |

| B | 0.73 | 1 | 0.73 | 6.06 | 0.043 4 | * | |

| C | 1.58 | 1 | 1.58 | 13.14 | 0.008 4 | ** | |

| AB | 0.06 | 1 | 0.06 | 0.50 | 0.502 0 | ||

| AC | 0.06 | 1 | 0.06 | 0.50 | 0.502 0 | ||

| BC | 0.16 | 1 | 0.16 | 1.33 | 0.285 8 | ||

| A2 | 0.16 | 1 | 0.16 | 1.32 | 0.289 1 | ||

| B2 | 1.18 | 1 | 1.18 | 9.83 | 0.016 5 | * | |

| C2 | 1.56 | 1 | 1.56 | 13.03 | 0.008 6 | ** | |

| 残差 | 0.84 | 7 | 0.12 | ||||

| 失拟项 | 0.55 | 3 | 0.18 | 2.60 | 0.189 6 | ||

| 误差 | 0.28 | 4 | 0.071 | ||||

| 总和 | 9.89 | 16 | |||||

| T2 | Model | 7.58 | 9 | 0.84 | 31.53 | <0.000 1 | ** |

| A | 1.41 | 1 | 1.41 | 52.83 | 0.000 2 | ** | |

| B | 0.29 | 1 | 0.29 | 10.95 | 0.012 9 | * | |

| C | 0.21 | 1 | 0.21 | 8.03 | 0.025 3 | * | |

| AB | 0.95 | 1 | 0.95 | 35.59 | 0.000 6 | ** | |

| AC | 0.57 | 1 | 0.57 | 21.34 | 0.002 4 | ** | |

| BC | 0.02 | 1 | 0.02 | 0.73 | 0.420 0 | ||

| A2 | 2.27 | 1 | 2.27 | 85.03 | <0.000 1 | ** | |

| B2 | 1.58 | 1 | 1.58 | 59.03 | 0.000 1 | ** | |

| C2 | 0.009 3 | 1 | 0.009 3 | 0.35 | 0.573 7 | ||

| 残差 | 0.19 | 7 | 0.027 | ||||

| 失拟项 | 0.039 | 3 | 0.013 | 0.35 | 0.792 6 | ||

| 误差 | 0.15 | 4 | 0.037 | ||||

| 总和 | 7.77 | 16 |

| [1] | 王建廷, 李耀明, 马征, 等. 玉米收获机械关键装置结构特点及发展趋势[J]. 农机化研究, 2019, 41(9):1-8. |

| WANG Jianting, LI Yaoming, MA Zheng, et al. Structural characteristics and development trend of key devices of corn harvesting machinery[J]. Agricultural Mechanization Research, 2019, 41(9):1-8. | |

| [2] | 陈志, 郝付平, 王锋德, 等. 中国玉米收获技术与装备发展研究[J]. 农业机械学报, 2012, 43(12):44-50. |

| ChEN Zhi, HAO Fuping, WANG Fengde, et al. Research on the development of corn harvesting technology and equipment in China[J]. Journal of Agricultural Machinery, 2012, 43(12):44-50. | |

| [3] | 宗望远, 廖庆喜, 黄鹏, 等. 组合式油菜脱粒装置设计与物料运动轨迹分析[J]. 农业机械学报, 2013, 44(S2):41-46. |

| ZONG Wangyuan, LIAO Qingxi, HUANG Peng, et al. Design of combined rape threshing device and analysis of material trajectory[J]. Journal of Agricultural Machinery, 2013, 44 (S2) :41-46. | |

| [4] | 徐立章, 李耀明, 王成红, 等. 切纵流双滚筒联合收获机脱粒分离装置[J]. 农业机械学报, 2014, 45(2):105-108,135. |

| XU Lizhang, LI Yaoming, WANG Chenghong, et al. Threshing separation device of tangential and longitudinal flow double drum combine harvester[J]. Journal of Agricultural Machinery, 2014, 45 (2) :105-108,135. | |

| [5] | 李耀明, 王成红, 徐立章, 等. 切纵流联合收获机脱粒分离装置田间试验与参数优化[J]. 农业机械学报, 2014, 45(11):111-116. |

| LI Yaoming, WANG Chenghong, XU Lizhang, et al. Field experiment and parameter optimization of threshing and separating device of tangential-longitudinal flow combine harvester[J]. Journal of Agricultural Machinery, 2014, 45(11):111-116. | |

| [6] | 司增永, 李耀明, 唐忠, 等. 横置多滚筒联合收获机清选装置参数优化与试验[J]. 农机化研究, 2018, 40(7):185-189,205. |

| SI Zengyong, LI Yaoming, TANG Zhong, et al. Parameter optimization and test of cleaning device for transverse multi-roller combine harvester[J]. Agricultural Mechanization Research, 2018, 40 (07) :185-189,205. | |

| [7] | 司增永. 多滚筒联合收获机清选装置设计与试验[D]. 镇江: 江苏大学, 2017. |

| SI Zengyong. Design and test of cleaning device for multi-drum combine harvester[D]. Zhenjiang: Jiangsu University, 2017. | |

| [8] | 钟挺, 胡志超, 顾峰玮, 等. 4LZ-1.0Q型稻麦联合收获机脱粒清选部件试验与优化[J]. 农业机械学报, 2012, 43(10):76-81. |

| ZHONG Ting, HU Zhichao, GU Fengwei, et al. 4LZ-1.0Q rice-wheat combine threshing and cleaning components test and optimization[J]. Journal of Agricultural Machinery, 2012, 43 (10) :76-81. | |

| [9] | 钟挺, 胡志超, 顾峰玮, 等. 轻简型全喂入稻麦联合收获清选装置分析及设计要点探析[J]. 中国农机化, 2012,(6):67-70,77. |

| ZHONG Ting, HU Zhichao, GU Fengwei, et al. Analysis and design of light and simple full-feed rice-wheat combined harvest cleaning device[J]. China Agricultural Mechanization, 2012,(6):67-70,77. | |

| [10] | 樊晨龙, 崔涛, 张东兴. 等. 纵轴流联合收获机双层异向清选装置设计与试验[J]. 农业机械学报, 2018, 49(S1):239-248. |

| FAN Chenlong, CUI Tao, ZHANG Dongxing, et al. Design and test of two-layer opposite cleaning device for longitudinal and axial flow combine harvester[J]. Journal of Agricultural Machinery, 2018, 49 (S1) :239-248. | |

| [11] | 栗晓宇, 杜岳峰, 牛兴成, 等. 玉米清选装置结构优化设计与试验[J]. 农业机械学报, 2020, 51(S2):233-242. |

| LI Xiaoyu, DU Yuefeng, NIU Xingcheng, et al. Structural optimization design and test of corn cleaning device[J]. Journal of Agricultural Machinery, 2020, 51 (S2) :233-242. | |

| [12] | 王立军, 刘伟腾, 李懿航, 等. 大喂入量玉米籽粒收获机清选系统双层筛孔抖动板研究[J]. 农业机械学报:1-12[2022-06-27]. |

| WANG Lijun, LIU Weiteng, LI Yihang, et al. Research on double-layer sieve shaker plate for cleaning system of corn grain harvester with large feed rate[J]. Journal of Agricultural Machinery:1-12 [2022-06-27]. | |

| [13] | Ali M, Shamsollah A, Asghar M, et al. Intelligent modeling of material separation in combine harvester’s thresher by ANN[J]. International Journal of Agriculture and Crop Sciences, 2012, 4(23):1767-1777. |

| [14] |

LIANG Z W, XU L Z, Baerdemaeker J D, et al. Optimization of a multi-duct cleaning device for rice combine harvesters utilising CFD and experiments[J]. Biosystems Engineering, 2020, 190:25 -40.

DOI URL |

| [15] | 中国农业机械化科学研究院. 农业机械设计手册[M]. 北京: 中国农业科学技术出版社, 2007. |

| Chinese Academy of Agricultural Mechanization. Manual of Agricultural Machinery Design[M]. Beijing: China Agricultural Science and Technology Press, 2007. | |

| [16] | 李耀明, 王智华, 徐立章, 等. 油菜脱出物振动筛分运动分析及试验研究[J]. 农业工程学报, 2007,(9):111-114. |

| LI Yaoming, WANG Zhihua, XU Lizhang, et al. Motion analysis and experimental study on vibration screening of rapeseed extract[J]. Transactions of the Chinese Society of Agricultural Engineering, 2007,(9):111-114. | |

| [17] | 于昭洋, 胡志超, 曹明珠, 等. 切流式花生全喂入联合收获机清选机构设计[J]. 农业工程学报, 2019, 35(9):29-37. |

| YU Zhaoyang, HU Zhichao, CAO Mingzhu, et al. The cleaning mechanism design of tangential peanut full-feed combine harvester[J]. Transactions of the Chinese Society of Agricultural Engineering, 2019, 35 (9) :29-37. | |

| [18] | 贾晶霞, 张东兴. 马铃薯收获机摆动筛与块茎运动仿真分析[J]. 中国农业大学学报, 2006,(3):79-82. |

| JIA Jingxia, ZHANG Dongxing. Simulation Analysis of Potato Harvester Oscillating Screen and Tuber Movement[J]. Journal of China Agricultural University, 2006,(3):79-82. | |

| [19] | 卢琦, 徐兵, 刘芸, 等. 基于ADAMS的往复式谷物振动筛设计与试验[J]. 山西农业大学学报(自然科学版), 2019, 39(2):98-104. |

| LU Qi, XU Bing, LIU Yun. et al. Design and experiment of reciprocating grain shaker based on ADAMS[J]. Journal of Shanxi Agricultural University (Natural Science Ed.), 2019, 39(2):98- 104. | |

| [20] |

张磊, 黄康, 黄国兴, 等. 离心风机蜗壳出口结构优化研究[J]. 流体机械, 2019, 47(6):47-51.

DOI |

| ZHANG Lei, HUANG Kang, HUANG Guoxing, et al. Research on the optimization of the outlet structure of the centrifugal fan volute[J]. Fluid Machinery, 2019, 47(6):47-51. | |

| [21] | 王加浩, 刘小民, 田晨晔, 等. 多翼离心风机双圆弧叶片的参数优化设计及气动性能分析[J]. 西安交通大学学报, 2022, 56(3):94-104. |

| WANG Jiahao, LIU Xiaomin, TIAN Chenye, et al. Parameter optimization design and aerodynamic performance analysis of double-arc blades for multi-wing centrifugal fan[J]. Journal of Xi'an Jiaotong University, 2022, 56(3):94-104. |

| [1] | CAO Jian, LIU Dan. Impact of E-commerce development on the value of regional public brands of agricultural products [J]. Xinjiang Agricultural Sciences, 2024, 61(8): 2071-2080. |

| [2] | WANG Dengfeng, Gunuer Tuerxun, LI Jianjun, Hongduzi Bolati, YANG Xueyun, MENG Xiaoxiao, WU Jianyong. Pilot study on antibodies dynamics in dairy goats infected with caprine arthritis encephalitis virus [J]. Xinjiang Agricultural Sciences, 2023, 60(6): 1555-1560. |

| [3] | Maowulan , GUO Junxian, ZHU Zhaoshuai. Design and Experiment of Continuous Apricot Kernel Removal Machine [J]. Xinjiang Agricultural Sciences, 2022, 59(9): 2295-2302. |

| [4] | Maowulan , ZHU Zhaoshuai, YANG Liling, CUI Kuanbo, ZHU Zhanjiang. Optimization Research and Experimental Analysis of Apricot Fruit Cutting and De-core Mechanism [J]. Xinjiang Agricultural Sciences, 2022, 59(12): 3084-3092. |

| [5] | YANG Tingrui, ZHAO Jinghua, YANG Lei, PENG Yanping, ZHOU Heping. Study on Combination of Subsurface Irrigation Technology for Optimal Yield of Maize Based on Orthogonal Experiment [J]. Xinjiang Agricultural Sciences, 2021, 58(9): 1585-1593. |

| [6] | JI Guangpeng, ZHANG Donghai, NIU Linglei, JIANG Jiyuan, ZHAO Sifeng, WU Yurong. The Research to Function Fertilizer Effect of ‘3414’ to Confirm the Fertilization Parameter of Korla Pear in the Early Fruiting [J]. Xinjiang Agricultural Sciences, 2021, 58(4): 682-689. |

| [7] | WU Xiaomei, YUAN Yanping, WEI Xiaoru, CAO Fuxiang, CHEN Jiren, LÜ Changping, LI Yufan. Synergistic Effect of Pretreatment and Cultural Method on Lilium ×fomolongi Germination [J]. Xinjiang Agricultural Sciences, 2020, 57(7): 1276-1286. |

| [8] | YANG Wen-ting, CHEN Cheng, ZHANG Wen-ju. Optimization of the Conditions for DetoxificatioofCottonseed Meal by Gossypol Degradation Enzyme [J]. Xinjiang Agricultural Sciences, 2019, 56(6): 1122-1126. |

| [9] | YAN Cong, ZHU Rong-guang, HUANG Kun-peng, QIU Yuan-yuan, FAN Zhong-jian, MENG Ling-feng. Experiment and Analysis of Influencing Factors on Near-Infrared Spectral Quality of Mutton [J]. Xinjiang Agricultural Sciences, 2018, 55(5): 974-980. |

| [10] | XU Qiang, WANG Wei-chao, XU Yong-mei, SHAO Hua-wei, YANG Jin-yu, QIAO Xiao-yan, Lü Cai-xia. Chemical Fertilizer Reduction and Organic Fertilizer Supplement to Improve the Yield and Sugar Content of Muskmelon in Xinjiang [J]. Xinjiang Agricultural Sciences, 2017, 54(8): 1450-1459. |

| [11] | ZHANG Jie;LI Hao;KONG Li-zhuo;Paherding;SU Jian;MA Juan;FENG Bin. Experimental Study on Processing Parameters of Granulation of Stalk Combined Pellet Feed [J]. , 2017, 54(7): 1313-1322. |

| [12] | LI Na;CHEN Chao;MA Cai-wen;ZHOU Ping;LING Hao-shu;ZHANG Ming-xing. Simulation Calculation on Solar Greenhouse Optimum Orientation Based on the Principle of Building Thermal [J]. , 2016, 53(11): 2112-2118. |

| [13] | XU Ye-ting;YANG Lei;YANG Bo;DAI Pei-hong;XIE Hui;GONG Peng;LU Chun-sheng. Study on the Effects of Nitrogen, Phosphorus and Potassium on Almond Based on 3414 Field Experiments in Xinjiang Shache County [J]. , 2015, 52(12): 2215-2221. |

| [14] | YIN Dan-dan;CHAO Qun-fang;WANG Li-xin;WEI Chao-ying;YANG Bin-yin;CHEN Zhi-dan;YAO Xiao-yun. Selective Activation Condition of Stratal Microflora in Karamay Oil Field [J]. , 2015, 52(1): 102-108. |

| [15] | QI Hong-liang;CUI Wei-dong;BAO Hui-fang;ZHAN Fa-qiang;WANG Ning;HOU Min;WANG Wei. Optimization of Liquid Fermentation Medium for the Culture of Candida utilis [J]. , 2014, 51(11): 2046-2052. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||