Xinjiang Agricultural Sciences ›› 2022, Vol. 59 ›› Issue (12): 3084-3092.DOI: 10.6048/j.issn.1001-4330.2022.12.024

• Crop Genetics and Breeding · Cultivation Physiology · Germplasm Resources • Previous Articles Next Articles

Maowulan ( ), ZHU Zhaoshuai(

), ZHU Zhaoshuai( ), YANG Liling, CUI Kuanbo, ZHU Zhanjiang

), YANG Liling, CUI Kuanbo, ZHU Zhanjiang

Received:2022-02-10

Online:2022-12-20

Published:2023-01-30

Correspondence author:

ZHU Zhaoshuai

Supported by:通讯作者:

祝兆帅

作者简介:毛吾兰(1988-),男,新疆人,助理研究员,研究方向为农业机械化与装备工程,(E-mail)611253450@qq.com

基金资助:CLC Number:

Maowulan , ZHU Zhaoshuai, YANG Liling, CUI Kuanbo, ZHU Zhanjiang. Optimization Research and Experimental Analysis of Apricot Fruit Cutting and De-core Mechanism[J]. Xinjiang Agricultural Sciences, 2022, 59(12): 3084-3092.

毛吾兰, 祝兆帅, 杨莉玲, 崔宽波, 朱占江. 杏果切分去核机构优化及作业参数分析[J]. 新疆农业科学, 2022, 59(12): 3084-3092.

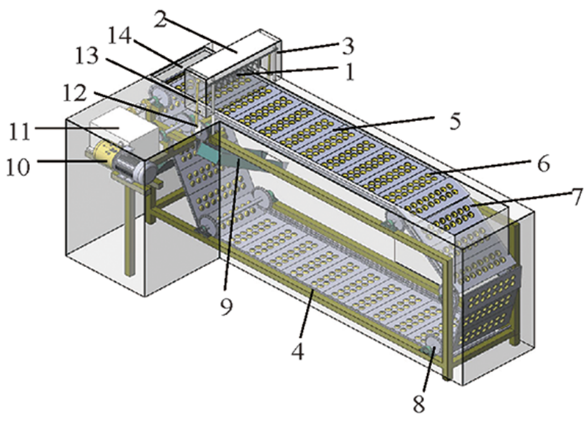

Fig.3 Structure of continuous apricot kernel remover Note: 1. Cutter; 2. Core removal mechanism; 3. Guide rail; 4. Frame; 5. Conveyor chain; 6. Limiting brush; 7. Discharge port; 8. Apricot kernel discharge; 9. Divider port; 10. Crankshaft connecting rod; 11. Apricot flesh discharge port; 12. Linear bearing

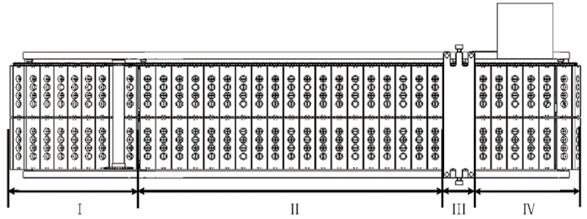

Fig.4 Internal structure of the denuclearization mechanism Note: Ⅰfeeding and conveying area;Ⅱ manual assisted positio-ning area;Ⅲ cutting and nucleating area;Ⅳ collection area

| 参数 Parameter | 指标 Index |

|---|---|

| 整机尺寸(长×宽×高) Machine size (length×width×height) (mm) | 4 200×1 260 ×1 500 |

| 整机功率Whole machine power (KW) | 1.5 |

| 输入电压Input voltage (V) | 380 |

| 输出电流频率Output current frequency (Hz) | 15-50 |

| 排序输送倾角Sorting conveyor inclination (°) | 30 |

| 入料口高度Inlet height (mm) | 900-1 250 |

| 出料口高度Height of discharge port (mm) | 600-830 |

| 加工效率Processing efficiency (kg/h) | 500 |

Table 1 Technical parameters of fresh apricot cutting and nucleating machine

| 参数 Parameter | 指标 Index |

|---|---|

| 整机尺寸(长×宽×高) Machine size (length×width×height) (mm) | 4 200×1 260 ×1 500 |

| 整机功率Whole machine power (KW) | 1.5 |

| 输入电压Input voltage (V) | 380 |

| 输出电流频率Output current frequency (Hz) | 15-50 |

| 排序输送倾角Sorting conveyor inclination (°) | 30 |

| 入料口高度Inlet height (mm) | 900-1 250 |

| 出料口高度Height of discharge port (mm) | 600-830 |

| 加工效率Processing efficiency (kg/h) | 500 |

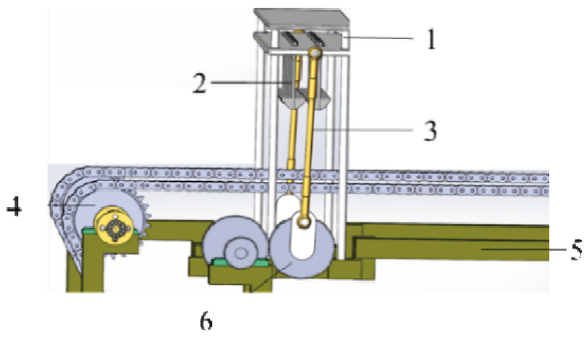

Fig.5 Schematic diagram of the structure of non-nuclear institutions Note: 1. Knife holder; 2. Core removal tool; 3. Crankshaft connecting rod; 4. Drive sprocket; 5. Frame; 6. Drive sprocket

| 水平 Levels | 刀具类型 Tool type A | 曲柄转速 Crank speed B (r/min) | 刀头与 刀片距离 Distance between cutter head and blade C(mm) | 离核性 Nucleus D |

|---|---|---|---|---|

| 1 | 刀具A1 | 36 | 20 | 离核型 |

| 2 | 刀具A2 | 41 | 0 | 粘核型 |

| 3 | 刀具A3 | 46 | -20 | 离核型 |

Table 2 Test factors and levels

| 水平 Levels | 刀具类型 Tool type A | 曲柄转速 Crank speed B (r/min) | 刀头与 刀片距离 Distance between cutter head and blade C(mm) | 离核性 Nucleus D |

|---|---|---|---|---|

| 1 | 刀具A1 | 36 | 20 | 离核型 |

| 2 | 刀具A2 | 41 | 0 | 粘核型 |

| 3 | 刀具A3 | 46 | -20 | 离核型 |

| 试验号 Test number | A | B | C | D | 试验指标 test index yg | y2g | |

|---|---|---|---|---|---|---|---|

| 1 | 1 | 1 | 1 | 1 | 1 | 2.53 | 6.40 |

| 2 | 1 | 2 | 2 | 2 | 2 | 8.83 | 77.97 |

| 3 | 1 | 3 | 3 | 3 | 2 | 10.81 | 116.86 |

| 4 | 2 | 1 | 3 | 2 | 2 | 9.26 | 85.75 |

| 5 | 2 | 2 | 1 | 3 | 2 | 9.34 | 87.24 |

| 6 | 2 | 3 | 2 | 1 | 1 | 5.32 | 28.30 |

| 7 | 3 | 1 | 2 | 3 | 2 | 9.46 | 89.49 |

| 8 | 3 | 2 | 3 | 1 | 1 | 3.08 | 9.49 |

| 9 | 3 | 3 | 1 | 2 | 2 | 10.12 | 102.41 |

| K1j | 22.17 | 21.25 | 21.99 | 10.93 | R= W= P= ST=W-P=78.74 | ||

| K2j | 23.92 | 21.25 | 23.61 | 57.82 | |||

| K3j | 22.66 | 26.25 | 23.15 | — | |||

| 491.51 | 451.56 | 483.56 | 119.46 | ||||

| 572.17 | 451.56 | 557.43 | 3343.15 | ||||

| 513.48 | 689.06 | 535.92 | — | ||||

| Qj= | 525.72 | 530.73 | 525.64 | 597.01 | |||

| Sj=Qi-P | 0.55 | 5.56 | 0.47 | 71.84 | |||

Table 3 Experiment design and results

| 试验号 Test number | A | B | C | D | 试验指标 test index yg | y2g | |

|---|---|---|---|---|---|---|---|

| 1 | 1 | 1 | 1 | 1 | 1 | 2.53 | 6.40 |

| 2 | 1 | 2 | 2 | 2 | 2 | 8.83 | 77.97 |

| 3 | 1 | 3 | 3 | 3 | 2 | 10.81 | 116.86 |

| 4 | 2 | 1 | 3 | 2 | 2 | 9.26 | 85.75 |

| 5 | 2 | 2 | 1 | 3 | 2 | 9.34 | 87.24 |

| 6 | 2 | 3 | 2 | 1 | 1 | 5.32 | 28.30 |

| 7 | 3 | 1 | 2 | 3 | 2 | 9.46 | 89.49 |

| 8 | 3 | 2 | 3 | 1 | 1 | 3.08 | 9.49 |

| 9 | 3 | 3 | 1 | 2 | 2 | 10.12 | 102.41 |

| K1j | 22.17 | 21.25 | 21.99 | 10.93 | R= W= P= ST=W-P=78.74 | ||

| K2j | 23.92 | 21.25 | 23.61 | 57.82 | |||

| K3j | 22.66 | 26.25 | 23.15 | — | |||

| 491.51 | 451.56 | 483.56 | 119.46 | ||||

| 572.17 | 451.56 | 557.43 | 3343.15 | ||||

| 513.48 | 689.06 | 535.92 | — | ||||

| Qj= | 525.72 | 530.73 | 525.64 | 597.01 | |||

| Sj=Qi-P | 0.55 | 5.56 | 0.47 | 71.84 | |||

| 方差来源 Soruce of variation | 平方和 sum of squares | 自由度 Degree of freedom | 均方差 mean square error | F比及 显著性 F ratio and significance |

|---|---|---|---|---|

| A | 0.55 | 2 | 0.28 | 1.83 |

| B | 5.56 | 2 | 2.78 | 18.53※ |

| C | 0.47 | 2 | 0.24 | 1.57 |

| D | 71.84 | 1 | 71.84 | 239.47※ |

| 误差error E | 0.3 | 1 | 0.3 | — |

| 总和total | 78.74 | 8 | — | — |

Table 4 Variance analysis

| 方差来源 Soruce of variation | 平方和 sum of squares | 自由度 Degree of freedom | 均方差 mean square error | F比及 显著性 F ratio and significance |

|---|---|---|---|---|

| A | 0.55 | 2 | 0.28 | 1.83 |

| B | 5.56 | 2 | 2.78 | 18.53※ |

| C | 0.47 | 2 | 0.24 | 1.57 |

| D | 71.84 | 1 | 71.84 | 239.47※ |

| 误差error E | 0.3 | 1 | 0.3 | — |

| 总和total | 78.74 | 8 | — | — |

| 品种 Varieties | 样本质量 sample quality (kg) | 生产率 productivity (kg/h) | 杏肉损失率 Loss rate of apricot flesh (%) |

|---|---|---|---|

| 赛买提杏Saimaiti apricot | 80 | 640 | 2.8 |

| 乔勒潘杏Qiaolepan apricot | 80 | 639 | 2.7 |

| 胡安娜杏Huanna apricot | 80 | 643 | 3.0 |

| 克孜郎杏Keailang apricot | 80 | 641 | 3.4 |

| 黑叶杏Heiye apricot | 80 | 633 | 9.6 |

| 对照组Control group | 80 | 554 | 3.5 |

Table 5 Verification test results

| 品种 Varieties | 样本质量 sample quality (kg) | 生产率 productivity (kg/h) | 杏肉损失率 Loss rate of apricot flesh (%) |

|---|---|---|---|

| 赛买提杏Saimaiti apricot | 80 | 640 | 2.8 |

| 乔勒潘杏Qiaolepan apricot | 80 | 639 | 2.7 |

| 胡安娜杏Huanna apricot | 80 | 643 | 3.0 |

| 克孜郎杏Keailang apricot | 80 | 641 | 3.4 |

| 黑叶杏Heiye apricot | 80 | 633 | 9.6 |

| 对照组Control group | 80 | 554 | 3.5 |

| [1] | 于希志. 试谈我国杏生产现状与对策[J]. 北方果树, 2003,(5):24-26. |

| YU Xizhi. Try to talk about the current situation and countermeasures of apricot production in my country[J]. Northern Fruits, 2003,(5):24-26. | |

| [2] | 肖朝霞, 蒋萌蒙, 王向军. 杏仁的功能性及其药理研究进展[J]. 农产品加工, 2011,(11):71-73. |

| XIAO Zhaoxia, JIANG Mengmeng, WANG Xiangjun. Research progress of almond's function and its pharmacology[J]. Farm Products Processing, 2011,(11):71-73. | |

| [3] | 谢辉, 艾尼瓦尔·肉孜, 王乔, 等. 新疆杏产业发展现状分析及前景展望[J]. 中国果树, 2019,(2):108-112. |

| XIE Hui, Ainiwaer Rouzi, WANG Qiao, et al. Analysis and prospect of apricot industry development in Xinjiang[J]. China Fruits, 2019,(2):108-112. | |

| [4] | 赵晓梅, 张谦, 过利敏, 等. 新疆主栽杏品种经济性状主成分分析及优良品种的选择[J]. 新疆农业科学, 2010, 47(12):2426-2430. |

| ZHAO Xiaomei, ZHANG Qian, GUO Limin, et al. Analysis on Principal Component of the Main Economic Characters and Selection of Superior Variety of Apricot in Xinjiang[J]. Xinjiang Agricultural Sciences, 2010, 47(12):2426-2430. | |

| [5] | 刘奎, 杨莉玲, 朱占江, 等. 连续式杏果去核机设计[J]. 食品与机械, 2019, 35(2):113-116, 122. |

| LIU Kui, YANG Liling, ZHU Zhanjiang, et al. Design of continuous apricot kernel removing machine[J]. Food and Machinery, 2019, 35(2): 113-116, 122. | |

| [6] | 邓干然, 李明, 连文伟. 我国核果类水果去核机具的现状及亟待研究的技术问题探讨[J]. 粮油加工与食品机械, 1999,(3):2-3. |

| DENG Ganran, LI Ming, LIAN Wenwei. The present situation of stone fruit dehulling machines in China and the discussion on the urgent technical problems[J]. Grain and Oil Processing and Food Machinery, 1999,(3): 2-3. | |

| [7] | 张秀军, 金莹, 何蔚娟. 核果类水果去核机现状的分析[J]. 中国农村小康科技, 2005,(3):33-34. |

| ZHANG Xiujun, JIN Ying, HE Weijuan. Analysis on the current situation of stone fruit dehuller[J]. China Rural Well-off Science and Technology, 2005,(3): 33-34. | |

| [8] | 康宁波, 尚梦玉, 何建国, 等. 链式气动冲切自动化干红枣去核机设计[J]. 农业工程学报, 2018, 34(22):19-26. |

| KANG Ningbo, SHANG Mengyu, HE Jianguo, et al. Design of chained pneumatic punching automatic dried jujube pit removing machine[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(22):19-26. | |

| [9] | 陶学恒, 李宝玉, 王慧慧. 新型桃子切瓣挖核机控制系统设计[J]. 农机化研究, 2015,(10):232-2234 |

| TAO Xueheng, LI Baoyu, WANG Huihui. The Control System Design of New Peach Cutting and Enucleating Machine[J]. Journal of Agricultural Mechanization Research, 2015,(10):232-2234. | |

| [10] | 黄亮. 全自动山楂去核机的研制与试验研究[D]. 福州: 福建农林大学, 2014. |

| HUANG Liang. Development and Experimental Study of Automatic Hawthorn Nuclear Machine[D]. Fuzhou: Fujian Agriculture and Forestry University, 2014. | |

| [11] | 王永芳, 胡建胜, 刘奎. 小白杏去核机构的设计及试验分析[J]. 新疆农机化, 2017,(6):32-33, 37. |

| WANG Yongfang, HU Jiansheng, LIU Kui. Test and Analysis of Small White Apricot Kermel Removal Mechanism[J]. Xinjiang Agricultural Mechanization, 2017,(6):32-33, 37. | |

| [12] | 王永芳, 胡建胜, 刘奎. 气动式杏子去核机的研究[J]. 轻工科技, 2018, 34(3):39-40, 66. |

| WANG Yongfang, HU Jiansheng, LIU Kui. Research on pneumatic apricot kernel remover[J]. Light Industry Science and Technology, 2018, 34(3): 39-40, 66. | |

| [13] | 刘向东. 鲜杏定向切分去核机理及装置试验研究[D]. 沈阳: 沈阳农业大学, 2016. |

| LIU Xiangdong. Experimental study on the mechanism and device of directional cutting and enucleation of fresh apricot[D]. Shenyang: Shenyang Agricultural University, 2016. | |

| [14] | 刘向东, 梁勤安, 李胜, 等. 6QHX-1型杏切分去核机的研制[J]. 新疆农机化, 2012,(5):5-6. |

| LIU Xiangdong, LIANG Qin'an, LI Sheng, et al. Development of 6qhx-1 apricot cutting and kernel removing machine[J]. Xinjiang Agricultural Mechanization, 2012, (5): 5-6. | |

| [15] | 张杰, 刘向东, 梁勤安, 等. 杏切分去核对杏果实物斜特性的基本要求[J]. 农产品加工, 2009,(2):75-76. |

| ZHANG Jie, LIU Xiangdong, LIANG Qin'an, et al. Basic requirements of apricot segmentation to check the skew characteristics of apricot fruit[J]. Agricultural Products Processing, 2009, (2): 75-76. | |

| [16] | 罗建清. 杏果切分机圆盘刀具优化研究[J]. 机械设计与制造, 2015,(12):1-3. |

| LUO Jianqing. Study on Optimization Disk Cutter of Apricot Fruit Cut Extension[J]. Machinery Design & Manufacture, 2015,(12): 1-3. |

| [1] | CAO Jian, LIU Dan. Impact of E-commerce development on the value of regional public brands of agricultural products [J]. Xinjiang Agricultural Sciences, 2024, 61(8): 2071-2080. |

| [2] | WANG Dengfeng, Gunuer Tuerxun, LI Jianjun, Hongduzi Bolati, YANG Xueyun, MENG Xiaoxiao, WU Jianyong. Pilot study on antibodies dynamics in dairy goats infected with caprine arthritis encephalitis virus [J]. Xinjiang Agricultural Sciences, 2023, 60(6): 1555-1560. |

| [3] | ZHANG Wei, JIN Fan, LI Qianxu, ZHANG Junsan, ZHAI Xiuping, WANG Shanbo. Design and experiment of cleaning device for corn grain combine harvester [J]. Xinjiang Agricultural Sciences, 2023, 60(12): 3102-3112. |

| [4] | Maowulan , GUO Junxian, ZHU Zhaoshuai. Design and Experiment of Continuous Apricot Kernel Removal Machine [J]. Xinjiang Agricultural Sciences, 2022, 59(9): 2295-2302. |

| [5] | YANG Tingrui, ZHAO Jinghua, YANG Lei, PENG Yanping, ZHOU Heping. Study on Combination of Subsurface Irrigation Technology for Optimal Yield of Maize Based on Orthogonal Experiment [J]. Xinjiang Agricultural Sciences, 2021, 58(9): 1585-1593. |

| [6] | JI Guangpeng, ZHANG Donghai, NIU Linglei, JIANG Jiyuan, ZHAO Sifeng, WU Yurong. The Research to Function Fertilizer Effect of ‘3414’ to Confirm the Fertilization Parameter of Korla Pear in the Early Fruiting [J]. Xinjiang Agricultural Sciences, 2021, 58(4): 682-689. |

| [7] | WU Xiaomei, YUAN Yanping, WEI Xiaoru, CAO Fuxiang, CHEN Jiren, LÜ Changping, LI Yufan. Synergistic Effect of Pretreatment and Cultural Method on Lilium ×fomolongi Germination [J]. Xinjiang Agricultural Sciences, 2020, 57(7): 1276-1286. |

| [8] | YANG Wen-ting, CHEN Cheng, ZHANG Wen-ju. Optimization of the Conditions for DetoxificatioofCottonseed Meal by Gossypol Degradation Enzyme [J]. Xinjiang Agricultural Sciences, 2019, 56(6): 1122-1126. |

| [9] | YAN Cong, ZHU Rong-guang, HUANG Kun-peng, QIU Yuan-yuan, FAN Zhong-jian, MENG Ling-feng. Experiment and Analysis of Influencing Factors on Near-Infrared Spectral Quality of Mutton [J]. Xinjiang Agricultural Sciences, 2018, 55(5): 974-980. |

| [10] | XU Qiang, WANG Wei-chao, XU Yong-mei, SHAO Hua-wei, YANG Jin-yu, QIAO Xiao-yan, Lü Cai-xia. Chemical Fertilizer Reduction and Organic Fertilizer Supplement to Improve the Yield and Sugar Content of Muskmelon in Xinjiang [J]. Xinjiang Agricultural Sciences, 2017, 54(8): 1450-1459. |

| [11] | ZHANG Jie;LI Hao;KONG Li-zhuo;Paherding;SU Jian;MA Juan;FENG Bin. Experimental Study on Processing Parameters of Granulation of Stalk Combined Pellet Feed [J]. , 2017, 54(7): 1313-1322. |

| [12] | LI Na;CHEN Chao;MA Cai-wen;ZHOU Ping;LING Hao-shu;ZHANG Ming-xing. Simulation Calculation on Solar Greenhouse Optimum Orientation Based on the Principle of Building Thermal [J]. , 2016, 53(11): 2112-2118. |

| [13] | XU Ye-ting;YANG Lei;YANG Bo;DAI Pei-hong;XIE Hui;GONG Peng;LU Chun-sheng. Study on the Effects of Nitrogen, Phosphorus and Potassium on Almond Based on 3414 Field Experiments in Xinjiang Shache County [J]. , 2015, 52(12): 2215-2221. |

| [14] | YIN Dan-dan;CHAO Qun-fang;WANG Li-xin;WEI Chao-ying;YANG Bin-yin;CHEN Zhi-dan;YAO Xiao-yun. Selective Activation Condition of Stratal Microflora in Karamay Oil Field [J]. , 2015, 52(1): 102-108. |

| [15] | QI Hong-liang;CUI Wei-dong;BAO Hui-fang;ZHAN Fa-qiang;WANG Ning;HOU Min;WANG Wei. Optimization of Liquid Fermentation Medium for the Culture of Candida utilis [J]. , 2014, 51(11): 2046-2052. |

| Viewed | ||||||||||||||||||||||||||||||||||||||||||||||||||

|

Full text 69

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Abstract 204

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||