Xinjiang Agricultural Sciences ›› 2024, Vol. 61 ›› Issue (2): 345-354.DOI: 10.6048/j.issn.1001-4330.2024.02.010

• Horticultural Special Local Products· Soil Fertilizer·Plant Protection • Previous Articles Next Articles

MA Yunlong1,2( ), XIE Hui2, ZHANG Wen2, ZHU Xuehui2,3, WANG Yanmeng2,3, MAI Sile2,3, ZHANG Jiaxi1(

), XIE Hui2, ZHANG Wen2, ZHU Xuehui2,3, WANG Yanmeng2,3, MAI Sile2,3, ZHANG Jiaxi1( )

)

Received:2023-06-18

Online:2024-02-20

Published:2024-03-19

Correspondence author:

ZHANG Jiaxi(1973-), male, associate professor, research field:design and experimental study of agricultural and animal husbandry machinery, (E-mail)Supported by:

马云龙1,2( ), 谢辉2, 张雯2, 朱学慧2,3, 王艳蒙2,3, 麦斯乐2,3, 张佳喜1(

), 谢辉2, 张雯2, 朱学慧2,3, 王艳蒙2,3, 麦斯乐2,3, 张佳喜1( )

)

通讯作者:

张佳喜(1973-),男,研究员,研究方向为农牧业机械,(E-mail)作者简介:马云龙(1996-),男,硕士研究生,研究方向为果蔬干燥,(E-mail)1286001135@qq.com

基金资助:CLC Number:

MA Yunlong, XIE Hui, ZHANG Wen, ZHU Xuehui, WANG Yanmeng, MAI Sile, ZHANG Jiaxi. Effects of temperature on color and drying characteristics of green raisins[J]. Xinjiang Agricultural Sciences, 2024, 61(2): 345-354.

马云龙, 谢辉, 张雯, 朱学慧, 王艳蒙, 麦斯乐, 张佳喜. 温度对绿色葡萄干色泽及干燥特性的影响[J]. 新疆农业科学, 2024, 61(2): 345-354.

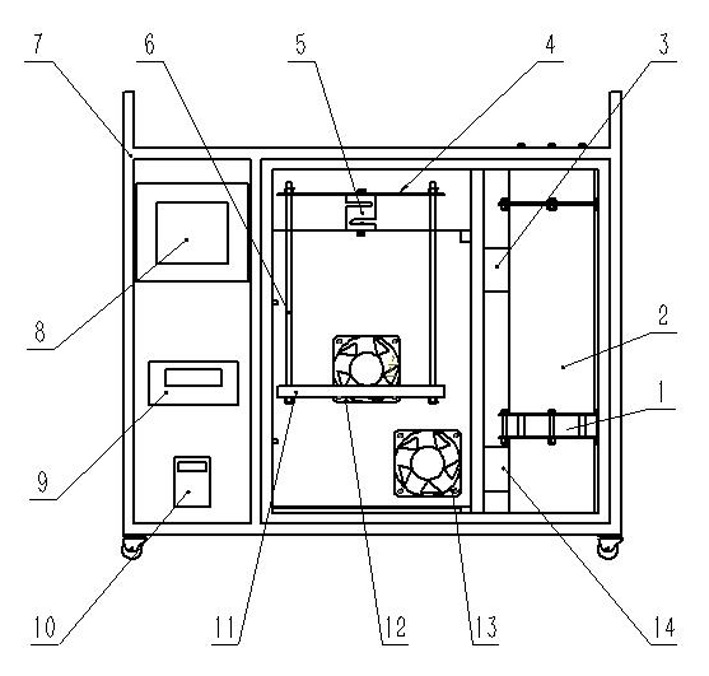

Fig.1 Structure diagram of drying device Note:1.Fan;2.Heating device;3.Air Intake;4.Balance board;5.Weighing sensor;6.Screw rod;7.Rack;8.Touch screen;9.Weight digital display;10.Frequency converter;11.Tray;12.Fan;13.Fan;14.ari outlet

| 序号No. | 模型名称Model name | 模型公式Model equation |

|---|---|---|

| 1 | Weibull | MR=exp(-(t/b)a) |

| 2 | Henderson and pabis | MR=aexp(-kt) |

| 3 | Logarithmic model | MR=aexp(-kt)+c |

| 4 | Midilli et al. | MR=aexp(-ktn)+bt |

| 5 | Modified enderson and pabis | MR=aexp(-kt)+bexp(-gt)+cexp(+ht) |

| 6 | Newton(single-term exponential) | MR=exp(-kt) |

| 7 | Page | MR=exp(-ktn) |

| 8 | Two-term Logarithmic model | MR=aexp(-k0t)+bexp(-k1t) |

| 9 | Verma et al. | MR=aexp(-kt)+(1-a)exp(-gt) |

| 10 | Wang and singh | MR=1+at+bt2 |

Tab.1 Common 10 drying models

| 序号No. | 模型名称Model name | 模型公式Model equation |

|---|---|---|

| 1 | Weibull | MR=exp(-(t/b)a) |

| 2 | Henderson and pabis | MR=aexp(-kt) |

| 3 | Logarithmic model | MR=aexp(-kt)+c |

| 4 | Midilli et al. | MR=aexp(-ktn)+bt |

| 5 | Modified enderson and pabis | MR=aexp(-kt)+bexp(-gt)+cexp(+ht) |

| 6 | Newton(single-term exponential) | MR=exp(-kt) |

| 7 | Page | MR=exp(-ktn) |

| 8 | Two-term Logarithmic model | MR=aexp(-k0t)+bexp(-k1t) |

| 9 | Verma et al. | MR=aexp(-kt)+(1-a)exp(-gt) |

| 10 | Wang and singh | MR=1+at+bt2 |

| 温度 Temperature (℃) | L | a | b | ΔE | C | h0 | 绿品率 Green rate (%) |

|---|---|---|---|---|---|---|---|

| 30 | 5.77±4.81c | 5.82±1.13a | 10.47±4.73c | 16.80±5.11a | 12.15±4.39c | 1.01±0.17b | 0.41±0.03c |

| 32.5 | 9.38±4.27b | 3.15±4.38a | 16.50±2.52b | 11.92±3.92b | 17.26±3.16b | 0.99±0.64b | 0.43±0.04c |

| 35 | 14.56±3.25a | 2.98±1.06a | 17.94±2.37b | 6.99±2.72c | 18.23±2.31b | 1.40±0.07a | 0.64±0.02a |

| 37.5 | 11.41±2.8b | 3.96±1.76a | 20.56±3.07a | 11.05±1.53b | 21.04±2.82a | 1.37±0.10a | 0.54±0.03b |

| 40 | 10.68±4.64b | 5.00±6.45a | 16.04±4.43b | 13.22±3.5b | 17.69±5.42b | 0.87±0.58b | 0.46±0.01c |

Tab.2 Color index at different temperature

| 温度 Temperature (℃) | L | a | b | ΔE | C | h0 | 绿品率 Green rate (%) |

|---|---|---|---|---|---|---|---|

| 30 | 5.77±4.81c | 5.82±1.13a | 10.47±4.73c | 16.80±5.11a | 12.15±4.39c | 1.01±0.17b | 0.41±0.03c |

| 32.5 | 9.38±4.27b | 3.15±4.38a | 16.50±2.52b | 11.92±3.92b | 17.26±3.16b | 0.99±0.64b | 0.43±0.04c |

| 35 | 14.56±3.25a | 2.98±1.06a | 17.94±2.37b | 6.99±2.72c | 18.23±2.31b | 1.40±0.07a | 0.64±0.02a |

| 37.5 | 11.41±2.8b | 3.96±1.76a | 20.56±3.07a | 11.05±1.53b | 21.04±2.82a | 1.37±0.10a | 0.54±0.03b |

| 40 | 10.68±4.64b | 5.00±6.45a | 16.04±4.43b | 13.22±3.5b | 17.69±5.42b | 0.87±0.58b | 0.46±0.01c |

| 温度 Temperature (℃) | 叶绿素 Chlorophyll | 叶绿素a Chlorophyll a | 叶绿素b Chlorophyll b | 类胡萝卜素 Carotenoid | 总酚 Total phenols |

|---|---|---|---|---|---|

| 30 | 0.37±0.01d | 0.13±0.01d | 0.23±0.01d | 0.70±0.04c | 0.30±0.07a |

| 32.5 | 0.42±0.01c | 0.15±0.01c | 0.27±0.01c | 0.81±0.03b | 0.25±0.13b |

| 35 | 0.55±0.03a | 0.19±0.01a | 0.36±0.02a | 0.94±0.02a | 0.15±0.12d |

| 37.5 | 0.47±0.01b | 0.17±0.01b | 0.30±0.01b | 0.72±0.01c | 0.19±0.07c |

| 40 | 0.39±0.01d | 0.14±0.01d | 0.25±0.01d | 0.64±0.01d | 0.20±0.03c |

Tab.3 Chlorophyll and total phenol of raisins at different temperatures

| 温度 Temperature (℃) | 叶绿素 Chlorophyll | 叶绿素a Chlorophyll a | 叶绿素b Chlorophyll b | 类胡萝卜素 Carotenoid | 总酚 Total phenols |

|---|---|---|---|---|---|

| 30 | 0.37±0.01d | 0.13±0.01d | 0.23±0.01d | 0.70±0.04c | 0.30±0.07a |

| 32.5 | 0.42±0.01c | 0.15±0.01c | 0.27±0.01c | 0.81±0.03b | 0.25±0.13b |

| 35 | 0.55±0.03a | 0.19±0.01a | 0.36±0.02a | 0.94±0.02a | 0.15±0.12d |

| 37.5 | 0.47±0.01b | 0.17±0.01b | 0.30±0.01b | 0.72±0.01c | 0.19±0.07c |

| 40 | 0.39±0.01d | 0.14±0.01d | 0.25±0.01d | 0.64±0.01d | 0.20±0.03c |

| 编号 No. | 模型名称 Name of model | 常数 Constant | 干燥温度 Drying conditions(℃) | ||||

|---|---|---|---|---|---|---|---|

| 30 | 32.5 | 35 | 37.5 | 40 | |||

| 1 | Weibull | a | 0.022 57 | 0.024 74 | 0.024 57 | 0.046 95 | 0.039 18 |

| b | 2.009 3 | 2.075 15 | 1.901 73 | 2.974 5 | 1.827 79 | ||

| 2 | Henderson and pabis | a | 1.097 12 | 1.095 35 | 1.109 92 | 1.078 42 | 1.039 05 |

| k | 0.012 33 | 0.013 07 | 0.014 34 | 0.017 03 | 0.022 25 | ||

| 3 | Logarithmic model | a | 1.357 4 | 1.334 | 1.362 69 | 1.198 53 | 1.089 04 |

| k | 0.006 93 | 0.007 6 | 0.008 2 | 0.012 09 | 0.017 99 | ||

| c | -0.330 68 | -0.305 37 | -0.321 54 | -0.166 53 | -0.083 12 | ||

| 4 | Midilli et al. | a | 1.026 72 | 1.449 3 | 1.041 14 | 1.433 48 | 1.009 93 |

| k | 2.722 0 | 0.032 05 | -0.504 1 | 0.507 8 | 0.003 2 | ||

| n | -5.738 15 | -5.716 08 | -5.721 61 | -5.592 83 | 0.032 05 | ||

| b | 0.001 71 | 0.001 54 | 0.001 97 | 0.001 83 | -4.570 2E-4 | ||

| 5 | Modified enderson and pabis | a | 0.365 72 | 0.365 12 | 0.369 98 | 0.359 47 | 0.595 32 |

| k | 0.012 33 | 0.013 07 | 0.014 34 | 0.017 03 | 0.087 43 | ||

| b | 0.365 72 | 0.365 12 | 0.369 98 | 0.359 47 | 22.164 49 | ||

| g | 0.012 33 | 0.013 07 | 0.014 34 | 0.017 03 | 0.039 35 | ||

| c | 0.365 72 | 0.365 12 | 0.369 98 | 0.359 47 | -21.762 84 | ||

| h | 0.012 33 | 0.013 07 | 0.014 34 | 0.017 03 | 0.041 42 | ||

| 6 | Newton | k | 0.011 23 | 0.011 92 | 0.012 92 | 0.015 78 | 0.021 44 |

| 7 | Page | k | -0.105 99 | -0.109 21 | -0.113 68 | -0.125 64 | 0.0188 5 |

| n | -0.105 99 | -0.109 21 | -0.113 68 | -0.125 64 | 1.137 07 | ||

| 8 | Two-term Logarithmic model | a | 0.548 56 | 0.547 69 | 0.554 95 | 0.539 2 | -18.800 28 |

| K0 | 0.012 33 | 0.013 07 | 0.014 34 | 0.017 03 | 0.035 68 | ||

| b | 0.548 56 | 0.547 69 | 0.554 95 | 0.539 2 | 19.773 3 | ||

| K1 | 0.012 33 | 0.013 07 | 0.014 34 | 1.017 03 | 0.034 56 | ||

| 9 | Verma et al. | a | 1.118 35 | 1.117 63 | 1.138 21 | 1.103 26 | 55.232 05 |

| k | 0.012 57 | 0.013 34 | 0.014 7 | 0.017 43 | 0.033 94 | ||

| g | 15.304 4 | 15.714 88 | 15.856 79 | 16.038 18 | 0.034 28 | ||

| 10 | Wang and singh | a | -0.008 1 | -0.008 67 | -0.009 32 | -0.011 82 | -0.015 47 |

| b | 1.58878E-5 | 1.84101E-5 | 2.09099E-5 | 3.61915E-5 | 6.1261E-5 | ||

Tab.4 The fitting constants of 10 models at different temperatures

| 编号 No. | 模型名称 Name of model | 常数 Constant | 干燥温度 Drying conditions(℃) | ||||

|---|---|---|---|---|---|---|---|

| 30 | 32.5 | 35 | 37.5 | 40 | |||

| 1 | Weibull | a | 0.022 57 | 0.024 74 | 0.024 57 | 0.046 95 | 0.039 18 |

| b | 2.009 3 | 2.075 15 | 1.901 73 | 2.974 5 | 1.827 79 | ||

| 2 | Henderson and pabis | a | 1.097 12 | 1.095 35 | 1.109 92 | 1.078 42 | 1.039 05 |

| k | 0.012 33 | 0.013 07 | 0.014 34 | 0.017 03 | 0.022 25 | ||

| 3 | Logarithmic model | a | 1.357 4 | 1.334 | 1.362 69 | 1.198 53 | 1.089 04 |

| k | 0.006 93 | 0.007 6 | 0.008 2 | 0.012 09 | 0.017 99 | ||

| c | -0.330 68 | -0.305 37 | -0.321 54 | -0.166 53 | -0.083 12 | ||

| 4 | Midilli et al. | a | 1.026 72 | 1.449 3 | 1.041 14 | 1.433 48 | 1.009 93 |

| k | 2.722 0 | 0.032 05 | -0.504 1 | 0.507 8 | 0.003 2 | ||

| n | -5.738 15 | -5.716 08 | -5.721 61 | -5.592 83 | 0.032 05 | ||

| b | 0.001 71 | 0.001 54 | 0.001 97 | 0.001 83 | -4.570 2E-4 | ||

| 5 | Modified enderson and pabis | a | 0.365 72 | 0.365 12 | 0.369 98 | 0.359 47 | 0.595 32 |

| k | 0.012 33 | 0.013 07 | 0.014 34 | 0.017 03 | 0.087 43 | ||

| b | 0.365 72 | 0.365 12 | 0.369 98 | 0.359 47 | 22.164 49 | ||

| g | 0.012 33 | 0.013 07 | 0.014 34 | 0.017 03 | 0.039 35 | ||

| c | 0.365 72 | 0.365 12 | 0.369 98 | 0.359 47 | -21.762 84 | ||

| h | 0.012 33 | 0.013 07 | 0.014 34 | 0.017 03 | 0.041 42 | ||

| 6 | Newton | k | 0.011 23 | 0.011 92 | 0.012 92 | 0.015 78 | 0.021 44 |

| 7 | Page | k | -0.105 99 | -0.109 21 | -0.113 68 | -0.125 64 | 0.0188 5 |

| n | -0.105 99 | -0.109 21 | -0.113 68 | -0.125 64 | 1.137 07 | ||

| 8 | Two-term Logarithmic model | a | 0.548 56 | 0.547 69 | 0.554 95 | 0.539 2 | -18.800 28 |

| K0 | 0.012 33 | 0.013 07 | 0.014 34 | 0.017 03 | 0.035 68 | ||

| b | 0.548 56 | 0.547 69 | 0.554 95 | 0.539 2 | 19.773 3 | ||

| K1 | 0.012 33 | 0.013 07 | 0.014 34 | 1.017 03 | 0.034 56 | ||

| 9 | Verma et al. | a | 1.118 35 | 1.117 63 | 1.138 21 | 1.103 26 | 55.232 05 |

| k | 0.012 57 | 0.013 34 | 0.014 7 | 0.017 43 | 0.033 94 | ||

| g | 15.304 4 | 15.714 88 | 15.856 79 | 16.038 18 | 0.034 28 | ||

| 10 | Wang and singh | a | -0.008 1 | -0.008 67 | -0.009 32 | -0.011 82 | -0.015 47 |

| b | 1.58878E-5 | 1.84101E-5 | 2.09099E-5 | 3.61915E-5 | 6.1261E-5 | ||

| 编号 No. | 模型名称 Name of model | SSE | R2 | RMSE |

|---|---|---|---|---|

| 1 | Weibull | 0.153 1 | 0.963 9 | 0.003 43 |

| 2 | Henderson and pabis | 0.107 3 | 0.974 6 | 0.002 403 |

| 3 | Logarithmic model | 0.007 7 | 0.998 1 | 0.000 535 626 |

| 4 | Midilli et al. | 0.055 4 | 0.979 6 | 0.035 4 |

| 5 | Modified enderson and pabis | 0.093 76 | 0.975 8 | 0.002 298 666 |

| 6 | Newton(single-term exponential) | 0.153 1 | 0.964 67 | 0.005 619 8 |

| 7 | Page | 0.153 06 | 0.963 86 | 0.003 682 6 |

| 8 | Two-term Logarithmic model | 0.094 8 | 0.976 66 | 0.002 224 8 |

| 9 | Verma et al. | 0.085 918 | 0.978 864 | 0.001 958 4 |

| 10 | Wang and singh | 0.010 839 6 | 0.997 265 3 | 0.001 276 6 |

Tab.5 The fitting results of 10 models at different temperatures

| 编号 No. | 模型名称 Name of model | SSE | R2 | RMSE |

|---|---|---|---|---|

| 1 | Weibull | 0.153 1 | 0.963 9 | 0.003 43 |

| 2 | Henderson and pabis | 0.107 3 | 0.974 6 | 0.002 403 |

| 3 | Logarithmic model | 0.007 7 | 0.998 1 | 0.000 535 626 |

| 4 | Midilli et al. | 0.055 4 | 0.979 6 | 0.035 4 |

| 5 | Modified enderson and pabis | 0.093 76 | 0.975 8 | 0.002 298 666 |

| 6 | Newton(single-term exponential) | 0.153 1 | 0.964 67 | 0.005 619 8 |

| 7 | Page | 0.153 06 | 0.963 86 | 0.003 682 6 |

| 8 | Two-term Logarithmic model | 0.094 8 | 0.976 66 | 0.002 224 8 |

| 9 | Verma et al. | 0.085 918 | 0.978 864 | 0.001 958 4 |

| 10 | Wang and singh | 0.010 839 6 | 0.997 265 3 | 0.001 276 6 |

| 模型参数 Parameters models | Logarithmic model | Wang and singh |

|---|---|---|

| Ranges of SSE | 0.003 7-0.013 3 | 0.002 21-0.020 9 |

| Mean value of SSE | 0.005 4 | 0.012 7 |

| Ranges of R2 | 0.999 3-0.996 9 | 0.993 2-0.999 3 |

| Mean value R2 | 0.998 1 | 0.997 3 |

| Ranges of RMSE | 0.001 8-0.008 1 | 0.005 8-0.019 2 |

| Mean value RMSE | 0.007 7 | 0.010 8 |

Tab.6 Results of two models under different drying conditions

| 模型参数 Parameters models | Logarithmic model | Wang and singh |

|---|---|---|

| Ranges of SSE | 0.003 7-0.013 3 | 0.002 21-0.020 9 |

| Mean value of SSE | 0.005 4 | 0.012 7 |

| Ranges of R2 | 0.999 3-0.996 9 | 0.993 2-0.999 3 |

| Mean value R2 | 0.998 1 | 0.997 3 |

| Ranges of RMSE | 0.001 8-0.008 1 | 0.005 8-0.019 2 |

| Mean value RMSE | 0.007 7 | 0.010 8 |

| 干燥温度 Drying temperature(℃) | 线性拟合方程 Linear fitting equation | R2 | Deff×10-9 (m2/s) | |

|---|---|---|---|---|

| 干燥温度 Drying temperature | 30 | Y =-0.076 7X + 0.613 9 | R2= 0.837 2 | 4.671 0 |

| 32.5 | Y =-0.079 2X +0.466 2 | R2= 0.913 1 | 4.823 3 | |

| 35 | Y =-0.087 6X + 0.614 5 | R2= 0.850 5 | 5.334 8 | |

| 37.5 | Y =-0.092 1X + 0.288 8 | R2= 0.962 5 | 5.608 8 | |

| 40 | Y =-0.114 4X + 0.415 5 | R2= 0.957 9 | 6.966 9 |

Tab.7 Effective moisture diffusivity of grape fruit during drying at different temperatures

| 干燥温度 Drying temperature(℃) | 线性拟合方程 Linear fitting equation | R2 | Deff×10-9 (m2/s) | |

|---|---|---|---|---|

| 干燥温度 Drying temperature | 30 | Y =-0.076 7X + 0.613 9 | R2= 0.837 2 | 4.671 0 |

| 32.5 | Y =-0.079 2X +0.466 2 | R2= 0.913 1 | 4.823 3 | |

| 35 | Y =-0.087 6X + 0.614 5 | R2= 0.850 5 | 5.334 8 | |

| 37.5 | Y =-0.092 1X + 0.288 8 | R2= 0.962 5 | 5.608 8 | |

| 40 | Y =-0.114 4X + 0.415 5 | R2= 0.957 9 | 6.966 9 |

| [1] | 马云龙, 张雯, 任艳君, 等. 葡萄干燥的研究进展[J]. 食品科技, 2022, 47(8):27-35. |

| MA Yunlong, ZHANG Wen, REN Yanjun, et al. Research progress on grape drying[J]. Food Science and Technology, 2022, 47(8):27-35. | |

| [2] | 侯旭杰, 张滨, 热衣木江, 等. 无核葡萄干护色保绿技术试验[J]. 塔里木农垦大学学报, 2000, 12(1):9-12. |

| HOU Xujie, ZHANG Bin, Reyimujiang, et al. Experiment on color protection and green preservation technology of seedless raisins[J]. Journal of Tarim Agricultural Reclamation University, 2000, 12(1):9-12. | |

| [3] |

康彦, 关志强, 李敏, 等. 预处理对无核白葡萄热风干燥特性的影响[J]. 食品科学, 2014, 35(5):119-123.

DOI |

|

KANG Yan, GUAN Zhiqiang, LI Min, et al. Effect of pretreatment on hot air drying characteristics of seedless white grapes[J]. Food Science, 2014, 35(5):119-123.

DOI |

|

| [4] | 孟阳, 刘峰娟, 王玉红, 等. 热风干燥温度对无核白葡萄干品质的影响[J]. 食品与机械, 2015, 31(1):204-207. |

| MENG Yang, LIU Fengjuan, WANG Yuhong, et al. Effect of hot air drying temperature on quality of seedless white raisins[J]. Food & Machinery, 2015, 31(1):204-207. | |

| [5] |

Wen X, Li W, Li W, et al. Quality characteristics and non-volatile taste formation mechanism of Lentinula edodes during hot air drying[J]. Food Chemistry, 2022, 393:133378.

DOI URL |

| [6] |

Pei Y S, Li Z F, Song C F, et al. Analysis and modelling of temperature and moisture gradient for ginger slices in hot air drying[J]. Journal of Food Engineering, 2022, 323:111009.

DOI URL |

| [7] |

Shi S, Feng J, An G E, et al. Dynamics of heat transfer and moisture in beef jerky during hot air drying[J]. Meat Science, 2021, 182:108638.

DOI URL |

| [8] |

Gao M Q, Wan K J, Miao Z Y, et al. Hot-air drying shrinkage process of lignite and its cracking mechanism[J]. Fuel, 2022, 316:123187.

DOI URL |

| [9] | 刘辉, 卢扬, 叶夕苗, 等. 外源硫诱导苦荞镉胁迫响应的比较转录组学分析[J]. 生物技术通报, 2023:1-15. |

| LIU Hui, LU Yang, YE Ximiao, et al. Comparative transcriptomic analysis of exogenous sulfur-induced cadmium stress response of buckwheat buckwheat[J]. Biotechnology Bulletin, 2023:1-15. | |

| [10] |

Xiao H W, Bai J W, Xie L, et al. Thin-layer air impingement drying enhances drying rate of American ginseng(Panax quinquefolium L.) slices with quality attributes considered[J]. Food and Bioproducts Processing, 2015, 94:581-591.

DOI URL |

| [11] |

Peter M, Liu Z W, Fang Y L, et al. Computational intelligence and mathematical modelling in chanterelle mushrooms’ drying process under heat pump dryer[J]. Biosystems Engineering, 2021, 212:143-159.

DOI URL |

| [12] | Niu Y, Wei S Y, Liu H, et al. The kinetics of nutritional quality changes during winter jujube slices drying process[J]. Quality Assurance and Safety of Crops & Foods, 2021, 13(1):73-82. |

| [13] |

Ortiz-RodrÍguez N M, MarÍn-Camacho J F, Llamas-Gonzalez A, et al. Drying kinetics of natural rubber sheets under two solar thermal drying systems[J]. Renewable Energy, 2021, 165:438-454.

DOI URL |

| [14] | Biswas R, Hossain M A, Zzaman W. Thin layer modeling of drying kinetics, rehydration kinetics and color changes of osmotic pre-treated pineapple(Ananas comosus)slices during drying:Development of a mechanistic model for mass transfer[J]. Innovative Food Science & Emerging Technologies, 2022, 80:103094. |

| [15] |

Masud M H, Himel H H, Arefin A M E, et al. Mathematical modelling and exergo-environmental analysis of drying potato samples in a waste heat-based convective dryer[J]. Environmental Challenges, 2021, 5:100372.

DOI URL |

| [16] | Bousselma A, Abdessemed D, Tahraoui H, et al. Artificial intelligence and mathematical modelling of the drying kinetics of pre-treated whole apricots[J]. Croatian Society of Chemical Engineers/HDKI, 2021(11112). |

| [17] |

El-Mesery H S, Sarpong F, Xu W X, et al. Design of low-energy consumption hybrid dryer:A case study of garlic(Allium sativum)drying process[J]. Case Studies in Thermal Engineering, 2022, 33:101929.

DOI URL |

| [18] |

Meng Z F, Cui X N, Zhang H, et al. Study on drying characteristics of yam slices under heat pump-electrohydrodynamics combined drying[J]. Case Studies in Thermal Engineering, 2023, 41:102601.

DOI URL |

| [19] |

Mbegbu N N, Nwajinka C O, Amaefule D O. Thin layer drying models and characteristics of scent leaves(Ocimum gratissimum)and lemon basil leaves(Ocimum africanum)[J]. Heliyon, 2021, 7(1):e05945.

DOI URL |

| [20] |

Nanvakenari S, Movagharnejad K, Latifi A. Modelling and experimental analysis of rice drying in new fluidized bed assisted hybrid infrared-microwave dryer[J]. Food Research International, 2022, 159:111617.

DOI URL |

| [21] |

Lamrani B, Elmrabet Y, Mathew I, et al. Energy, economic analysis and mathematical modelling of mixed-mode solar drying of potato slices with thermal storage loaded V-groove collector:application to Maghreb Region[J]. Renewable Energy, 2022, 200:48-58.

DOI URL |

| [22] |

Sitorus A, Novrinaldi, Putra S A, et al. Modelling drying kinetics of paddy in swirling fluidized bed dryer[J]. Case Studies in Thermal Engineering, 2021, 28:101572.

DOI URL |

| [23] | 董艳华. 无核白葡萄干燥过程特性及其变色机理研究[D]. 青岛: 中国海洋大学, 2015. |

| DONG Yanhua. Study on drying process characteristics and discoloration mechanism of seedless white grapes[D]. Qingdao: Ocean University of China, 2015. | |

| [24] | 叶令帅, 索玉静, 韩卫娟, 等. 早熟柿与晚熟柿在果实发育过程中的品质特性差异[J]. 西北农林科技大学学报(自然科学版), 2023, 51(7):83-91,106. |

| YE Lingshuai, SUO Yujing, HAN Weijuan, et al. Differences in quality characteristics between early and late ripening persimmons during fruit development[J]. Journal of Northwest A&F University(Natural Science Edition.), 2023, 51(7):83-91,106. | |

| [25] | 代羽可欣, 王宇滨, 赵文婷, 等. 热处理对鲜切马铃薯褐变及挥发性物质的影响[J]. 现代食品科技, 2022:1-8. |

| DAIYU Kexin, WANG Yubin, ZHAO Wenting, et al. Effects of heat treatment on browning and volatile substances in fresh-cut potato[J]. Modern Food Science and Technology, 2022:1-8. | |

| [26] | 黄健航, 郑峻, 杨斌, 等. 不同干燥温度对鹿茸菇品质及其抗氧化活性的比较分析[J]. 中国食品添加剂, 2022, 33(2):194-200. |

| HUANG Jianhang, ZHENG Jun, YANG Bin, et al. Comparative analysis of quality and antioxidant activity of deer antler mushroom at different drying temperatures[J]. China Food Additives, 2022, 33(2):194-200. |

| [1] | QIAO Yajie, FU Huixin, QIAO Xue, MENG Xintao, ZHANG Ting, PAN Yan. Study on the variation of fresh beef quality under different storage temperature conditions [J]. Xinjiang Agricultural Sciences, 2024, 61(9): 2323-2329. |

| [2] | HU Huabing, SUN Linlin, LIU Jianxiong, HE Biwei, LIU Xun, HUAN Tin, LI Youfang. Correlation analysis of sugar accumulation and temperature in sugar beet under drip irrigation [J]. Xinjiang Agricultural Sciences, 2024, 61(8): 1916-1925. |

| [3] | YAO Qing, WANG Jiehua, Xiernayi Abudula, Dilimulati Tulahong, CUI Hongliang. Physiological responses of different quinoa varieties during seedling stage under low temperature stress [J]. Xinjiang Agricultural Sciences, 2024, 61(7): 1597-1604. |

| [4] | FU Xinfa, LYU Tingbo, WANG Jiulong, LI Gangqiang, SONG Renyou, LIU Yifan. Effect of spring irrigation quota on water temperature and salt distribution in cotton fields and seedling growth of cotton [J]. Xinjiang Agricultural Sciences, 2024, 61(6): 1336-1344. |

| [5] | QIANG Lidong, FENG Kuan, ZHU Changan, ZHAO Yun, LI Zhaofeng, LI Weihua. Effect of high temperature stress at anthesis on seed vigor of wheat [J]. Xinjiang Agricultural Sciences, 2024, 61(6): 1345-1351. |

| [6] | YANG Junyan, YAN Miao, WU Haibo, YANG Wenli, WANG Haojie, MAO Jiancai, ZHAI Wenqiang, LI Junhua. The impact of high temperature on different thick -skinned melon varieties and comprehensive evaluation of its heat resistance [J]. Xinjiang Agricultural Sciences, 2024, 61(6): 1386-1396. |

| [7] | DANG Xuwei, LIN Xinyuan, HE Zheng, CHEN Yan, CI Baoxia, MA Xuehua, GUO Chenli, HE Yaxing, LIU Yang, MA Fuyu. Extraction and accuracy evaluation of cotton canopy temperature under drip irrigation based on uav thermal infrared remote sensing [J]. Xinjiang Agricultural Sciences, 2024, 61(3): 565-575. |

| [8] | LU Hongqin, BAI Yungang, CHAI Zhongping, LU Zhenlin, LIU Hongbo, ZHENG Ming, XIAO Jun. Research on the effect of "dry sowing and wet discharge" cotton field seedling preservation technology in an arched shed environment [J]. Xinjiang Agricultural Sciences, 2024, 61(12): 2872-2882. |

| [9] | ZHOU Xiaoyun, ZHANG Jungao, LIANG Jing, GONG Jingyun, ZHOU Guangwei, ZHANG Shaomin, LEI Bin. Effects of the carboxin from seed coating formulation on the cotton seed germination and seedling agronomic characteristics under water and temperature stress [J]. Xinjiang Agricultural Sciences, 2024, 61(12): 3051-3060. |

| [10] | DANG Xinchen, SHEN Zongyi, QU Donglin, SONG Yuyang. Effects of different agronomic measures on leaf curtain microclimate of Chardonnay grape [J]. Xinjiang Agricultural Sciences, 2024, 61(10): 2427-2433. |

| [11] | LI Xinyu, Kainaisi Habijiang, LI Changcheng, ZHAO Lei, ZHANG Zhigang, ZHAO Shirong. Analyze on the quality change rule of different degree of ripeness apricot fruit under normal temperature storage conditions [J]. Xinjiang Agricultural Sciences, 2024, 61(10): 2444-2457. |

| [12] | ZHOU Xiaoyun, LEI Bin, ZHANG Jungao, LIANG Jing, GONG Jingyun, ZHOU Guangwei, ZHANG Shaomin, LI Jin. Comparative analysis of physiological and biochemical characteristics of cold tolerance of cotton seedlings coated with 7.2% carboxin and 40% amicarthiazol [J]. Xinjiang Agricultural Sciences, 2024, 61(1): 176-183. |

| [13] | LIU Haijun, ZHANG Hao, WANG Yifan, CHEN Maoguang, WU Fengquan, LIN Tao, TANG Qiuxiang. Effects of different mulching materials and irrigation on yield formation and effective accumulated temperature production efficiency of machine-picked cotton [J]. Xinjiang Agricultural Sciences, 2023, 60(9): 2091-2100. |

| [14] | WANG Hui, GUO Jincheng, SONG Jia, ZHANG Tingjun, He Liangrong. Physiological and biochemical analysis of transgenic offspring of upland cotton GhCIPK6 under high temperature Stress [J]. Xinjiang Agricultural Sciences, 2023, 60(9): 2109-2119. |

| [15] | LIU Yufang, ZHANG Zhigang, LI Changcheng, LI Hong, CHENG Ping, YANG Lu. Effects of different temperature and maturity on rot rate and quality of apricot during storage [J]. Xinjiang Agricultural Sciences, 2023, 60(9): 2189-2197. |

| Viewed | ||||||||||||||||||||||||||||||||||||||||||||||||||

|

Full text 62

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Abstract 176

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||