Xinjiang Agricultural Sciences ›› 2025, Vol. 62 ›› Issue (4): 944-953.DOI: 10.6048/j.issn.1001-4330.2025.04.019

• Horticultural Special Local Products · Forestry · Agricultural Product Processing Engineering • Previous Articles Next Articles

CAI Chenyang1,2( ), GUO Limin2,3(

), GUO Limin2,3( ), WU Bin2,3

), WU Bin2,3

Received:2024-09-20

Online:2025-04-20

Published:2025-06-20

Supported by:通讯作者:

过利敏(1979-),女,新疆伊犁人,副研究员,博士,硕士生导师,研究方向为农产品深加工与功能营养评价,(E-mail) guolm_xj@163.com

作者简介:蔡晨阳(1999-),男,陕西宝鸡人,硕士,研究方向为食品加工与安全,(E-mail)chenyang.cain@outlook.com

基金资助:CLC Number:

CAI Chenyang, GUO Limin, WU Bin. Process optimization of tomato and carrot mixed juice prepared by compound enzyme[J]. Xinjiang Agricultural Sciences, 2025, 62(4): 944-953.

蔡晨阳, 过利敏, 吴斌. 复合酶制备番茄胡萝卜混合果汁的工艺优化[J]. 新疆农业科学, 2025, 62(4): 944-953.

Add to citation manager EndNote|Ris|BibTeX

URL: https://www.xjnykx.com/EN/10.6048/j.issn.1001-4330.2025.04.019

| 编码值 Coded value | 因素Factors | |||

|---|---|---|---|---|

| A酶解 比例 | B加酶量 (g/L) | C酶解时间 (min) | D酶解温度 (℃) | |

| -1 | 1∶1 | 18 | 30 | 40 |

| 0 | 1∶2 | 24 | 60 | 45 |

| 1 | 1∶3 | 30 | 90 | 50 |

Tab.1 Box-Behnken experimental design factor level

| 编码值 Coded value | 因素Factors | |||

|---|---|---|---|---|

| A酶解 比例 | B加酶量 (g/L) | C酶解时间 (min) | D酶解温度 (℃) | |

| -1 | 1∶1 | 18 | 30 | 40 |

| 0 | 1∶2 | 24 | 60 | 45 |

| 1 | 1∶3 | 30 | 90 | 50 |

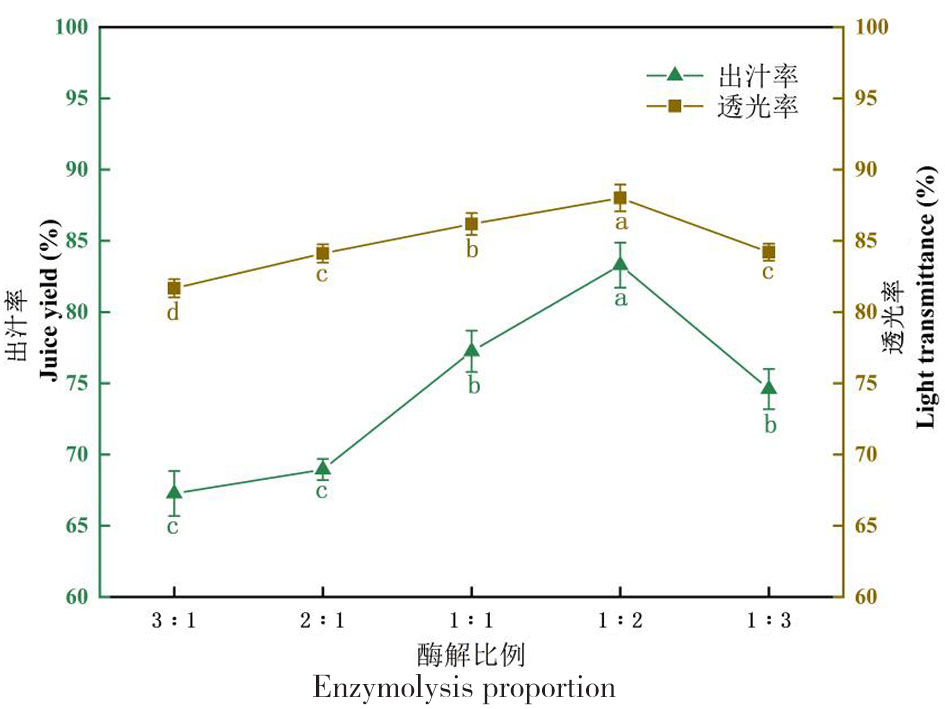

Fig.1 Changes of juice yield and light transmittance under different compound enzyme ratios Notes:Different lowercase letters indicate significant differences within the group(P<0.05), the same lowercase letters indicate no significant differences within the group(P>0.05),the same as below

| 试验号 Test number | A酶比例 Enzyme ratio | B酶添加量 Enzyme addition amount | C酶解时间 Enzymatic hydrolysis time | D酶解温度 Enzymatic hydrolysis temperature | 出汁率 Juice Yield (%) | 透光率 Transmittancy (%) |

|---|---|---|---|---|---|---|

| 1 | -1 | -1 | 0 | 0 | 81.66 | 88.2 |

| 2 | 1 | -1 | 0 | 0 | 82.98 | 90.67 |

| 3 | -1 | 1 | 0 | 0 | 84.23 | 89.36 |

| 4 | 1 | 1 | 0 | 0 | 81.57 | 89.08 |

| 5 | 0 | 0 | -1 | -1 | 79.38 | 93.5 |

| 6 | 0 | 0 | 1 | -1 | 79.47 | 85.37 |

| 7 | 0 | 0 | -1 | 1 | 76.43 | 87.56 |

| 8 | 0 | 0 | 1 | 1 | 78.24 | 94.47 |

| 9 | -1 | 0 | 0 | -1 | 80.96 | 87.09 |

| 10 | 1 | 0 | 0 | -1 | 82.06 | 87.26 |

| 11 | -1 | 0 | 0 | 1 | 80.61 | 88.2 |

| 12 | 1 | 0 | 0 | 1 | 79.14 | 87.89 |

| 13 | 0 | -1 | -1 | 0 | 78.48 | 91.65 |

| 14 | 0 | 1 | -1 | 0 | 79.95 | 91.76 |

| 15 | 0 | -1 | 1 | 0 | 81.14 | 92.78 |

| 16 | 0 | 1 | 1 | 0 | 81.73 | 92.18 |

| 17 | -1 | 0 | -1 | 0 | 80.73 | 90.64 |

| 18 | 1 | 0 | -1 | 0 | 80.11 | 89.29 |

| 19 | -1 | 0 | 1 | 0 | 81.16 | 90.23 |

| 20 | 1 | 0 | 1 | 0 | 83.29 | 89.73 |

| 21 | 0 | -1 | 0 | -1 | 80.21 | 88.71 |

| 22 | 0 | 1 | 0 | -1 | 80.89 | 89.63 |

| 23 | 0 | -1 | 0 | 1 | 77.85 | 91.41 |

| 24 | 0 | 1 | 0 | 1 | 80.21 | 91.27 |

| 25 | 0 | 0 | 0 | 0 | 84.25 | 95.97 |

| 26 | 0 | 0 | 0 | 0 | 84.68 | 95.38 |

| 27 | 0 | 0 | 0 | 0 | 84.82 | 94.94 |

| 28 | 0 | 0 | 0 | 0 | 85.23 | 93.89 |

| 29 | 0 | 0 | 0 | 0 | 85.01 | 95.45 |

Tab.2 Box-Behnken Design Experimental Design and Results

| 试验号 Test number | A酶比例 Enzyme ratio | B酶添加量 Enzyme addition amount | C酶解时间 Enzymatic hydrolysis time | D酶解温度 Enzymatic hydrolysis temperature | 出汁率 Juice Yield (%) | 透光率 Transmittancy (%) |

|---|---|---|---|---|---|---|

| 1 | -1 | -1 | 0 | 0 | 81.66 | 88.2 |

| 2 | 1 | -1 | 0 | 0 | 82.98 | 90.67 |

| 3 | -1 | 1 | 0 | 0 | 84.23 | 89.36 |

| 4 | 1 | 1 | 0 | 0 | 81.57 | 89.08 |

| 5 | 0 | 0 | -1 | -1 | 79.38 | 93.5 |

| 6 | 0 | 0 | 1 | -1 | 79.47 | 85.37 |

| 7 | 0 | 0 | -1 | 1 | 76.43 | 87.56 |

| 8 | 0 | 0 | 1 | 1 | 78.24 | 94.47 |

| 9 | -1 | 0 | 0 | -1 | 80.96 | 87.09 |

| 10 | 1 | 0 | 0 | -1 | 82.06 | 87.26 |

| 11 | -1 | 0 | 0 | 1 | 80.61 | 88.2 |

| 12 | 1 | 0 | 0 | 1 | 79.14 | 87.89 |

| 13 | 0 | -1 | -1 | 0 | 78.48 | 91.65 |

| 14 | 0 | 1 | -1 | 0 | 79.95 | 91.76 |

| 15 | 0 | -1 | 1 | 0 | 81.14 | 92.78 |

| 16 | 0 | 1 | 1 | 0 | 81.73 | 92.18 |

| 17 | -1 | 0 | -1 | 0 | 80.73 | 90.64 |

| 18 | 1 | 0 | -1 | 0 | 80.11 | 89.29 |

| 19 | -1 | 0 | 1 | 0 | 81.16 | 90.23 |

| 20 | 1 | 0 | 1 | 0 | 83.29 | 89.73 |

| 21 | 0 | -1 | 0 | -1 | 80.21 | 88.71 |

| 22 | 0 | 1 | 0 | -1 | 80.89 | 89.63 |

| 23 | 0 | -1 | 0 | 1 | 77.85 | 91.41 |

| 24 | 0 | 1 | 0 | 1 | 80.21 | 91.27 |

| 25 | 0 | 0 | 0 | 0 | 84.25 | 95.97 |

| 26 | 0 | 0 | 0 | 0 | 84.68 | 95.38 |

| 27 | 0 | 0 | 0 | 0 | 84.82 | 94.94 |

| 28 | 0 | 0 | 0 | 0 | 85.23 | 93.89 |

| 29 | 0 | 0 | 0 | 0 | 85.01 | 95.45 |

| 方差来源 Source of variance | 平方和 Sum of squares | 自由度 Df | 均方和 Mean square | F值 F value | P值 P value | 显著性 Significance |

|---|---|---|---|---|---|---|

| 模型Model | 145.74 | 14 | 10.41 | 50.82 | <0.000 1 | ** |

| A | 3.333E-003 | 1 | 3.333E-003 | 0.016 | 0.900 3 | ns |

| B | 2.78 | 1 | 2.78 | 13.59 | 0.024 | * |

| C | 8.25 | 1 | 8.25 | 40.28 | <0.000 1 | ** |

| D | 10.03 | 1 | 10.03 | 48.96 | <0.000 1 | ** |

| AB | 3.96 | 1 | 3.96 | 19.33 | 0.000 6 | * |

| AC | 1.89 | 1 | 1.89 | 9.23 | 0.008 9 | * |

| AD | 1.65 | 1 | 1.65 | 8.06 | 0.013 1 | * |

| BC | 0.19 | 1 | 0.19 | 0.95 | 0.347 4 | ns |

| BD | 1.17 | 1 | 1.17 | 5.69 | 0.031 7 | * |

| CD | 0.74 | 1 | 0.74 | 3.61 | 0.078 2 | ns |

| A2 | 2.55 | 1 | 2.55 | 12.43 | 0.003 4 | ** |

| B2 | 14.92 | 1 | 14.92 | 72.83 | <0.000 1 | ** |

| C2 | 55.51 | 1 | 55.51 | 270.99 | <0.000 1 | ** |

| D2 | 77.10 | 1 | 77.10 | 376.45 | <0.000 1 | ** |

| 残差Residual | 2.87 | 14 | 0.20 | |||

| 失拟Lack of fit | 2.32 | 10 | 0.23 | 1.70 | 0.321 3 | ns |

| 纯误差Pure error | 0.55 | 4 | 0.14 | |||

| 总误差Total error | 148.60 | 28 | ||||

| R2=0.980 7 |

Tab.3 Variance of juice yield regression model

| 方差来源 Source of variance | 平方和 Sum of squares | 自由度 Df | 均方和 Mean square | F值 F value | P值 P value | 显著性 Significance |

|---|---|---|---|---|---|---|

| 模型Model | 145.74 | 14 | 10.41 | 50.82 | <0.000 1 | ** |

| A | 3.333E-003 | 1 | 3.333E-003 | 0.016 | 0.900 3 | ns |

| B | 2.78 | 1 | 2.78 | 13.59 | 0.024 | * |

| C | 8.25 | 1 | 8.25 | 40.28 | <0.000 1 | ** |

| D | 10.03 | 1 | 10.03 | 48.96 | <0.000 1 | ** |

| AB | 3.96 | 1 | 3.96 | 19.33 | 0.000 6 | * |

| AC | 1.89 | 1 | 1.89 | 9.23 | 0.008 9 | * |

| AD | 1.65 | 1 | 1.65 | 8.06 | 0.013 1 | * |

| BC | 0.19 | 1 | 0.19 | 0.95 | 0.347 4 | ns |

| BD | 1.17 | 1 | 1.17 | 5.69 | 0.031 7 | * |

| CD | 0.74 | 1 | 0.74 | 3.61 | 0.078 2 | ns |

| A2 | 2.55 | 1 | 2.55 | 12.43 | 0.003 4 | ** |

| B2 | 14.92 | 1 | 14.92 | 72.83 | <0.000 1 | ** |

| C2 | 55.51 | 1 | 55.51 | 270.99 | <0.000 1 | ** |

| D2 | 77.10 | 1 | 77.10 | 376.45 | <0.000 1 | ** |

| 残差Residual | 2.87 | 14 | 0.20 | |||

| 失拟Lack of fit | 2.32 | 10 | 0.23 | 1.70 | 0.321 3 | ns |

| 纯误差Pure error | 0.55 | 4 | 0.14 | |||

| 总误差Total error | 148.60 | 28 | ||||

| R2=0.980 7 |

| 方差来源 Source of variance | 平方和 Sum of squares | 自由度 Df | 均方和 Mean square | F值 F value | P值 P value | 显著性 Significance |

|---|---|---|---|---|---|---|

| 模型Model | 220.59 | 14 | 15.76 | 31.2 | <0.000 1 | ** |

| A | 3.33E-03 | 1 | 3.33E-03 | 6.60E-03 | 0.936 4 | ns |

| B | 1.63E-03 | 1 | 1.63E-03 | 3.24E-03 | 0.955 4 | ns |

| C | 0.011 | 1 | 0.011 | 0.021 | 0.885 8 | ns |

| D | 7.11 | 1 | 7.11 | 14.09 | 0.002 1 | * |

| AB | 1.89 | 1 | 1.89 | 3.74 | 0.073 5 | ns |

| AC | 0.18 | 1 | 0.18 | 0.36 | 0.559 3 | ns |

| AD | 0.058 | 1 | 0.058 | 0.11 | 0.740 6 | ns |

| BC | 0.13 | 1 | 0.13 | 0.25 | 0.625 1 | ns |

| BD | 0.28 | 1 | 0.28 | 0.56 | 0.468 1 | ns |

| CD | 56.55 | 1 | 56.55 | 112 | <0.000 1 | ** |

| A2 | 104.92 | 1 | 104.92 | 207.78 | <0.000 1 | ** |

| B2 | 17.43 | 1 | 17.43 | 34.52 | <0.000 1 | ** |

| C2 | 11.5 | 1 | 11.5 | 22.78 | 0.000 3 | ** |

| D2 | 76.39 | 1 | 76.39 | 151.29 | <0.000 1 | ** |

| 残差Residual | 7.07 | 14 | 0.5 | |||

| 失拟Lack of fit | 4.62 | 10 | 0.46 | 0.76 | 0.672 9 | ns |

| 纯误差Pure error | 2.44 | 4 | 0.61 | |||

| 总误差Total error | 227.66 | 28 | ||||

| R2=0.968 9 |

Tab.4 Light transmittance regression model variance

| 方差来源 Source of variance | 平方和 Sum of squares | 自由度 Df | 均方和 Mean square | F值 F value | P值 P value | 显著性 Significance |

|---|---|---|---|---|---|---|

| 模型Model | 220.59 | 14 | 15.76 | 31.2 | <0.000 1 | ** |

| A | 3.33E-03 | 1 | 3.33E-03 | 6.60E-03 | 0.936 4 | ns |

| B | 1.63E-03 | 1 | 1.63E-03 | 3.24E-03 | 0.955 4 | ns |

| C | 0.011 | 1 | 0.011 | 0.021 | 0.885 8 | ns |

| D | 7.11 | 1 | 7.11 | 14.09 | 0.002 1 | * |

| AB | 1.89 | 1 | 1.89 | 3.74 | 0.073 5 | ns |

| AC | 0.18 | 1 | 0.18 | 0.36 | 0.559 3 | ns |

| AD | 0.058 | 1 | 0.058 | 0.11 | 0.740 6 | ns |

| BC | 0.13 | 1 | 0.13 | 0.25 | 0.625 1 | ns |

| BD | 0.28 | 1 | 0.28 | 0.56 | 0.468 1 | ns |

| CD | 56.55 | 1 | 56.55 | 112 | <0.000 1 | ** |

| A2 | 104.92 | 1 | 104.92 | 207.78 | <0.000 1 | ** |

| B2 | 17.43 | 1 | 17.43 | 34.52 | <0.000 1 | ** |

| C2 | 11.5 | 1 | 11.5 | 22.78 | 0.000 3 | ** |

| D2 | 76.39 | 1 | 76.39 | 151.29 | <0.000 1 | ** |

| 残差Residual | 7.07 | 14 | 0.5 | |||

| 失拟Lack of fit | 4.62 | 10 | 0.46 | 0.76 | 0.672 9 | ns |

| 纯误差Pure error | 2.44 | 4 | 0.61 | |||

| 总误差Total error | 227.66 | 28 | ||||

| R2=0.968 9 |

| 项目 Items | 总酚 Total phenols (μg GAE/mL) | β-胡萝卜素 β-carotene (μg/g) | 可溶性固形物 TSS(%) | DPPH自由基清除率 Scavenging rate of DPPH radical (%) | ABTS自由基 清除率 Scavenging rate of ABTS radical (%) |

|---|---|---|---|---|---|

| 酶解前Before enzymatic hydrolysis | 40.21b | 154.30a | 10.8a | 53.07a | 36.79b |

| 酶解后After enzymatic hydrolysis | 125.41a | 136.22a | 10.5a | 51.81a | 42.82a |

Tab.5 Changes in total phenolic content and β -carotene content in the mixed fruit pulp before and after enzymatic digestion

| 项目 Items | 总酚 Total phenols (μg GAE/mL) | β-胡萝卜素 β-carotene (μg/g) | 可溶性固形物 TSS(%) | DPPH自由基清除率 Scavenging rate of DPPH radical (%) | ABTS自由基 清除率 Scavenging rate of ABTS radical (%) |

|---|---|---|---|---|---|

| 酶解前Before enzymatic hydrolysis | 40.21b | 154.30a | 10.8a | 53.07a | 36.79b |

| 酶解后After enzymatic hydrolysis | 125.41a | 136.22a | 10.5a | 51.81a | 42.82a |

| [1] | 尚天翠. 黄瓜、胡萝卜、番茄复合饮料的研制[J]. 安徽农学通报, 2019, 25(20): 130-131. |

| SHANG Tiancui. Development of compound beverage of cucumber, carrot and tomato[J]. Anhui Agricultural Science Bulletin, 2019, 25(20): 130-131. | |

| [2] | 赵能. NFC胡萝卜汁关键技术及其体外抗氧化活性研究[D]. 杨凌: 西北农林科技大学, 2015. |

| ZHAO Neng. Key Technologies of NFC Carrot Juice and The Assessment of Antioxidant Capacity in Vitro[D]. Yangling: Northwest A & F University, 2015. | |

| [3] | 隋明, 朱克永, 胡继红. 苹果-番茄-胡萝卜复合果蔬汁饮料营养研究[J]. 江苏调味副食品, 2018, 35(1): 1-3, 9. |

| SUI Ming, ZHU Keyong, HU Jihong. On the nutrition of apple-tomatoes-carrot compound juice[J]. Jiangsu Condiment and Subsidiary Food, 2018, 35(1): 1-3, 9. | |

| [4] | 张芳, 邢霄龙. 胡萝卜-柚复合果蔬饮料的研制[J]. 饮料工业, 2020, 23(6): 31-35. |

| ZHANG Fang, XING Xiaolong. Development of natural compound fruit and vegetable beverage of carrot and pomelo[J]. Beverage Industry, 2020, 23(6): 31-35. | |

| [5] | Sluijs I, Beulens J W J, Grobbee D E, et al. Dietary carotenoid intake is associated with lower prevalence of metabolic syndrome in middle-aged and elderly men[J]. The Journal of Nutrition, 2009, 139(5): 987-992. |

| [6] | 卢薇, 鲁江. 高压均质灭菌对胡萝卜橙汁理化性质及类胡萝卜素生物利用率的影响[J]. 食品安全质量检测学报, 2023, 14(6): 295-301. |

| LU Wei, LU Jiang. Effects of high-pressure homogenization sterilization on physicochemical properties and carotenoid bioaccessibility of carrot-orange juices[J]. Journal of Food Safety & Quality, 2023, 14(6): 295-301. | |

| [7] | 孙英, 廖小军, 胡小松. 加工单元操作对胡萝卜汁理化指标和果肉颗粒大小的影响[J]. 食品与发酵工业, 2004, 30(5): 14-17. |

| SUN Ying, LIAO Xiaojun, HU Xiaosong. Effect of unit operations on physical and chemical parameters and pulp particle size of carrot juice[J]. Food and Fermentation Industries, 2004, 30(5): 14-17. | |

| [8] | 李远蓬, 朱棚伟, 何慧, 等. 果胶酶与半纤维素酶复合酶解制备费约果果汁的工艺优化[J]. 食品工业科技, 2024, 45(3): 179-186. |

| LI Yuanpeng, ZHU Pengwei, HE Hui, et al. Optimization of pectinase and hemicellulase complex enzymatic hydrolysis for the preparation of Feijoa fruit juice[J]. Science and Technology of Food Industry, 2024, 45(3): 179-186. | |

| [9] | 张程慧, 石超, 冯叙桥. 胡萝卜、番茄、黄瓜和西芹制汁过程中酶解工艺的优化[J]. 食品工业科技, 2020, 41(21): 199-207. |

| ZHANG Chenghui, SHI Chao, FENG Xuqiao. Optimization of enzymatic hydrolysis on vegetable juice of carrot, tomato, cucumber and celery[J]. Science and Technology of Food Industry, 2020, 41(21): 199-207. | |

| [10] |

Toushik S H, Lee K T, Lee J S, et al. Functional applications of lignocellulolytic enzymes in the fruit and vegetable processing industries[J]. Journal of Food Science, 2017, 82(3): 585-593.

DOI PMID |

| [11] | Toy J Y H, Lu Y Y, Huang D J, et al. Enzymatic treatment, unfermented and fermented fruit-based products: current state of knowledge[J]. Critical Reviews in Food Science and Nutrition, 2022, 62(7): 1890-1911. |

| [12] |

Catalkaya G, Kahveci D. Optimization of enzyme assisted extraction of lycopene from industrial tomato waste[J]. Separation and Purification Technology, 2019, 219: 55-63.

DOI |

| [13] | Ribas-Agustí A, Van Buggenhout S, Palmero P, et al. Investigating the role of pectin in carrot cell wall changes during thermal processing: a microscopic approach[J]. Innovative Food Science & Emerging Technologies, 2014, 24: 113-120. |

| [14] | 陈铭中, 钟旭美, 孔令开, 等. 香蕉芒果复合果浆酶解工艺的优化[J]. 农产品加工, 2022,(8): 30-33. |

| CHEN Mingzhong, ZHONG Xumei, KONG Lingkai, et al. Optimization of enzymatic hydrolysis of banana and mango complex pulp[J]. Farm Products Processing, 2022,(8): 30-33. | |

| [15] |

Suárez-Jacobo Á, Rüfer C E, Gervilla R, et al. Influence of ultra-high pressure homogenisation on antioxidant capacity, polyphenol and vitamin content of clear apple juice[J]. Food Chemistry, 2011, 127(2): 447-454.

DOI PMID |

| [16] | Knockaert G, Lemmens L, Van Buggenhout S, et al. Changes in β-carotene bioaccessibility and concentration during processing of carrot puree[J]. Food Chemistry, 2012, 133(1): 60-67. |

| [17] | Xu X B, Guo S W, Hao X H, et al. Improving antioxidant and antiproliferative activities of Colla corii asini hydrolysates using Ginkgo biloba extracts[J]. Food Science & Nutrition, 2018, 6(4): 765-772. |

| [18] | 任旭桐, 崔振华, 邱佳, 等. 复合酶对枸杞果汁出汁率的影响[J]. 安徽农业科学, 2019, 47(22): 175-177, 192. |

| REN Xutong, CUI Zhenhua, QIU Jia, et al. Effect of compound enzymes on juice yield of Lycium chinense juice[J]. Journal of Anhui Agricultural Sciences, 2019, 47(22): 175-177, 192. | |

| [19] | Ma T T, Luo J Y, Tian C R, et al. Influence of enzyme liquefaction treatment on major carotenoids of carrot (Daucus carrot l.) juice[J]. Journal of Food Processing and Preservation, 2016, 40(6): 1370-1382. |

| [20] | Lopez-Sanchez P, Martinez-Sanz M, Bonilla M R, et al. Nanostructure and poroviscoelasticity in cell wall materials from onion, carrot and apple: roles of pectin[J]. Food Hydrocolloids, 2020, 98: 105253. |

| [21] | Sadhu S. Cellulase production by bacteria: a review[J]. British Microbiology Research Journal, 2013, 3(3): 235-258. |

| [22] | 唐杰, 零东宁, 李丽, 等. 果胶酶酶解桑葚和杨梅果汁工艺研究[J]. 轻工科技, 2020, 36(8): 21-23, 51. |

| TANG Jie, LING Dongning, LI Li, et al. Study on enzymatic hydrolysis of mulberry and bayberry juice by pectinase[J]. Light Industry Science and Technology, 2020, 36(8): 21-23, 51. | |

| [23] |

Raveendran S, Parameswaran B, Ummalyma S B, et al. Applications of microbial enzymes in food industry[J]. Food Technology and Biotechnology, 2018, 56(1): 16-30.

DOI PMID |

| [24] | Akesowan A, Choonhahirun A. Effect of enzyme treatment on guava juice production using response surface methodology[J]. Journal of Animal and Plant Sciences, 2013, 23: 114-120. |

| [25] | Siddiq M, Dolan K D, Perkins-Veazie P, et al. Effect of pectinolytic and cellulytic enzymes on the physical, chemical, and antioxidant properties of blueberry (Vaccinium corymbosum L.) juice[J]. LWT, 2018, 92: 127-132. |

| [1] | Yelesheng Tohedabuick, TU Zhendong, LI Binbin, Nadila Waili, CHEN Ziyun, LI Xuewen. Optimization of Enzymolysis of Sweet Sorghum Juice by Response Surface Methodology [J]. Xinjiang Agricultural Sciences, 2022, 59(7): 1632-1641. |

| [2] | HU Hai-fang;WANG Jing;LIU Fen-lan;JIA Huan-ting;YANG Yang;ZHANG Dong-ya. The Research on Optimized Process of Producing Crabapple Juice with Pectinase [J]. , 2013, 50(9): 1662-1667. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||