新疆农业科学 ›› 2024, Vol. 61 ›› Issue (1): 217-229.DOI: 10.6048/j.issn.1001-4330.2024.01.024

王善博1( ), 阿力木·买买提吐尔逊1,2(

), 阿力木·买买提吐尔逊1,2( ), 李谦绪2, 杜志高2, 张伟1

), 李谦绪2, 杜志高2, 张伟1

收稿日期:2023-05-18

出版日期:2024-01-20

发布日期:2024-02-21

通信作者:

阿力木·买买提吐尔逊(1973-),男,乌鲁木齐人,提高待遇高级工程师,研究方向为农业机械化技术装备,(E-mail)作者简介:王善博(1998-),男,山东威海人,硕士研究生,研究方向为农业机械化技术装备,(E-mail)wangshanbo@163.com

基金资助:

WANG Shanbo1( ), Alimu Maimaitituerxun1,2(

), Alimu Maimaitituerxun1,2( ), LI Qianxu2, DU Zhigao2, ZHANG Wei1

), LI Qianxu2, DU Zhigao2, ZHANG Wei1

Received:2023-05-18

Online:2024-01-20

Published:2024-02-21

Correspondence author:

Alimu Maimaitituerxun,(1973-),male,from Urumqi,Senior engineer,bachelor degree,research direction,(E-mail)Supported by:摘要:

【目的】设计一种鲜食玉米柔性采摘低损集穗收获割台,为鲜食玉米机械收获减损提供参考。【方法】设计一种两级过渡切削式拉茎辊,对摘穗过程进行运动学分析,拉茎辊与拨禾带尺寸及工作参数范围及切削式拉茎辊中心距取值范围91.65~107.00 mm,基于Hertz-Mindlin with bonding接触模型的离散元仿真分析拉茎辊中心距合适值在102 mm左右及拉茎辊采用交错刀式装配,以便有效减少因茎秆被扯断导致含杂率高。测试两种不同材质橡胶拨禾带耐疲劳性及橡胶拨禾带主要失效形式。【结果】设计了一种柔性采摘低损集穗收获割台,橡胶拨禾带主要失效形式为内圈传动齿磨损、拨禾带体断裂和外圈拨禾齿疲劳开胶,加氧化锌的丁腈橡胶拨禾带有更好抗磨损和抗疲劳性能。有效防止了因果穗磕碰搅龙叶片导致的籽粒损伤,在试验中籽粒破损率减小了0.08%。机器前进速度为7.2 km/h,拉茎辊中心距为103 mm,拉茎辊转速为700 r/min时作业效果最好。【结论】优化后试验平均籽粒破损率为0.368%,平均含杂率为0.43%,优于行业标准。

中图分类号:

王善博, 阿力木·买买提吐尔逊, 李谦绪, 杜志高, 张伟. 鲜食玉米柔性采摘低损集穗收获割台设计与试验[J]. 新疆农业科学, 2024, 61(1): 217-229.

WANG Shanbo, Alimu Maimaitituerxun, LI Qianxu, DU Zhigao, ZHANG Wei. Design of and experiment on fresh corn flexible picking and damage-free collectting harvest header[J]. Xinjiang Agricultural Sciences, 2024, 61(1): 217-229.

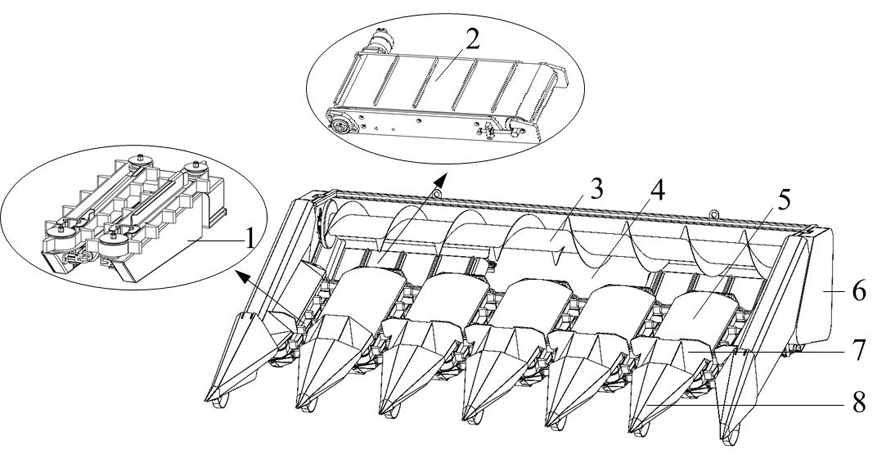

图1 鲜食玉米收获机割台结构示意 注:1.摘穗装置;2.集穗装置;3.输送搅龙;4.出料口;5.分禾罩;6.割台护壁;7.果穗护板;8.分禾器

Fig.1 Structure diagram of fresh corn harvester header Note:1.Fresh corn picking device;2.Collecting device;3. Stirrer conveyor;4.Outlet;5.Divided harvest cover;6.Harvest protectiving cover;7.Droping prevention of corn ears;8.Divider

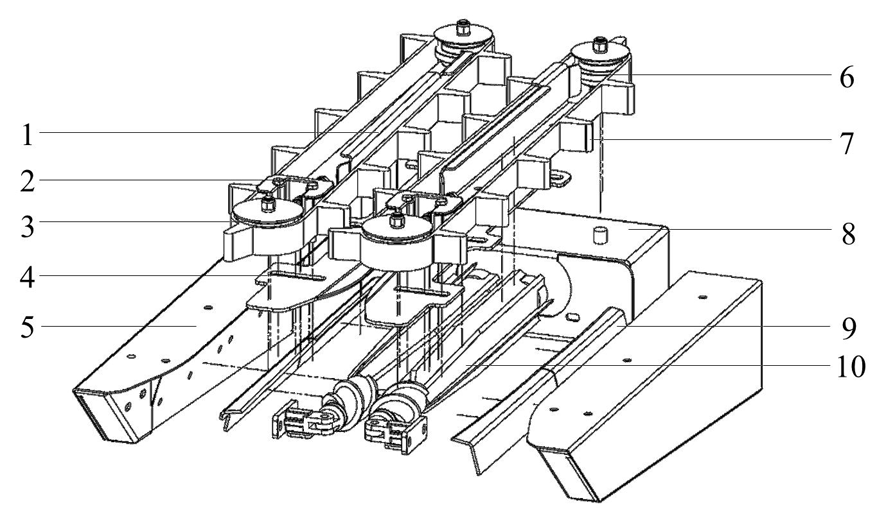

图2 鲜食玉米摘穗装置示意 1.皮带导板;2.张紧装置;3.拨禾带从动轮;4.摘穗板;5.摘穗架;6.拨禾带主动轮;7.橡胶拨禾带;8.齿轮箱;9.防堵塞定刀;10.切削式拉茎辊

Fig.2 Fresh corn picking device 1.Belt guiding;2.Tensioning device;3.Slave wheel;4.Spike picker board;5.Main body;6.Active wheel;7.Harvesting belt;8.Gearboxes;9. Fixed knife of Preventing blockade;10.Cutting-type stem pulling rollers

| 项目 Item | 参数 Parameter | 数值 Numerical value |

|---|---|---|

| 玉米茎秆 Corn stalks | 泊松比 | 0.4 |

| 密度(N·m3) | 1 060 | |

| 弹性模量(Pa) | 4.8×108 | |

| 结构钢 Structural steel | 泊松比 | 0.3 |

| 密度(N·m3) | 7 865 | |

| 弹性模量(Pa) | 7.5×1010 | |

| 玉米茎秆与玉米茎秆 Corn stalks and corn stalks | 恢复系数 | 0.485 |

| 静摩擦系数 | 0.142 | |

| 滚动摩擦系数 | 0.078 | |

| 玉米茎秆与结构钢 Corn stalks and structural steel | 恢复系数 | 0.663 |

| 静摩擦系数 | 0.226 | |

| 滚动摩擦系数 | 0.119 | |

| 粘结模型参数 Adhesive model parameters | 单位面积法向刚度 (N/m3) | 9.361×107 |

| 单位面积切向刚度 (N/m3) | 9.845×107 | |

| 临界法向应力(Mpa) | 8.72 | |

| 临界切向应力(Mpa) | 7.5 | |

| 粘结半径(mm) | 1.2 |

表1 仿真模型参数

Tab.1 Simulation model parameters

| 项目 Item | 参数 Parameter | 数值 Numerical value |

|---|---|---|

| 玉米茎秆 Corn stalks | 泊松比 | 0.4 |

| 密度(N·m3) | 1 060 | |

| 弹性模量(Pa) | 4.8×108 | |

| 结构钢 Structural steel | 泊松比 | 0.3 |

| 密度(N·m3) | 7 865 | |

| 弹性模量(Pa) | 7.5×1010 | |

| 玉米茎秆与玉米茎秆 Corn stalks and corn stalks | 恢复系数 | 0.485 |

| 静摩擦系数 | 0.142 | |

| 滚动摩擦系数 | 0.078 | |

| 玉米茎秆与结构钢 Corn stalks and structural steel | 恢复系数 | 0.663 |

| 静摩擦系数 | 0.226 | |

| 滚动摩擦系数 | 0.119 | |

| 粘结模型参数 Adhesive model parameters | 单位面积法向刚度 (N/m3) | 9.361×107 |

| 单位面积切向刚度 (N/m3) | 9.845×107 | |

| 临界法向应力(Mpa) | 8.72 | |

| 临界切向应力(Mpa) | 7.5 | |

| 粘结半径(mm) | 1.2 |

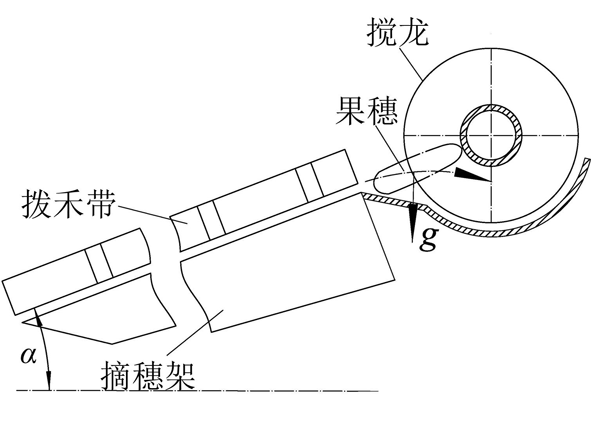

图12 以往玉米收获割台集穗过程 注:拨禾带的作用为向后拨动茎秆以及果穗。搅龙轴线方向为机器前进方向的垂直方向,搅龙对摘下的果穗进行横向的聚集、运输,摘下的果穗从各个摘穗装置被聚集的过程叫做集穗过程。

Fig.12 Maize cob collection diagram of previous harvesters Note:The function of the plucking belt is to move the stems and ears backwards,the axis direction of the agitator is the vertical direction of the machine's forward direction,the stirring dragon horizontally aggregates and transports the harvested fruit clusters,the process in which the harvested fruit ears are gathered from various picking devices is called the gathering process.

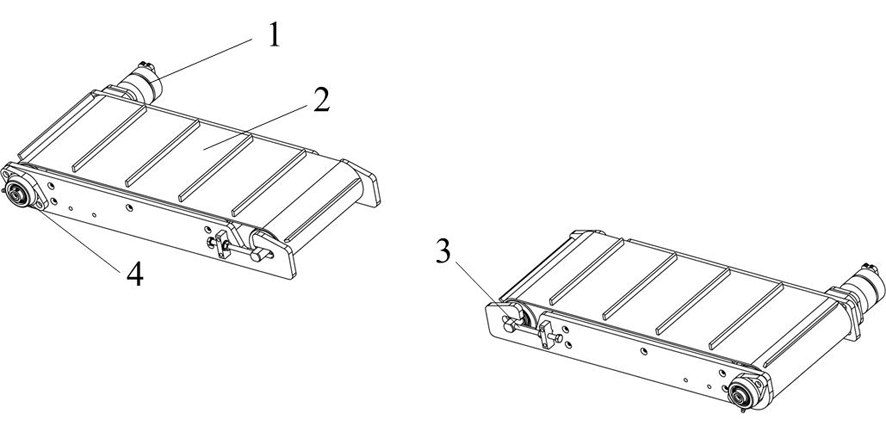

图14 低损集穗装置 注:1.液压马达;2.挡板输送带;3.张紧装置;4.主动辊轴承

Fig.14 Corn cob damage-free collection device Note:1.Hydraulic motor;2.Baffle conveyor;3.Tensioning device;4.Active roller bearing

| 水平 Level | 因素Factor | ||

|---|---|---|---|

| A(km/h) | B(mm) | C(rad/min) | |

| -1 | 7 | 99 | 700 |

| 0 | 8 | 102 | 800 |

| 1 | 9 | 105 | 900 |

表2 正交试验因素编码

Tab.2 Tset factors and codes

| 水平 Level | 因素Factor | ||

|---|---|---|---|

| A(km/h) | B(mm) | C(rad/min) | |

| -1 | 7 | 99 | 700 |

| 0 | 8 | 102 | 800 |

| 1 | 9 | 105 | 900 |

| 序号 Serial number | 试验因素 Test factors | Z (%) | H (%) | ||

|---|---|---|---|---|---|

| A | B | C | |||

| 1 | 0 | -1 | 1 | 0.64 | 2.56 |

| 2 | 0 | 0 | 0 | 0.38 | 0.81 |

| 3 | 0 | 0 | 0 | 0.42 | 0.79 |

| 4 | 0 | 0 | 0 | 0.45 | 0.81 |

| 5 | -1 | 0 | -1 | 0.33 | 0.39 |

| 6 | 0 | 0 | 0 | 0.42 | 0.77 |

| 7 | 0 | 1 | 1 | 0.65 | 0.91 |

| 8 | -1 | 1 | 0 | 0.55 | 0.42 |

| 9 | 0 | 0 | 0 | 0.44 | 0.83 |

| 10 | 1 | 1 | 0 | 0.74 | 0.56 |

| 11 | 1 | 0 | 1 | 0.81 | 1.62 |

| 12 | -1 | 0 | 1 | 0.57 | 0.75 |

| 13 | 1 | 0 | -1 | 0.52 | 0.81 |

| 14 | 0 | -1 | -1 | 0.41 | 1.52 |

| 15 | 1 | -1 | 0 | 0.64 | 1.98 |

| 16 | 0 | 1 | -1 | 0.45 | 0.36 |

| 17 | -1 | -1 | 0 | 0.48 | 1.72 |

表3 正交试验及结果

Tab.3 Test scheme and results

| 序号 Serial number | 试验因素 Test factors | Z (%) | H (%) | ||

|---|---|---|---|---|---|

| A | B | C | |||

| 1 | 0 | -1 | 1 | 0.64 | 2.56 |

| 2 | 0 | 0 | 0 | 0.38 | 0.81 |

| 3 | 0 | 0 | 0 | 0.42 | 0.79 |

| 4 | 0 | 0 | 0 | 0.45 | 0.81 |

| 5 | -1 | 0 | -1 | 0.33 | 0.39 |

| 6 | 0 | 0 | 0 | 0.42 | 0.77 |

| 7 | 0 | 1 | 1 | 0.65 | 0.91 |

| 8 | -1 | 1 | 0 | 0.55 | 0.42 |

| 9 | 0 | 0 | 0 | 0.44 | 0.83 |

| 10 | 1 | 1 | 0 | 0.74 | 0.56 |

| 11 | 1 | 0 | 1 | 0.81 | 1.62 |

| 12 | -1 | 0 | 1 | 0.57 | 0.75 |

| 13 | 1 | 0 | -1 | 0.52 | 0.81 |

| 14 | 0 | -1 | -1 | 0.41 | 1.52 |

| 15 | 1 | -1 | 0 | 0.64 | 1.98 |

| 16 | 0 | 1 | -1 | 0.45 | 0.36 |

| 17 | -1 | -1 | 0 | 0.48 | 1.72 |

| 序号 Serial number | 籽粒破损率 Grain damage rate(%) |

|---|---|

| 1 | 0.45 |

| 2 | 0.44 |

| 3 | 0.46 |

| 4 | 0.47 |

| 5 | 0.42 |

表4 试验结果

Tab.4 results test

| 序号 Serial number | 籽粒破损率 Grain damage rate(%) |

|---|---|

| 1 | 0.45 |

| 2 | 0.44 |

| 3 | 0.46 |

| 4 | 0.47 |

| 5 | 0.42 |

| 方差 来源 Variance source | Z | H | ||

|---|---|---|---|---|

| F | P | F | P | |

| 模型 Model | 32.39 | <0.000 1** | 34.15 | <0.000 1** |

| A | 79.1 | <0.000 1** | 162.49 | <0.000 1** |

| B | 6.29 | 0.040 5* | 20.42 | 0.002 7** |

| C | 119.82 | <0.000 1** | 97.8 | <0.000 1** |

| AB | 0.234 | 0.643 3 | 2.76 | 0.140 4 |

| AC | 0.650 1 | 0.446 6 | 7.73 | 0.027 3* |

| BC | 0.234 | 0.643 3 | 0.296 5 | 0.603 |

| A2 | 44.01 | 0.000 3** | 7.57 | 0.028 4* |

| B2 | 28.2 | 0.001 1** | 2.67 | 0.146 1 |

| C2 | 5.44 | 0.052 4 | 4.07 | 0.083 5 |

| 失拟项 Misfit term | 1.78 | 0.289 6 | 17.26 | 0.009 4* |

表5 籽粒破损率Z及含杂率H方差

Tab.5 Variance analysis for the damage rate of corn kernels and the rate of impurity

| 方差 来源 Variance source | Z | H | ||

|---|---|---|---|---|

| F | P | F | P | |

| 模型 Model | 32.39 | <0.000 1** | 34.15 | <0.000 1** |

| A | 79.1 | <0.000 1** | 162.49 | <0.000 1** |

| B | 6.29 | 0.040 5* | 20.42 | 0.002 7** |

| C | 119.82 | <0.000 1** | 97.8 | <0.000 1** |

| AB | 0.234 | 0.643 3 | 2.76 | 0.140 4 |

| AC | 0.650 1 | 0.446 6 | 7.73 | 0.027 3* |

| BC | 0.234 | 0.643 3 | 0.296 5 | 0.603 |

| A2 | 44.01 | 0.000 3** | 7.57 | 0.028 4* |

| B2 | 28.2 | 0.001 1** | 2.67 | 0.146 1 |

| C2 | 5.44 | 0.052 4 | 4.07 | 0.083 5 |

| 失拟项 Misfit term | 1.78 | 0.289 6 | 17.26 | 0.009 4* |

| 序号 Serial number | 籽粒破损率 Grain damage rate (%) | 含杂率 Trash content (%) |

|---|---|---|

| 1 | 0.36 | 0.44 |

| 2 | 0.38 | 0.40 |

| 3 | 0.36 | 0.43 |

| 4 | 0.35 | 0.51 |

| 5 | 0.39 | 0.37 |

表6 优化后试验结果

Tab.6 results of validation test

| 序号 Serial number | 籽粒破损率 Grain damage rate (%) | 含杂率 Trash content (%) |

|---|---|---|

| 1 | 0.36 | 0.44 |

| 2 | 0.38 | 0.40 |

| 3 | 0.36 | 0.43 |

| 4 | 0.35 | 0.51 |

| 5 | 0.39 | 0.37 |

| [1] | 中华人民共和国统计局. 中国统计年鉴[M]. 北京: 中国统计出版社, 2020. |

| National Bereau of Statostocs of China. China Statistical Yearbook[M]. Beijing: China Statistics Press, 2020. | |

| [2] | 张喜瑞, 吴鹏, 王克恒, 等. 4YZT-2型自走式鲜食玉米对行收获机设计与试验[J]. 农业工程学报, 2019, 35(13):1-9. |

| ZHANG Xirui, WU Peng, WANG Keheng, et al. Design and experiment of 4YZT-2 type self-propelled fresh corn double ridges harvester[J]. Transactions of the Chinese Society of Agricultural Engineering, 2019, 35(13):1-9. | |

| [3] | 陈志, 郝付平, 王锋德, 等. 中国玉米收获技术与装备发展研究[J]. 农业机械学报, 2012, 43(12):44-50. |

| ZHAO Zhi, HAO Fuping, WANG Fengde, et al. Development of Technology and Equipment of Corn Harvester in China[J]. Transactions of the Chinese Society for Agricultural Machinery, 2012, 43(12):44-50. | |

| [4] | 崔涛, 樊晨龙, 张东兴, 等. 玉米机械化收获技术研究进展分析[J]. 农业机械学报, 2019, 50(12):1-13. |

| CUI Tao, FAN Chenlong, ZHANG Dongxing, et al. Research Progress of Maize Mechanized Harvesting Technology[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(12):1-13. | |

| [5] | 徐丽, 赵久然, 卢柏山, 等. 我国鲜食玉米种业现状及发展趋势[J]. 中国种业, 2020,(10):14-18. |

| XU Li, ZHAO Jiuran, LU Boshan, et al. Current situation and development trend of fresh corn seed industry in China[J]. China Seed Industry, 2020,(10):14-18. | |

| [6] | 李坤, 黄长玲. 我国甜玉米产业发展现状、问题与对策[J]. 中国糖料, 2021, 43(1):67-71. |

| LI Kun, HUANG Changling. Current Production Status,Problem and Countermeasure on Sweet Corn In dustry in China[J]. Sugar Crops of China, 2021, 43(1):67-71. | |

| [7] |

任梦云, 杜龙岗, 王美兴, 等. 糯玉米可溶性糖组分特征与采后品质特征[J]. 浙江农业学报, 2022, 34(6):1133-1140.

DOI |

|

REN Mengyun, DU Longgang, WANG Meixing, et al. Characteristics of soluble sugar components in waxy corn and its postharvest quality[J]. Acta Agriculturae Zhejiangensis, 2022, 34(6):1133-1140.

DOI |

|

| [8] | Becerra S F, Taylor G. Reducing post-harvest losses and improving quality in sweet corn(Zea mays L.):challenges and solutions for less food waste and improved food security[J]. Food and Energy Security, 2021, 10(3):e277. |

| [9] | 王子明, 李春艳, 万世敏, 等. 广东省鲜食玉米产业发展经验与战略发展思路[J]. 作物杂志, 2014,(3):1-4. |

| WANG Ziming, LI Chuanyan, WAN Shimin, et al. Development experience and Strategic Development Idea of Fresh Corn Industry in Guangdong Province[J]. Crops, 2014,(3):1-4. | |

| [10] | 周福君, 官晓东, 唐遵峰, 等. 鲜食玉米果穗收获负压除杂装置参数优化与试验[J]. 农业机械学报, 2020, 51(11):138-147. |

| ZHOU Fujun, GUAN Xiaodong, TANG Zunfeng, et al. Parameter Optimization and Experiment of Negative Pressure ImpurityRemoval Device for Fresh Corn Ear Harvest[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(11):138-147. | |

| [11] | 刘传鑫. 鲜食玉米收获割台关键技术研究[D]. 长春: 吉林大学, 2019. |

| LIU Chuanxin. Research and Study on Key Technology of Fresh Corn Harvesting Header[D]. Changchun: Jilin University, 2019. | |

| [12] | 姚河江, 阿力木·买买提吐尔逊, 杜志高, 等. 牧神TY5650-11 鲜食玉米收获割台的研制[J]. 新疆农机化, 2018,(3):19-20. |

| YAO Hejiang, Alimu Maimaitituerxun, DU Zhigao, et al. Developing of Moshine TY5650-11 Fresh Corn Harvest Cutting Table[J]. Xinjiang Agricultural Mechanization, 2018,(3):19-20. | |

| [13] | 李天宇. 鲜食玉米柔性低损摘穗装置设计与试验[D]. 哈尔滨: 东北农业大学, 2019. |

| LI Tianyu. Design and Experiment on Flexible Low-loss Fresh Corn Picking Device[D]. Harbin:Northeast Agricultural University, 2019. | |

| [14] | 唐遵峰, 刘淑平, 周福君, 等. 制种玉米种穗收获机设计与试验[J]. 农业机械学报, 2021, 52(7):102-112. |

| TANG Zunfeng, LIU Shuping, ZHOU Fujun, et al. Design and Experiment of Ear Harvester for Seed Corn[J]. Transactions of the Chinese Society for Agricultural Machinery, 2021, 52(7):102-112. | |

| [15] | 尚书旗, 董佑福, 连正国, 等. 玉米联合收获机原理与应用[M]. 北京: 教育科学出版社, 2006. |

| Shang Shuqi, DONG Youfu, LIANG Zhenguo, et al. Principle and Application of Corn Combine Harvester[M]. Beijing: Educational Science Press, 2006. | |

| [16] |

刘海涛, 张炜, 马军民, 等. 青贮玉米饲料籽粒破碎装置仿真分析与试验[J]. 中国农机化学报, 2021, 42(8):32-39.

DOI |

| LIU Haitao, ZHANG Wei, MA Junmin, et al. Simulation analysis and experiment of silage corn feed grain crushing device[J]. Journal of Chinese Agricultural Mechanization, 2021, 42(8):32-39. | |

| [17] | 王丽. 外加氧化锌对丁腈橡胶隔膜耐磨性能的影响[D]. 沈阳: 沈阳大学, 2020. |

| WANG Li. Effect on Abrasion Resistance of Nitrile-Butadiene Rubber Diaphragm with Additional Zinc Oxide[D]. Shenyang: Shenyang University, 2020. | |

| [18] | Threepopnatkul P, Kulsetthanchalee C. Effect of ZnO and TiO2 on properties of polystyrene/nitrile rubber electrospun fiber mats[J]. Materials Today:Proceedings, 2018, 5(5):10917-10924. |

| [19] |

Sahoo S, Maiti M, Ganguly A, et al. Effect of zinc oxide nanoparticles as cure activator on the properties of natural rubber and nitrile rubber[J]. Journal of Applied Polymer Science, 2007, 105(4):2407-2415.

DOI URL |

| [20] | 中国农业机械化科学研究院. 农业机械设计手册:上册[M]. 北京: 中国农业科学技术出版社, 2007. |

| Chinese Academy of Agricultural Mechanization Sciences. Agricultural machinery design Manual:Volume 1[M]. Beijing: China Agricultural Science and Technology Press, 2007. | |

| [21] | 周祖锷. 农业物料学[M]. 北京: 中国农业出版社,1995. |

| ZHOU Zhue. Agricultural Materials[M].. Beijing: China Agriculture Press,1995. | |

| [22] | 张涛, 刘飞, 赵满全, 等. 玉米秸秆接触物理参数测定与离散元仿真标定[J]. 中国农业大学学报, 2018, 23(4):120-127. |

| ZHANG Tao, LIU Fei, ZHAO Manquan, et al. Determination of corn stalk contact parameters and calibration of Discrete Element Method simulation[J]. Journal of China Agricultural University, 2018, 23(4):120-127. | |

| [23] | GB/T21962-2020. 玉米收获机械[S]. |

| GB/T21962-2020. Corn Combine Harvesger[S]. |

| [1] | 尹鹏, 丁新华, 付开赟, 吐尔逊·阿合买提, 何江, 塔力木·再那力别克, 玛日耶姆·麦麦提, 台外库力·吾斯曼, 郭文超, 刘文. 播期对北疆鲜食玉米田节肢动物群落结构特征的影响[J]. 新疆农业科学, 2017, 54(9): 1659-1669. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||