Xinjiang Agricultural Sciences ›› 2025, Vol. 62 ›› Issue (5): 1273-1285.DOI: 10.6048/j.issn.1001-4330.2025.05.026

• Prataculture·Facility Agriculture • Previous Articles Next Articles

ZHANG Gaoshang1( ), WU Letian2,3, GUO Shenbo2,3, YUE Qiuxing2,3, SUN Xiaoli2,3, SHI Huifeng1,2(

), WU Letian2,3, GUO Shenbo2,3, YUE Qiuxing2,3, SUN Xiaoli2,3, SHI Huifeng1,2( )

)

Received:2024-10-07

Online:2025-05-20

Published:2025-07-09

Correspondence author:

SHI Huifeng

Supported by:

张高尚1( ), 吴乐天2,3, 郭申伯2,3, 岳秋星2,3, 孙小丽2,3, 史慧锋1,2(

), 吴乐天2,3, 郭申伯2,3, 岳秋星2,3, 孙小丽2,3, 史慧锋1,2( )

)

通讯作者:

史慧锋

作者简介:张高尚(1998-),男,硕士研究生,研究方向为设施农业智能装备工程,(E-mail)zgs666vip@163.com

基金资助:CLC Number:

ZHANG Gaoshang, WU Letian, GUO Shenbo, YUE Qiuxing, SUN Xiaoli, SHI Huifeng. Simulation and Optimization of a TRNSYS-Based Air-Source Heat Pump Integrated with Buried Pipe System for Solar Greenhouse Applications[J]. Xinjiang Agricultural Sciences, 2025, 62(5): 1273-1285.

张高尚, 吴乐天, 郭申伯, 岳秋星, 孙小丽, 史慧锋. 基于TRNSYS软件的日光温室空气源热泵-地埋管系统仿真与优化[J]. 新疆农业科学, 2025, 62(5): 1273-1285.

Add to citation manager EndNote|Ris|BibTeX

URL: https://www.xjnykx.com/EN/10.6048/j.issn.1001-4330.2025.05.026

| 设备 Equipment | 参数 Parameters | 数值 Value |

|---|---|---|

| 空气源热泵 Air source heat pump | 额定制热量(kW) | 30 |

| 额定输入功率(kW) | 10 | |

| 循环水泵 Circulating water pump | 流量(m3/h) | 8 |

| 额定功率(kW) | 1.5 | |

| 地埋管 Underground pipe | 水平间距(m) | 0.90 |

| 主管直径(mm) | 63 | |

| 支管直径(mm) | 32 | |

| 补水箱 Water supply tank | 水箱直径(m) | 0.40 |

| 水箱高度(m) | 1.00 |

Tab.1 Equipment Parameters

| 设备 Equipment | 参数 Parameters | 数值 Value |

|---|---|---|

| 空气源热泵 Air source heat pump | 额定制热量(kW) | 30 |

| 额定输入功率(kW) | 10 | |

| 循环水泵 Circulating water pump | 流量(m3/h) | 8 |

| 额定功率(kW) | 1.5 | |

| 地埋管 Underground pipe | 水平间距(m) | 0.90 |

| 主管直径(mm) | 63 | |

| 支管直径(mm) | 32 | |

| 补水箱 Water supply tank | 水箱直径(m) | 0.40 |

| 水箱高度(m) | 1.00 |

| 水平 Level | 因素Consideration | ||

|---|---|---|---|

热泵额定制热量 (kW) | (m3/h) | 日蓄热时长(h) | |

| -1 | 20 | 4 | 6 |

| 0 | 25 | 6 | 9 |

| 1 | 30 | 8 | 12 |

Tab.2 Factor and level design of ASHP-UP system response surface experiment design

| 水平 Level | 因素Consideration | ||

|---|---|---|---|

热泵额定制热量 (kW) | (m3/h) | 日蓄热时长(h) | |

| -1 | 20 | 4 | 6 |

| 0 | 25 | 6 | 9 |

| 1 | 30 | 8 | 12 |

| 试验 编号 Test number | 因素水平 Level of factors | 响应值 Response value | ||||

|---|---|---|---|---|---|---|

系统制 热量 (kWh) | (kWh) | 土壤 升温 (℃) | ||||

| 1 | 30 | 4 | 9 | 485.51 | 75.59 | 2.28 |

| 2 | 25 | 8 | 6 | 161.76 | 22.37 | 0.76 |

| 3 | 25 | 6 | 9 | 281.37 | 38.55 | 1.24 |

| 4 | 20 | 8 | 9 | 197.75 | 28.74 | 0.93 |

| 5 | 25 | 6 | 9 | 275.4 | 40.25 | 1.32 |

| 6 | 25 | 6 | 9 | 271.79 | 43.75 | 1.292 |

| 7 | 25 | 4 | 12 | 566.03 | 88.26 | 2.6 |

| 8 | 25 | 4 | 6 | 287.91 | 43.86 | 1.35 |

| 9 | 20 | 4 | 9 | 363.84 | 43.86 | 1.35 |

| 10 | 25 | 8 | 12 | 314.48 | 44.9 | 1.48 |

| 11 | 30 | 8 | 9 | 277.91 | 38.73 | 1.31 |

| 12 | 30 | 6 | 6 | 220.4 | 30.77 | 1.04 |

| 13 | 20 | 6 | 6 | 157.65 | 22.88 | 0.74 |

| 14 | 25 | 6 | 9 | 285.81 | 42.94 | 1.36 |

| 15 | 30 | 6 | 12 | 467.23 | 61.76 | 2.01 |

| 16 | 20 | 6 | 12 | 308.56 | 45.97 | 1.45 |

| 17 | 25 | 6 | 9 | 286.87 | 37.45 | 1.39 |

Tab.3 ASHP-UP system test program and results

| 试验 编号 Test number | 因素水平 Level of factors | 响应值 Response value | ||||

|---|---|---|---|---|---|---|

系统制 热量 (kWh) | (kWh) | 土壤 升温 (℃) | ||||

| 1 | 30 | 4 | 9 | 485.51 | 75.59 | 2.28 |

| 2 | 25 | 8 | 6 | 161.76 | 22.37 | 0.76 |

| 3 | 25 | 6 | 9 | 281.37 | 38.55 | 1.24 |

| 4 | 20 | 8 | 9 | 197.75 | 28.74 | 0.93 |

| 5 | 25 | 6 | 9 | 275.4 | 40.25 | 1.32 |

| 6 | 25 | 6 | 9 | 271.79 | 43.75 | 1.292 |

| 7 | 25 | 4 | 12 | 566.03 | 88.26 | 2.6 |

| 8 | 25 | 4 | 6 | 287.91 | 43.86 | 1.35 |

| 9 | 20 | 4 | 9 | 363.84 | 43.86 | 1.35 |

| 10 | 25 | 8 | 12 | 314.48 | 44.9 | 1.48 |

| 11 | 30 | 8 | 9 | 277.91 | 38.73 | 1.31 |

| 12 | 30 | 6 | 6 | 220.4 | 30.77 | 1.04 |

| 13 | 20 | 6 | 6 | 157.65 | 22.88 | 0.74 |

| 14 | 25 | 6 | 9 | 285.81 | 42.94 | 1.36 |

| 15 | 30 | 6 | 12 | 467.23 | 61.76 | 2.01 |

| 16 | 20 | 6 | 12 | 308.56 | 45.97 | 1.45 |

| 17 | 25 | 6 | 9 | 286.87 | 37.45 | 1.39 |

| 来源 Source | 平方和 Square sum | |||

|---|---|---|---|---|

| 模型 Model | 195 400.00 | 9 | 424.41 | < 0.000 1 |

| A | 22 392.57 | 1 | 437.82 | < 0.000 1 |

| B | 70 573.37 | 1 | 1 379.85 | < 0.000 1 |

| C | 85 818.10 | 1 | 1 677.92 | < 0.000 1 |

| AB | 430.77 | 1 | 8.42 | 0.022 9 |

| AC | 2 300.16 | 1 | 44.97 | 0.000 3 |

| BC | 3 931.29 | 1 | 76.86 | < 0.000 1 |

| B2 | 9 517.91 | 1 | 186.09 | < 0.000 1 |

Tab.4 System heat production regression ANOVA

| 来源 Source | 平方和 Square sum | |||

|---|---|---|---|---|

| 模型 Model | 195 400.00 | 9 | 424.41 | < 0.000 1 |

| A | 22 392.57 | 1 | 437.82 | < 0.000 1 |

| B | 70 573.37 | 1 | 1 379.85 | < 0.000 1 |

| C | 85 818.10 | 1 | 1 677.92 | < 0.000 1 |

| AB | 430.77 | 1 | 8.42 | 0.022 9 |

| AC | 2 300.16 | 1 | 44.97 | 0.000 3 |

| BC | 3 931.29 | 1 | 76.86 | < 0.000 1 |

| B2 | 9 517.91 | 1 | 186.09 | < 0.000 1 |

| 来源 Source | 平方和 Square sum | |||

|---|---|---|---|---|

| 模型Model | 4 602.38 | 9 | 32.06 | < 0.000 1 |

| A | 534.64 | 1 | 33.51 | 0.000 7 |

| B | 1 706.16 | 1 | 106.95 | < 0.000 1 |

| C | 1 830.43 | 1 | 114.74 | < 0.000 1 |

| AB | 118.16 | 1 | 7.41 | 0.029 7 |

| BC | 119.57 | 1 | 7.50 | 0.029 0 |

| B2 | 257.63 | 1 | 16.15 | 0.005 1 |

Tab.5 System energy consumption regression ANOVA

| 来源 Source | 平方和 Square sum | |||

|---|---|---|---|---|

| 模型Model | 4 602.38 | 9 | 32.06 | < 0.000 1 |

| A | 534.64 | 1 | 33.51 | 0.000 7 |

| B | 1 706.16 | 1 | 106.95 | < 0.000 1 |

| C | 1 830.43 | 1 | 114.74 | < 0.000 1 |

| AB | 118.16 | 1 | 7.41 | 0.029 7 |

| BC | 119.57 | 1 | 7.50 | 0.029 0 |

| B2 | 257.63 | 1 | 16.15 | 0.005 1 |

| 来源 Source | 平方和 Square sum | |||

|---|---|---|---|---|

| 模型Model | 3.79 | 9 | 47.27 | < 0.000 1 |

| A | 0.59 | 1 | 66.13 | < 0.000 1 |

| B | 1.20 | 1 | 134.95 | < 0.000 1 |

| C | 1.67 | 1 | 187.09 | < 0.000 1 |

| AB | 0.076 | 1 | 8.50 | 0.022 5 |

| BC | 0.070 | 1 | 7.89 | 0.026 2 |

| B2 | 0.16 | 1 | 17.49 | 0.004 1 |

Tab.6 Soil temperature rise regression ANOVA

| 来源 Source | 平方和 Square sum | |||

|---|---|---|---|---|

| 模型Model | 3.79 | 9 | 47.27 | < 0.000 1 |

| A | 0.59 | 1 | 66.13 | < 0.000 1 |

| B | 1.20 | 1 | 134.95 | < 0.000 1 |

| C | 1.67 | 1 | 187.09 | < 0.000 1 |

| AB | 0.076 | 1 | 8.50 | 0.022 5 |

| BC | 0.070 | 1 | 7.89 | 0.026 2 |

| B2 | 0.16 | 1 | 17.49 | 0.004 1 |

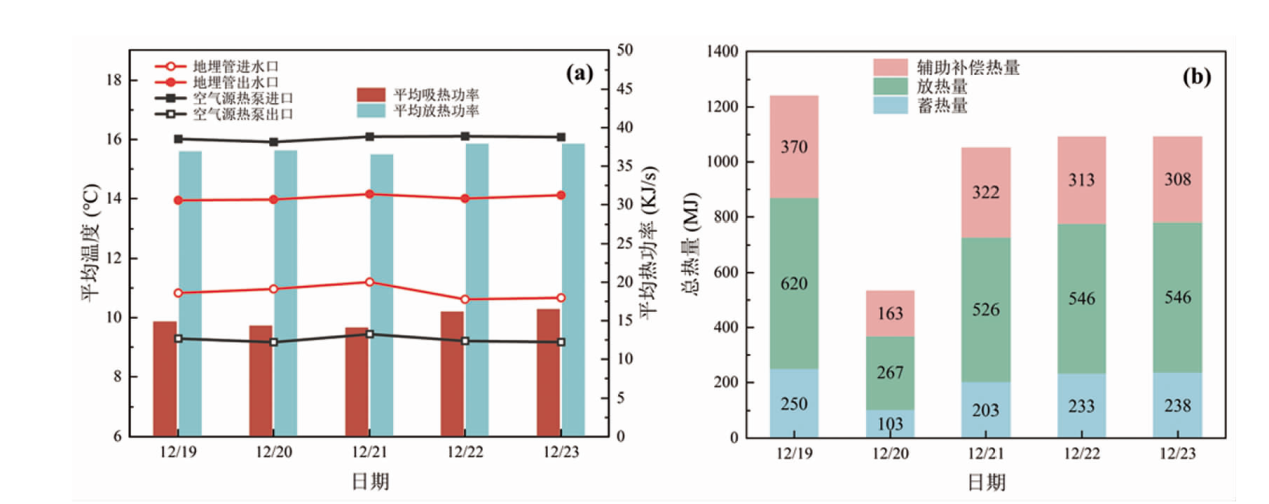

Fig.12 Thermal performance of system heating process Notes:(a) Average inlet and outlet temperature and heat transfer power; (b) Comparison of total heat absorbed and released

| 日期 Date (Y/M/D) | 天气 Climatic | 运行模式 Operating mode | 蓄放热量值 Heat storage and heat release values(MJ) | 蓄放热运行时间 Duration of heat storage and exothermic operation(h) | 蓄放热耗电量 Heat storage and exothermic power consumption (MJ) | 蓄热和放热COP Heat storage and exothermic COP |

|---|---|---|---|---|---|---|

| 2023/12/9 | 晴天 | 蓄热 | 596/- | 5.0/- | 140/- | 4.26/- |

| 2023/12/10 | 晴天 | 蓄热 | 556/- | 4.7/- | 132/- | 4.21/- |

| 2023/12/12 | 晴天 | 蓄热 | 534/- | 4.5/- | 126/- | 4.24/- |

| 2023/12/11 | 多云天 | 蓄热+放热 | 458/136 | 3.8/1.0 | 106/28 | 4.32/4.87 |

| 2023/12/14 | 多云天 | 蓄热+放热 | 394/278 | 3.2/2.0 | 90/56 | 4.38/4.96 |

| 2023/12/15 | 多云天 | 蓄热+放热 | 356/382 | 3.0/2.8 | 84/79 | 4.24/4.83 |

| 2023/12/8 | 阴天 | 蓄热 | 485/- | 4.0/- | 112/- | 4.32/- |

| 2023/12/13 | 阴天 | 蓄热+放热 | 424/214 | 3.5/1.6 | 98/45 | 4.33/4.75 |

| 2024/2/17 | 阴天 | 放热 | -/956 | -/7.2 | -/202 | -/4.74 |

| 2024/2/1 | 雪天 | 放热 | -/1138 | -/8.5 | -/238 | -/4.78 |

| 2024/2/18 | 雪天 | 放热 | -/990 | -/7.5 | -/210 | -/4.71 |

| 2024/2/19 | 雪天 | 放热 | -/1052 | -/7.8 | -/218 | -/4.82 |

Tab.7 Average values of heat pump COP and system COP under different conditions

| 日期 Date (Y/M/D) | 天气 Climatic | 运行模式 Operating mode | 蓄放热量值 Heat storage and heat release values(MJ) | 蓄放热运行时间 Duration of heat storage and exothermic operation(h) | 蓄放热耗电量 Heat storage and exothermic power consumption (MJ) | 蓄热和放热COP Heat storage and exothermic COP |

|---|---|---|---|---|---|---|

| 2023/12/9 | 晴天 | 蓄热 | 596/- | 5.0/- | 140/- | 4.26/- |

| 2023/12/10 | 晴天 | 蓄热 | 556/- | 4.7/- | 132/- | 4.21/- |

| 2023/12/12 | 晴天 | 蓄热 | 534/- | 4.5/- | 126/- | 4.24/- |

| 2023/12/11 | 多云天 | 蓄热+放热 | 458/136 | 3.8/1.0 | 106/28 | 4.32/4.87 |

| 2023/12/14 | 多云天 | 蓄热+放热 | 394/278 | 3.2/2.0 | 90/56 | 4.38/4.96 |

| 2023/12/15 | 多云天 | 蓄热+放热 | 356/382 | 3.0/2.8 | 84/79 | 4.24/4.83 |

| 2023/12/8 | 阴天 | 蓄热 | 485/- | 4.0/- | 112/- | 4.32/- |

| 2023/12/13 | 阴天 | 蓄热+放热 | 424/214 | 3.5/1.6 | 98/45 | 4.33/4.75 |

| 2024/2/17 | 阴天 | 放热 | -/956 | -/7.2 | -/202 | -/4.74 |

| 2024/2/1 | 雪天 | 放热 | -/1138 | -/8.5 | -/238 | -/4.78 |

| 2024/2/18 | 雪天 | 放热 | -/990 | -/7.5 | -/210 | -/4.71 |

| 2024/2/19 | 雪天 | 放热 | -/1052 | -/7.8 | -/218 | -/4.82 |

| 设备类型 Equipment type | 热效率 Thermal efficiency (%) | 标准煤 Standard coal (t) | 节能率 Energy saving ratio (%) | 碳量减排 Carbon reduction (t) |

|---|---|---|---|---|

| 空气源热泵 Air source heat pump | 4.56 | 0.60 | - | 1.50 |

| 燃煤锅炉 Coal-burning boiler | 0.70 | 3.91 | 84.7 | 9.74 |

| 燃气锅炉 Gas boiler | 0.85 | 3.22 | 81.4 | 8.02 |

| 电加热 Electrical heating | 0.95 | 2.88 | 79.2 | 7.17 |

Tab.8 Energy consumption and operating costs of different heating methods for greenhouses

| 设备类型 Equipment type | 热效率 Thermal efficiency (%) | 标准煤 Standard coal (t) | 节能率 Energy saving ratio (%) | 碳量减排 Carbon reduction (t) |

|---|---|---|---|---|

| 空气源热泵 Air source heat pump | 4.56 | 0.60 | - | 1.50 |

| 燃煤锅炉 Coal-burning boiler | 0.70 | 3.91 | 84.7 | 9.74 |

| 燃气锅炉 Gas boiler | 0.85 | 3.22 | 81.4 | 8.02 |

| 电加热 Electrical heating | 0.95 | 2.88 | 79.2 | 7.17 |

| [1] | Dong J, Gruda N, Li X, et al. Global vegetable supply towards sustainable food production and a healthy diet[J]. Clean Prod, 2022; 369. |

| [2] |

李天来, 齐明芳, 孟思达. 中国设施园艺发展60年成就与展望[J]. 园艺学报, 2022, 49(10)2119-2130.

DOI |

|

LI Tianlai, QI Mingfang, MENG Sida. Sixty Years of Facility Horticulture Development in China:Achievements and Prospects[J]. Acta Horticulturae Sinica, 2022, 49(10), 2119-2130.

DOI |

|

| [3] | 齐飞, 魏晓明, 张跃峰. 中国设施园艺装备技术发展现状与未来研究方向[J]. 农业工程学报, 2017, 33(24): 1-9. |

| QI Fei, WEI Xiaoming, ZHANG Yuefeng. Development status and future research emphase on greenhouse horticultural equipment and its relative technology in China[J]. Transactions of the CSAE, 2017, 33(24), 1-9. | |

| [4] | 鲍恩财, 曹晏飞, 邹志荣, 等. 节能日光温室蓄热技术研究进展[J]. 农业工程学报, 2018, 34(06): 1-14. |

| BAO Encai, CAO Yanfei, ZOU Zhirong, et al. Research progress of thermal storage technology in energy-saving solar greenhouse[J]. Transactions of the CSAE, 2018, 34(6), 1-14. | |

| [5] | 王洪义, 祖歌, 杨凤军, 等. 高纬度地区多功能日光温室设计[J]. 农业工程学报, 2020, 36(06): 170-178. |

| WANG Hongyi, ZU Ge, YANG Fengjun, et al. Design of multi-functional solar greenhouses in high latitude areas[J]. Transactions of the CSAE, 2020, 36(6), 170-178. | |

| [6] | 王瑞, 刘凯, 张书峰, 等. 沙漠组装式温室光热环境测试与分析[J]. 江苏农业科学, 2021, 49(18): 196-201. |

| WANG Rui, LIU Kai, ZHANG Shufeng, et al. Testing and analyzing the light and heat environment of desert-assembled greenhouses[J]. Jiangsu Agricultural Sciences, 2021, 49(18): 196-201. | |

| [7] | 孙维拓, 杨其长, 方慧, 等. 主动蓄放热-热泵联合加温系统在日光温室的应用[J]. 农业工程学报, 2013, 29(19): 168-177. |

| SUN Weituo, YANG Qichang, FANG Hui, et al. Application of heating system with active heat storage-release and heat pump in solar greenhouse[J]. Transactions of the CSAE, 2013, 29(19), 168-177. | |

| [8] | 孙维拓, 张义, 杨其长, 等. 温室主动蓄放热-热泵联合加温系统热力学分析[J]. 农业工程学报, 2014, 30(14): 179-188. |

| SUN Weituo, ZHANG Yi, YANG Qichang, et al. Thermodynamic analysis of active heat storage-release associated with heat pump heating system in greenhouse[J]. Transactions of the CSAE, 2014, 30(14), 179-188. | |

| [9] | Marsh L S, Singh S. Economics of greenhouse heating with a mine air-assisted heat pump[J]. Transactions of the ASAE, 1994, 37(6), 1959-1963. |

| [10] | Tong Y, Kozai T, Nishioka N, et al. Greenhouse heating using heat pumps with a high coefficient of performance (COP)[J]. Biosystems engineering, 2010, 106(4), 405-411. |

| [11] | Bot G, Van De Braak N, Challa H, et al. The solar greenhouse: state of the art in energy saving and sustainable energy supply[J]. Acta Horticulturae, 2005, 691(2), 501. |

| [12] | Amirirad A, Kumar R, Fung A S. Performance characterization of an indoor air source heat pump water heater for residential applications in Canada[J]. International Journal of Energy Research, 2018, 42(3), 1316-1327. |

| [13] | 李科宏. 空气源耦合地源一体化热泵系统性能研究[D]. 太原: 太原理工大学, 2020. |

| LI Kehong. Performance of Air Source Coupling Ground Source Integrated Heat Pump System[D]. Taiyuan: Taiyuan University of Technology, 2020. | |

| [14] | 贾宋楠, 范凤翠, 刘胜尧, 等. 地温加热对日光温室蔬菜根层土壤的升温效应[J]. 江苏农业科学, 2021, 49(21): 205-211. |

| JIA Songnan, FAN Fengcui, LIU Shengyao, et al. Warming effect of geothermal heating on the rhizosphere soil of solar greenhouse vegetables[J]. Jiangsu Agricultural Sciences, 2021, 49(21): 205-211. | |

| [15] | 郭智勇, 王冬计, 王晓雪, 等. 地埋管供热对蔬菜大棚土壤温湿度分布影响的模拟研究[J]. 沈阳农业大学学报, 2022, 53(1): 73-82. |

| GUO Zhiyong, WANG Dongji, WANG Xiaoxue, et al. Simulation Study on Effect of Buried Pipe Heating on Distribution of Soil Temperature and Moisture in Vegetable Greenhouse[J]. Journal of Shenyang Agricultural University, 2022, 53(1): 73-82. | |

| [16] | 甄琦, 杜嘉玮, 塔娜, 等. 温室传热水道与土壤换热强度影响的数值分析[J]. 农机化研究, 2024, 46(9): 257-263. |

| ZHEN Qi, DU Jiawei, TA Na, et al. Numerical Analysis of the Influence of Solar Greenhouse Heating Channels and Soil Heat Transfer Intensity in Cold and Arid Areas[J]. Journal of Agricultural Mechanization Research, 2024, 46(9), 257-263. | |

| [17] | 鲍玲玲, 耿杰雯, 朱淑静, 等. 温室用地埋管与空气源热泵系统运行特性研究[J]. 农机化研究, 2020, 42(12): 258-264. |

| BAO Lingling, GENG Jiewen, ZHU Shujing, et al. Study on Operation Characteristics of Ground Pipe and Air Source Heat Pump System in Greenhouse[J]. Journal of Agricultural Mechanization Research, 2020, 42(12), 258-264. | |

| [18] | 鲍玲玲, 崔军艳, 李永, 等. 空气源热泵-地埋管换热系统蓄热性能研究[J]. 科学技术与工程, 2022, 22(24): 10688-10697. |

| BAO Lingling, CUI Junyan, LI Yong, et al. Heat Storage Performance of Air Source Heat Pump Underground Buried Pipe Heat Exchange System.[J]. Journal of Agricultural Mechanization Research, 2022, 22(24): 10688-10697. | |

| [19] | 李永, 崔军艳, 李冬, 等. 空气-土壤蓄热式热泵系统的实测与模拟研究[J]. 制冷与空调, 2024, 24(5): 52-59. |

| LI Yong, CUI Junyan, LI Dong, et al. Measurement and simulation of air-soil regenerative heat pump system[J]. Refrigeration and air-conditioning, 2024, 24(5): 52-59. | |

| MA Qianwei, LI Ming, SONG Weitang, et al. Heat storage and release characteristics of the combined heat storage system for prefabricated solar greenhouses with flexible material wall[J]. Transactions of the CSAE, 2024, 40(15): 183-193. | |

| [20] | 田东坤, 宋卫堂, 王平智, 等. 严寒地区保温型塑料大棚土壤蓄放热特性[J]. 农业工程学报, 2022, 38(03): 189-196. |

| TIAN Dongkun, SONG Weitang, WANG Pingzhi, et al. Soil heat storage and release characteristics of the plastic tunnel with external thermal insulation[J]. Transactions of the CSAE, 2022, 38(3): 189-196. | |

| [21] | 马承伟. 塑料大棚地下热交换系统的研究[J]. 农业工程学报, 1985, (01): 54-65. |

| Ma Chengwei. Studies on the vinyl-house house heating by the underground heat exchange system[J]. Transactions of the CSAE, 1985, (1): 54-65. | |

| [22] | 孙先鹏, 郭康权, 邹志荣, 等. 太阳能联合空气源热泵系统温室供热实验研究[J]. 太阳能学报, 2016, 37(3): 658-665. |

| SUN Xianpeng, GUO Kangquan, ZOU Zhirong, et al. System investigation of a solar combined with air-source heat pump system for greenhouse heating[J]. Acta Energiae Solaris Sinica, 2016, 37(3): 658-665. | |

| [23] | 周升, 张义, 程瑞锋, 等. 大跨度主动蓄能型温室温湿环境监测及节能保温性能评价[J]. 农业工程学报, 2016, 32(6): 218-225. |

| ZHOU Sheng, ZHANG Yi, CHENG Ruifeng, et al. Evaluation on heat preservation effects in micro environment of large-scale greenhouse with active heat storage system[J]. Transactions of the CSAE, 2016, 32(6): 218-225. | |

| [24] | 孙雪丽, 李辉, 王圣, 等. 基于烟气治理全过程的煤电行业SO3减排潜力研究[J/OL]. 中国电机工程学报, 1-11[2024-10-19]. |

| SUN Xueli, LI Hui, WANG Sheng, et al. Study on the Potential of SO3 Emission Reduction from Coal Power Industry in China Through the Analysis of Whole Smoke treatment Process[J]. Proceedings of the CSEE. 2024, 1-11. | |

| [25] | 张勇, 倪欣宇, 张柯新, 等. 光伏驱动基质控温系统对温室番茄根区的降温效果[J]. 农业工程学报, 2020, 36(5): 212-219. |

| ZHANG Yong, NI Xinyu, ZHANG Kexin, et al. Cooling performance for tomato root zone with intelligent ecological planting matrix temperature control system driven by photovoltaic in greenhouse[J]. Transactions of the CSAE, 2020, 36(5): 212-219. | |

| [26] | 冯硕, 胡文举, 李德英. 农业建筑中供暖方式及设备的选择[J]. 天津农业科学, 2017, 23(9): 78-81. |

| FENG Shuo, HU Wenju, LI Deying. Heating Mode and Equipment Selection during Agricultural Construction[J]. Tianjin Agricultural Sciences, 2017, 23(9):78-81. | |

| [27] | 姚益平, 戴剑锋, 罗卫红, 等. 中国连栋温室黄瓜周年生产能耗分布模拟[J]. 农业工程学报, 2011, 27(1): 273-279. |

| YAO Yiping, DAI Jianfeng, LUO Weihong, et al. Simulation analysis of distribution of energy consumption for year round cucumber production in multi-span greenhouse in China[J]. Transactions of the CSAE, 2011, 27(1), 273-279. | |

| [28] |

李金平, 董玉慧, 李彩军, 等. 寒冷地区空气源热泵辅助太阳能热水器供暖性能[J]. 上海交通大学学报, 2023, 57(7): 910-920.

DOI |

|

LI Jinping, DONG Yuhui, LI Caijun et al. Performance of Solar Vacuum Tube Water Heater-Air Source Heat Pump System in Cold Area[J]. Journal of Shanghai Jiaotong University, 2023, 57(7): 910-920.

DOI |

|

| [29] |

李金平, 李彩军, 李天澍, 等. 寒冷地区户用大平板太阳能集热器-空气源热泵系统性能研究[J]. 太阳能学报, 2023, 44(5): 246-256.

DOI |

|

LI Jinping, LI Caijun, LI Tianshu, et al. Study on Performance of Household Large flat plate Solar Collector-Air Source Heat Pump System in Cold Area[J]. Acta Energiae Solaris Sinica, 2023, 44(5): 246-256.

DOI |

|

| [30] | 徐微微, 马承伟, 宋卫堂, 等. 日光温室中空板水循环集放热系统设计与集热性能试验[J]. 农业机械学报, 2018, 49(7): 326-334. |

| XU Weiwei, MA Chengwei, SONG Weitang, et al. Test on Heat-collecting Performance of Solar Heat Collection and Release System with Water Cycling inside Hollow Plates in Chinese Solar Greenhouse[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(7): 326-334. | |

| [31] | 李明, 李涵, 宋卫堂, 等. 基于毛细管网的日光温室主动式集放热系统研究[J]. 农业机械学报, 2019, 50(11): 341-349. |

| LI Ming, LI Han, SONG Weitang, et al. Application of Active Heat System Developed with Capillary Tube Mates in Chinese Solar Greenhouse[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(11): 341-349. | |

| [32] | 马蔷薇, 李明, 宋卫堂, 等. 装配式柔性墙体日光温室联合储热系统蓄放热特性[J]. 农业工程学报, 2024, 40(15): 183-193. |

| [33] | 陈红超. 空气源热泵机组在室内应用设计简介[J]. 城市建筑, 2016, 0(17): 34-34. |

| CHEN Hongchao. Air Source Heat Pump Units in Indoor Applications Design Introduction[J]. Urbanism And Architecture, 2016, 0(17): 34-34. |

| [1] | RAN Qi-ying;ZHOU Hui. Regional Differences and Convergence Analysis of Agricultural Total Factor Energy Efficiency in China: 1997-2012 [J]. , 2015, 52(6): 1169-1176. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||