Xinjiang Agricultural Sciences ›› 2022, Vol. 59 ›› Issue (8): 2014-2024.DOI: 10.6048/j.issn.1001-4330.2022.08.023

• Plant Protection·Agricultural Product Analysis and Detection·Agricultural Equipment Engineering and Mechanization • Previous Articles Next Articles

LI Qingchao1( ), ZHENG Xuan2(

), ZHENG Xuan2( ), LIU Jinbao2, YANG Huaijun2, WANG Zilong2, ZHANG Luyun2

), LIU Jinbao2, YANG Huaijun2, WANG Zilong2, ZHANG Luyun2

Received:2022-03-24

Online:2022-08-20

Published:2022-10-01

Correspondence author:

ZHENG Xuan

Supported by:

李清超1( ), 郑炫2(

), 郑炫2( ), 刘进宝2, 杨怀君2, 王子龙2, 张鲁云2

), 刘进宝2, 杨怀君2, 王子龙2, 张鲁云2

通讯作者:

郑炫

作者简介:李清超(1996-),男,硕士研究生,研究方向为农业机械,(E-mail) 1123262436@qq.com

基金资助:CLC Number:

LI Qingchao, ZHENG Xuan, LIU Jinbao, YANG Huaijun, WANG Zilong, ZHANG Luyun. Parameter Calibration of Discrete Element Simulation of Farmland Silt in Xinjiang[J]. Xinjiang Agricultural Sciences, 2022, 59(8): 2014-2024.

李清超, 郑炫, 刘进宝, 杨怀君, 王子龙, 张鲁云. 新疆农田粉土离散元仿真参数标定[J]. 新疆农业科学, 2022, 59(8): 2014-2024.

Add to citation manager EndNote|Ris|BibTeX

URL: https://www.xjnykx.com/EN/10.6048/j.issn.1001-4330.2022.08.023

| 密度 Density (kg/m3) | 含水率 Moisture content (%) | 泊松比 Poisson's ratio | 粒径分布占比 Size ratio (%) | ||

|---|---|---|---|---|---|

| 1 480 | 14.5 | 0.37 | <0.001mm | 0.001~0.05mm | >0.05mm |

| 1.82 | 85.55 | 12.63 | |||

Table 1 Soil constitutive parameters

| 密度 Density (kg/m3) | 含水率 Moisture content (%) | 泊松比 Poisson's ratio | 粒径分布占比 Size ratio (%) | ||

|---|---|---|---|---|---|

| 1 480 | 14.5 | 0.37 | <0.001mm | 0.001~0.05mm | >0.05mm |

| 1.82 | 85.55 | 12.63 | |||

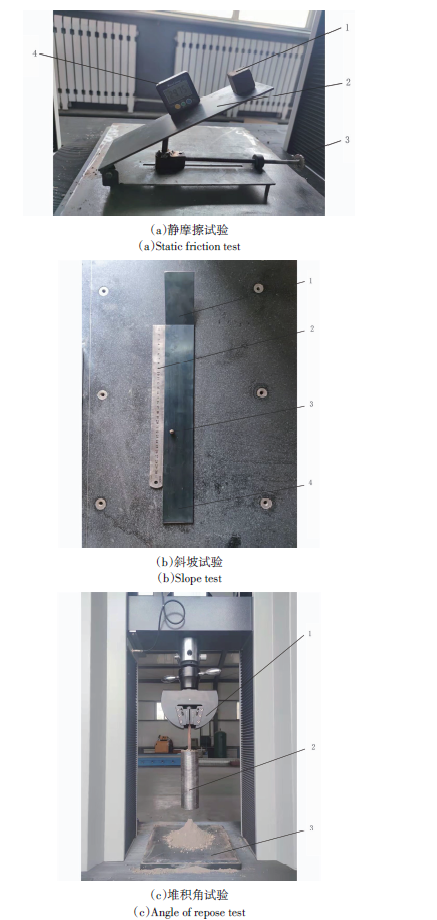

Fig. 1 Actual physical test Note:(a)1.Soil block,2.Inclined plane,3.Rotating rod,4.Cant instrument;(b)1.65-Mn slope,2.Steel rulers,3.Soil particle,4.65-Mn plane;(c)1.Universal testing machine,2.Cylinder,3.Plane

| 材料 Material | 参数 Parameter | 数值 The values | 来源 Source |

|---|---|---|---|

| 土壤 Soil | 泊松比 | 0.37 | 测量 |

| 密度 | 1 480 kg/m3 | 测量 | |

| 剪切模量 | 1 MPa | 参考 | |

| 65Mn | 泊松比 | 0.29 | 参考 |

| 密度 | 7 861 kg/m3 | 参考 | |

| 剪切模量 | 7.9×10 000 MPa | 参考 |

Table 2 Constitutive parameters of soil and 65Mn

| 材料 Material | 参数 Parameter | 数值 The values | 来源 Source |

|---|---|---|---|

| 土壤 Soil | 泊松比 | 0.37 | 测量 |

| 密度 | 1 480 kg/m3 | 测量 | |

| 剪切模量 | 1 MPa | 参考 | |

| 65Mn | 泊松比 | 0.29 | 参考 |

| 密度 | 7 861 kg/m3 | 参考 | |

| 剪切模量 | 7.9×10 000 MPa | 参考 |

| 编码 Code | 恢复系数A Recoverycoefficient A | 静摩擦系数B Static friction coefficient B | 动摩擦系数C Dynamic friction coefficient C | JKR表面能D JKR surface energy D(J/m2) |

|---|---|---|---|---|

| 1.718 | 0.6 | 0.8 | 0.2 | 7 |

| 1 | 0.558 | 0.675 | 0.167 | 5.746 |

| 0 | 0.5 | 0.5 | 0.12 | 4 |

| -1 | 0.442 | 0.325 | 0.073 | 2.254 |

| -1.718 | 0.4 | 0.2 | 0.04 | 1 |

Table 3 Factor level coding table of soil-65Mn simulation test

| 编码 Code | 恢复系数A Recoverycoefficient A | 静摩擦系数B Static friction coefficient B | 动摩擦系数C Dynamic friction coefficient C | JKR表面能D JKR surface energy D(J/m2) |

|---|---|---|---|---|

| 1.718 | 0.6 | 0.8 | 0.2 | 7 |

| 1 | 0.558 | 0.675 | 0.167 | 5.746 |

| 0 | 0.5 | 0.5 | 0.12 | 4 |

| -1 | 0.442 | 0.325 | 0.073 | 2.254 |

| -1.718 | 0.4 | 0.2 | 0.04 | 1 |

| 编码 Code | 恢复系数X1 Recovery coefficient X1 | 静摩擦系数X2 Static friction coefficient X2 | 动摩擦系数X3 Dynamic friction coefficient X3 | JKR表面能X4 JKR surface energy X4(J/m2) |

|---|---|---|---|---|

| 1.718 | 0.8 | 1 | 0.45 | 8 |

| 1 | 0.716 | 0.833 | 0.366 | 6.537 |

| 0 | 0.6 | 0.6 | 0.25 | 4.5 |

| -1 | 0.484 | 0.367 | 0.134 | 2.463 |

| -1.718 | 0.4 | 0.2 | 0.05 | 1 |

Table 4 Factor level coding table of soil-soil simulation test

| 编码 Code | 恢复系数X1 Recovery coefficient X1 | 静摩擦系数X2 Static friction coefficient X2 | 动摩擦系数X3 Dynamic friction coefficient X3 | JKR表面能X4 JKR surface energy X4(J/m2) |

|---|---|---|---|---|

| 1.718 | 0.8 | 1 | 0.45 | 8 |

| 1 | 0.716 | 0.833 | 0.366 | 6.537 |

| 0 | 0.6 | 0.6 | 0.25 | 4.5 |

| -1 | 0.484 | 0.367 | 0.134 | 2.463 |

| -1.718 | 0.4 | 0.2 | 0.05 | 1 |

| 试验号 Number | 恢复系数A Recoverycoefficient A | 静摩擦 系数B Static friction coefficient B | 动摩擦系数C Dynamic friction coefficient C | JKR表面能D JKR surface energy D (J/m2) | 滚动 距离 (mm) |

|---|---|---|---|---|---|

| 1 | -1 | -1 | -1 | -1 | 250.48 |

| 2 | 1 | -1 | -1 | -1 | 247.36 |

| 3 | -1 | 1 | -1 | -1 | 245.52 |

| 4 | 1 | 1 | -1 | -1 | 251.77 |

| 5 | -1 | -1 | 1 | -1 | 57.05 |

| 6 | 1 | -1 | 1 | -1 | 52.21 |

| 7 | -1 | 1 | 1 | -1 | 54.65 |

| 8 | 1 | 1 | 1 | -1 | 52.39 |

| 9 | -1 | -1 | -1 | 1 | 192.34 |

| 10 | 1 | -1 | -1 | 1 | 213.16 |

| 11 | -1 | 1 | -1 | 1 | 203.35 |

| 12 | 1 | 1 | -1 | 1 | 217.54 |

| 13 | -1 | -1 | 1 | 1 | 27.76 |

| 14 | 1 | -1 | 1 | 1 | 41.09 |

| 15 | -1 | 1 | 1 | 1 | 39.51 |

| 16 | 1 | 1 | 1 | 1 | 41.58 |

| 17 | -1.719 | 0 | 0 | 0 | 105.32 |

| 18 | 1.719 | 0 | 0 | 0 | 100.15 |

| 19 | 0 | -1.719 | 0 | 0 | 99.64 |

| 20 | 0 | 1.719 | 0 | 0 | 98.71 |

| 21 | 0 | 0 | -1.719 | 0 | 328.36 |

| 22 | 0 | 0 | 1.719 | 0 | 27.67 |

| 23 | 0 | 0 | 0 | -1.719 | 122.65 |

| 24 | 0 | 0 | 0 | 1.719 | 78.32 |

| 25 | 0 | 0 | 0 | 0 | 156.4 |

| 26 | 0 | 0 | 0 | 0 | 142.99 |

| 27 | 0 | 0 | 0 | 0 | 163.86 |

| 28 | 0 | 0 | 0 | 0 | 138.19 |

| 29 | 0 | 0 | 0 | 0 | 152.97 |

| 30 | 0 | 0 | 0 | 0 | 159.41 |

Table 5 Slope simulation test design and results

| 试验号 Number | 恢复系数A Recoverycoefficient A | 静摩擦 系数B Static friction coefficient B | 动摩擦系数C Dynamic friction coefficient C | JKR表面能D JKR surface energy D (J/m2) | 滚动 距离 (mm) |

|---|---|---|---|---|---|

| 1 | -1 | -1 | -1 | -1 | 250.48 |

| 2 | 1 | -1 | -1 | -1 | 247.36 |

| 3 | -1 | 1 | -1 | -1 | 245.52 |

| 4 | 1 | 1 | -1 | -1 | 251.77 |

| 5 | -1 | -1 | 1 | -1 | 57.05 |

| 6 | 1 | -1 | 1 | -1 | 52.21 |

| 7 | -1 | 1 | 1 | -1 | 54.65 |

| 8 | 1 | 1 | 1 | -1 | 52.39 |

| 9 | -1 | -1 | -1 | 1 | 192.34 |

| 10 | 1 | -1 | -1 | 1 | 213.16 |

| 11 | -1 | 1 | -1 | 1 | 203.35 |

| 12 | 1 | 1 | -1 | 1 | 217.54 |

| 13 | -1 | -1 | 1 | 1 | 27.76 |

| 14 | 1 | -1 | 1 | 1 | 41.09 |

| 15 | -1 | 1 | 1 | 1 | 39.51 |

| 16 | 1 | 1 | 1 | 1 | 41.58 |

| 17 | -1.719 | 0 | 0 | 0 | 105.32 |

| 18 | 1.719 | 0 | 0 | 0 | 100.15 |

| 19 | 0 | -1.719 | 0 | 0 | 99.64 |

| 20 | 0 | 1.719 | 0 | 0 | 98.71 |

| 21 | 0 | 0 | -1.719 | 0 | 328.36 |

| 22 | 0 | 0 | 1.719 | 0 | 27.67 |

| 23 | 0 | 0 | 0 | -1.719 | 122.65 |

| 24 | 0 | 0 | 0 | 1.719 | 78.32 |

| 25 | 0 | 0 | 0 | 0 | 156.4 |

| 26 | 0 | 0 | 0 | 0 | 142.99 |

| 27 | 0 | 0 | 0 | 0 | 163.86 |

| 28 | 0 | 0 | 0 | 0 | 138.19 |

| 29 | 0 | 0 | 0 | 0 | 152.97 |

| 30 | 0 | 0 | 0 | 0 | 159.41 |

| 方差来源 Variance source | 平方和 Sum of squares | 自由度 Freedom | 均方 mean square | F值 F value | P值 P Value | |

|---|---|---|---|---|---|---|

| 模型 Model | 1.930E+005 | 14 | 13 789.05 | 63.93 | <0.000 1 | ** |

| A | 64.37 | 1 | 64.37 | 0.3 | 0.592 9 | |

| B | 24.7 | 1 | 24.7 | 0.11 | 0.739 8 | |

| C | 1.775E+005 | 1 | 1.775E+005 | 823.04 | <0.000 1 | ** |

| D | 4423.12 | 1 | 4 423.12 | 20.51 | 0.000 4 | ** |

| AB | 2.21 | 1 | 2.21 | 0.01 | 0.920 8 | |

| AC | 55.65 | 1 | 55.65 | 0.26 | 0.618 9 | |

| AD | 184.82 | 1 | 184.82 | 0.86 | 0.369 3 | |

| BC | 1.45 | 1 | 1.45 | 6.732E-003 | 0.935 7 | |

| BD | 57.76 | 1 | 57.76 | 0.27 | 0.612 4 | |

| CD | 655.10 | 1 | 655.10 | 3.04 | 0.101 8 | |

| A2 | 1 693.57 | 1 | 1 693.57 | 7.85 | 0.013 4 | * |

| B2 | 2 133.29 | 1 | 2 133.29 | 9.89 | 0.006 7 | * |

| C2 | 4 265.27 | 1 | 4 265.27 | 19.78 | 0.000 5 | ** |

| D2 | 1 965.59 | 1 | 1 965.59 | 9.11 | 0.008 6 | * |

| 残差 | 3 235.34 | 15 | 215.69 | |||

| 失拟项 | 2 748.12 | 10 | 274.81 | 2.82 | 0.1320 | |

| 误差 | 487.21 | 5 | 97.44 | |||

| 总和 | 1.963E+005 | 29 |

Table 6 Variance analysis of slope simulation test

| 方差来源 Variance source | 平方和 Sum of squares | 自由度 Freedom | 均方 mean square | F值 F value | P值 P Value | |

|---|---|---|---|---|---|---|

| 模型 Model | 1.930E+005 | 14 | 13 789.05 | 63.93 | <0.000 1 | ** |

| A | 64.37 | 1 | 64.37 | 0.3 | 0.592 9 | |

| B | 24.7 | 1 | 24.7 | 0.11 | 0.739 8 | |

| C | 1.775E+005 | 1 | 1.775E+005 | 823.04 | <0.000 1 | ** |

| D | 4423.12 | 1 | 4 423.12 | 20.51 | 0.000 4 | ** |

| AB | 2.21 | 1 | 2.21 | 0.01 | 0.920 8 | |

| AC | 55.65 | 1 | 55.65 | 0.26 | 0.618 9 | |

| AD | 184.82 | 1 | 184.82 | 0.86 | 0.369 3 | |

| BC | 1.45 | 1 | 1.45 | 6.732E-003 | 0.935 7 | |

| BD | 57.76 | 1 | 57.76 | 0.27 | 0.612 4 | |

| CD | 655.10 | 1 | 655.10 | 3.04 | 0.101 8 | |

| A2 | 1 693.57 | 1 | 1 693.57 | 7.85 | 0.013 4 | * |

| B2 | 2 133.29 | 1 | 2 133.29 | 9.89 | 0.006 7 | * |

| C2 | 4 265.27 | 1 | 4 265.27 | 19.78 | 0.000 5 | ** |

| D2 | 1 965.59 | 1 | 1 965.59 | 9.11 | 0.008 6 | * |

| 残差 | 3 235.34 | 15 | 215.69 | |||

| 失拟项 | 2 748.12 | 10 | 274.81 | 2.82 | 0.1320 | |

| 误差 | 487.21 | 5 | 97.44 | |||

| 总和 | 1.963E+005 | 29 |

| 参数Parameter | 数值The values |

|---|---|

| 土壤-65Mn恢复系数 | 0.51 |

| Soil-65Mn Recovery coefficient | |

| 土壤-65Mn静摩擦系数 | 0.56 |

| Soil-65MnStatic friction coefficient | |

| 土壤-65Mn滚动摩擦系数 | 0.08 |

| Soil-65MnDynamic friction coefficient | |

| 土壤-65Mn JKR表面能 | 4.12 |

| Soil-65MnJKR surface energy |

Table 7 Parameters of soil-65mn contact model

| 参数Parameter | 数值The values |

|---|---|

| 土壤-65Mn恢复系数 | 0.51 |

| Soil-65Mn Recovery coefficient | |

| 土壤-65Mn静摩擦系数 | 0.56 |

| Soil-65MnStatic friction coefficient | |

| 土壤-65Mn滚动摩擦系数 | 0.08 |

| Soil-65MnDynamic friction coefficient | |

| 土壤-65Mn JKR表面能 | 4.12 |

| Soil-65MnJKR surface energy |

| 试验号 Number | 恢复 系数X1 | 静摩擦 系数X2 | 动摩擦 系数X3 | 表面能X4(J/m2) | 堆积角(°) |

|---|---|---|---|---|---|

| 1 | -1 | -1 | -1 | -1 | 33.82 |

| 2 | 1 | -1 | -1 | -1 | 44.08 |

| 3 | -1 | 1 | -1 | -1 | 38.18 |

| 4 | 1 | 1 | -1 | -1 | 32.92 |

| 5 | -1 | -1 | 1 | -1 | 33.4 |

| 6 | 1 | -1 | 1 | -1 | 31.02 |

| 7 | -1 | 1 | 1 | -1 | 31.35 |

| 8 | 1 | 1 | 1 | -1 | 52.39 |

| 9 | -1 | -1 | -1 | 1 | 45.2 |

| 10 | 1 | -1 | -1 | 1 | 37.43 |

| 11 | -1 | 1 | -1 | 1 | 40.1 |

| 12 | 1 | 1 | -1 | 1 | 36.1 |

| 13 | -1 | -1 | 1 | 1 | 44.98 |

| 14 | 1 | -1 | 1 | 1 | 42.53 |

| 15 | -1 | 1 | 1 | 1 | 43.58 |

| 16 | 1 | 1 | 1 | 1 | 41.75 |

| 17 | -1.719 | 0 | 0 | 0 | 35.18 |

| 18 | 1.719 | 0 | 0 | 0 | 39.29 |

| 19 | 0 | -1.719 | 0 | 0 | 45.13 |

| 20 | 0 | 1.719 | 0 | 0 | 42.55 |

| 21 | 0 | 0 | -1.719 | 0 | 39.5 |

| 22 | 0 | 0 | 1.719 | 0 | 37.92 |

| 23 | 0 | 0 | 0 | -1.719 | 27.85 |

| 24 | 0 | 0 | 0 | 1.719 | 42.2 |

| 25 | 0 | 0 | 0 | 0 | 38.43 |

| 26 | 0 | 0 | 0 | 0 | 38.52 |

| 27 | 0 | 0 | 0 | 0 | 36.73 |

| 28 | 0 | 0 | 0 | 0 | 37.93 |

| 29 | 0 | 0 | 0 | 0 | 35.88 |

| 30 | 0 | 0 | 0 | 0 | 38.58 |

Table 8 Design and results of soil-soil parameter calibration test

| 试验号 Number | 恢复 系数X1 | 静摩擦 系数X2 | 动摩擦 系数X3 | 表面能X4(J/m2) | 堆积角(°) |

|---|---|---|---|---|---|

| 1 | -1 | -1 | -1 | -1 | 33.82 |

| 2 | 1 | -1 | -1 | -1 | 44.08 |

| 3 | -1 | 1 | -1 | -1 | 38.18 |

| 4 | 1 | 1 | -1 | -1 | 32.92 |

| 5 | -1 | -1 | 1 | -1 | 33.4 |

| 6 | 1 | -1 | 1 | -1 | 31.02 |

| 7 | -1 | 1 | 1 | -1 | 31.35 |

| 8 | 1 | 1 | 1 | -1 | 52.39 |

| 9 | -1 | -1 | -1 | 1 | 45.2 |

| 10 | 1 | -1 | -1 | 1 | 37.43 |

| 11 | -1 | 1 | -1 | 1 | 40.1 |

| 12 | 1 | 1 | -1 | 1 | 36.1 |

| 13 | -1 | -1 | 1 | 1 | 44.98 |

| 14 | 1 | -1 | 1 | 1 | 42.53 |

| 15 | -1 | 1 | 1 | 1 | 43.58 |

| 16 | 1 | 1 | 1 | 1 | 41.75 |

| 17 | -1.719 | 0 | 0 | 0 | 35.18 |

| 18 | 1.719 | 0 | 0 | 0 | 39.29 |

| 19 | 0 | -1.719 | 0 | 0 | 45.13 |

| 20 | 0 | 1.719 | 0 | 0 | 42.55 |

| 21 | 0 | 0 | -1.719 | 0 | 39.5 |

| 22 | 0 | 0 | 1.719 | 0 | 37.92 |

| 23 | 0 | 0 | 0 | -1.719 | 27.85 |

| 24 | 0 | 0 | 0 | 1.719 | 42.2 |

| 25 | 0 | 0 | 0 | 0 | 38.43 |

| 26 | 0 | 0 | 0 | 0 | 38.52 |

| 27 | 0 | 0 | 0 | 0 | 36.73 |

| 28 | 0 | 0 | 0 | 0 | 37.93 |

| 29 | 0 | 0 | 0 | 0 | 35.88 |

| 30 | 0 | 0 | 0 | 0 | 38.58 |

| 堆积角 Angle of repose | 方差来源 Variance source | 平方和 Sum of squares | 自由度 Freedom | 均方 mean square | F 值 F value | P 值 P Value | |

|---|---|---|---|---|---|---|---|

| 模型 | 545 | 14 | 38.93 | 9.76 | <0.000 1 | ** | |

| X1 | 2.46 | 1 | 2.46 | 0.62 | 0.444 9 | ||

| X2 | 25.82 | 1 | 25.82 | 6.47 | 0.022 5 | * | |

| X3 | 3.72 | 1 | 3.72 | 0.93 | 0.349 6 | ||

| X4 | 282.24 | 1 | 282.24 | 70.75 | <0.000 1 | ** | |

| X1X2 | 0.037 | 1 | 0.037 | 9.289E-003 | 0.924 5 | ||

| X1X3 | 3.25 | 1 | 3.25 | 0.81 | 0.381 1 | ||

| X1X4 | 65.49 | 1 | 65.49 | 16.42 | 0.001 0 | ** | |

| X2X3 | 3.14 | 1 | 3.14 | 0.79 | 0.388 8 | ||

| X2X4 | 0.28 | 1 | 0.28 | 0.071 | 0.793 4 | ||

| X3X4 | 73.66 | 1 | 73.66 | 18.47 | 0.000 6 | ** | |

| X12 | 2.68 | 1 | 2.68 | 0.67 | 0.424 9 | ||

| X22 | 59.33 | 1 | 59.33 | 14.87 | 0.001 6 | ** | |

| X32 | 0.2 | 1 | 0.2 | 0.05 | 0.825 7 | ||

| X42 | 22.69 | 1 | 22.69 | 5.69 | 0.030 7 | * | |

| 残差 | 59.84 | 15 | 3.99 | ||||

| 失拟项 | 53.55 | 10 | 5.36 | 4.26 | 0.061 6 | ||

| 误差 | 6.28 | 5 | 1.26 | ||||

| 总和 | 604.84 | 29 |

Table 9 Analysis of variance of soil-soil parameter calibration test

| 堆积角 Angle of repose | 方差来源 Variance source | 平方和 Sum of squares | 自由度 Freedom | 均方 mean square | F 值 F value | P 值 P Value | |

|---|---|---|---|---|---|---|---|

| 模型 | 545 | 14 | 38.93 | 9.76 | <0.000 1 | ** | |

| X1 | 2.46 | 1 | 2.46 | 0.62 | 0.444 9 | ||

| X2 | 25.82 | 1 | 25.82 | 6.47 | 0.022 5 | * | |

| X3 | 3.72 | 1 | 3.72 | 0.93 | 0.349 6 | ||

| X4 | 282.24 | 1 | 282.24 | 70.75 | <0.000 1 | ** | |

| X1X2 | 0.037 | 1 | 0.037 | 9.289E-003 | 0.924 5 | ||

| X1X3 | 3.25 | 1 | 3.25 | 0.81 | 0.381 1 | ||

| X1X4 | 65.49 | 1 | 65.49 | 16.42 | 0.001 0 | ** | |

| X2X3 | 3.14 | 1 | 3.14 | 0.79 | 0.388 8 | ||

| X2X4 | 0.28 | 1 | 0.28 | 0.071 | 0.793 4 | ||

| X3X4 | 73.66 | 1 | 73.66 | 18.47 | 0.000 6 | ** | |

| X12 | 2.68 | 1 | 2.68 | 0.67 | 0.424 9 | ||

| X22 | 59.33 | 1 | 59.33 | 14.87 | 0.001 6 | ** | |

| X32 | 0.2 | 1 | 0.2 | 0.05 | 0.825 7 | ||

| X42 | 22.69 | 1 | 22.69 | 5.69 | 0.030 7 | * | |

| 残差 | 59.84 | 15 | 3.99 | ||||

| 失拟项 | 53.55 | 10 | 5.36 | 4.26 | 0.061 6 | ||

| 误差 | 6.28 | 5 | 1.26 | ||||

| 总和 | 604.84 | 29 |

| 参数Parameter | 数值The values |

|---|---|

| 土-土恢复系数 | 0.57 |

| Soil-65Mn Recovery coefficient | |

| 土-土静摩擦系数 | 0.65 |

| Soil-65MnStatic friction coefficient | |

| 土-土滚动摩擦系数 | 0.23 |

| Soil-65MnDynamic friction coefficient | |

| 土-土JKR表面能 | 4.49 |

| Soil-65MnJKR surface energy |

Table 10 Parameters of soil-soil contact model

| 参数Parameter | 数值The values |

|---|---|

| 土-土恢复系数 | 0.57 |

| Soil-65Mn Recovery coefficient | |

| 土-土静摩擦系数 | 0.65 |

| Soil-65MnStatic friction coefficient | |

| 土-土滚动摩擦系数 | 0.23 |

| Soil-65MnDynamic friction coefficient | |

| 土-土JKR表面能 | 4.49 |

| Soil-65MnJKR surface energy |

| 项目 Project | 仿真值 Simulation value | 实际值 Actual value | 相对误差 Relative error |

|---|---|---|---|

| 滚动距离Rolling distance(mm) | 241.05 | 227.29 | 6.05 |

| 堆积角Angle of repose(°) | 37.16 | 37.64 | 1.28 |

Table 11 comparison of test results

| 项目 Project | 仿真值 Simulation value | 实际值 Actual value | 相对误差 Relative error |

|---|---|---|---|

| 滚动距离Rolling distance(mm) | 241.05 | 227.29 | 6.05 |

| 堆积角Angle of repose(°) | 37.16 | 37.64 | 1.28 |

| 编号 Test | 作业速度 (km/h) | 仿真试验 结果(N) Simulation value | 田间试验 结果(N) Field experiment | 相对误差(%) Relative error |

|---|---|---|---|---|

| 1 | 8 | 787 9.28 | 832 7.46 | 5.69 |

| 2 | 9 | 809 3.18 | 857 4.41 | 5.95 |

| 3 | 10 | 886 4.49 | 944 0.16 | 6.49 |

Table 12 Resistance comparison

| 编号 Test | 作业速度 (km/h) | 仿真试验 结果(N) Simulation value | 田间试验 结果(N) Field experiment | 相对误差(%) Relative error |

|---|---|---|---|---|

| 1 | 8 | 787 9.28 | 832 7.46 | 5.69 |

| 2 | 9 | 809 3.18 | 857 4.41 | 5.95 |

| 3 | 10 | 886 4.49 | 944 0.16 | 6.49 |

| [1] | 黄昌永. 土壤学[M]. 北京: 中国农业出版社, 2010:156-157. |

| HUANG Changyong. Soil Science,3.[M]. Bei Jing: China Agricultural Press, 2010:156-157. | |

| [2] | 马君, 崔建平, 金亮, 等. 新疆滴灌棉田深松后土壤理化性质及产量的变化特征[J]. 中国农学通报, 2020, 36(32):82-87. |

| MA Jun, CUI Jianping,. JIN Liang, et al. Variation Characteristics of Soil Physical and Chemical Properties and Yield After Subsoiling in Drip Irrigated Cotton Fields in Xinjiang[J]. Chinese Agricultural Science Bulletin, 2020, 36(32):82-87. | |

| [3] | 虎胆•吐马尔白, 赵永成, 马合木江•艾合买提, 等. 北疆常年膜下滴灌棉田土壤盐分积累特征研究[J]. 灌溉排水学报, 2016, 35(1):1-5. |

| HUDAN•Wenmaerbai, ZHAO Yongcheng, MAHEMUJIANG•Aihemaiti, et al. Study on Characteristics of Cotton Field Soil Salt Accumulation under Perennial Mulched Drip Irrigation in Northern Xinjiang[J]. Journal of Irrigation and Drainage, 2016, 35(1):1-5. | |

| [4] | 薛忠, 赵亮, 王凤花, 等. 基于EDEM的螺旋式排肥器排肥性能研究[J]. 农机化研究, 2020, 42(6):87-95. |

| XUE Zhong, ZHAO Liang, WANG Fenghua, et al. Study on the Performance of Spiral Fertilizer Distributor Based on EDEM[J]. Journal of Agricultural Mechanization Research, 2020, 42(6):87-95. | |

| [5] | 马晨, 蒙贺伟, 坎杂, 等. 葡萄深施有机肥开沟装置设计及仿真[J]. 农机化研究, 2019, 41(12):7-13,21. |

| MA Chen, MENG Hewei, KAN Za, et al. Design and Simulation of Deep Application of Organic Fertilizer Ditching Device for Grape[J]. Journal of Agricultural Mechanization Research, 2019, 41(12):7-13,21. | |

| [6] | 何永强, 贺俊林, 杨作梅. 犁体曲面离散元仿真试验与参数优化[J]. 农机化研究, 2019, 41(12):189-193+257. |

| HE Yongqiang, HE Junlin, YANG Zuomei, et al. Discrete Element Simulation and Parameter Optimization of Plow Surface[J]. Journal of Agricultural Mechanization Research, 2019, 41(12):189-193+257. | |

| [7] | 何晓宁, 张学军, 赵壮, 等. 基于离散元法的油莎豆降阻挖掘装置设计与试验[J]. 农业机械学报, 2021, 52(12):124-133. |

| HE Xiaoning, ZHANG Xuejun, ZHAO Zhuang, et al. Design and Test of Resistance-reducing Excavation Device of Cyperus edulis Based on Discrete Element Method[J]. Transactions of the Chinese Society for Agricultural Machinery, 2021, 52(12):124-133. | |

| [8] | 赵淑红, 刘汉朋, 侯磊涛, 等. 基于离散元法的免耕深施肥分段式玉米播种开沟器研制[J]. 农业工程学报, 2021, 37(13):1-10. |

| ZHAO Shuhong, LIU Hanpeng, HOU Leitao, et al. Development of deep fertilizing no-segmented maize sowing opener using discrete element method[J]. Transactions of the Chinese Society of Agricultural Engineering, 2021, 37(13):1-10. | |

| [9] | Bo Li, Ying Chen, Jun Chen. Modeling of soil-claw interaction using the discrete element method(DEM)[J]. Soil&Tillage Research, 2016, 158:177-185. |

| [10] |

Zhiwei Zeng, Ying Chen. Simulation of straw movement by discrete element modelling of straw-sweep-soil interaction[J]. Biosystems Engineering, 2019, 180:25-35.

DOI |

| [11] | Rongqing Liang, Xuegeng Chen, Peng Jiang, et al. Calibration of the simulation parameters of the particulate materials in film mixed materials[J]. International Journal of Agricultural and Biological Engineering, 2020, 13(4):29-36. |

| [12] | 戴飞, 宋学锋, 赵武云, 等. 全膜双垄沟覆膜土壤离散元接触参数仿真标定[J]. 农业机械学报, 2019, 50(2):49-56. |

| DAI Fei, SONG Xuefeng, ZHAO Wuyun, et al. Simulative Calibration on Contact Parameters of Discrete Elements for Covering Soil on Whole Plastic Film Mulching on Double Ridges[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(2):49-56. | |

| [13] | 谢方平, 吴正阳, 王修善, 等. 基于无侧限抗压强度试验的土壤离散元参数标定[J]. 农业工程学报, 2020, 36(13):39-47. |

| XIE Fangping, WU Zhengyang, WANG Xiushan, et al. Calibration of Discrete Element Parameters of Soils Based on Unconfined Compressive Strength Test[J]. Transactions of the Chinese Society of Agricultural Engineering, 2020, 36(13):39-47. | |

| [14] | 赵淑红, 刘汉朋, 杨超, 等. 玉米秸秆还田交互式分层深松铲设计与离散元仿真[J]. 农业机械学报, 2021, 52(3):75-87. |

| ZHAO Shuhong, LIU Hanpeng, YANG Chao, et al. Design and Discrete Element Simulation of Interactive Layered Subsoiler with Maize Straw Returned to Filed[J]. Transactions of the Chinese Society for Agricultural Machinery, 2021, 52(3):75-87. | |

| [15] | 田辛亮, 丛旭, 齐江涛, 等. 黑土区玉米秸秆-土壤混料离散元模型参数标定[J]. 农业机械学报, 2021, 52(10):100-108,242. |

| TIAN Xinliang, CONG Xu, QI Jiangtao, et al. Parameter Calibration of Discrete Element Model for Corn Straw and Soil Mixture in Black Soil Areas[J]. Transactions of the Chinese Society for Agricultural Machinery, 2021, 52(10):100-108,242. | |

| [16] |

Mohsin Ajmal, Thomas Roessler, Christian Richter, André Katterfeld. Calibration of cohesive DEM parameters under rapid flow conditions and low consolidation stresses[J]. Powder Technology, 2020, 374:22-32.

DOI URL |

| [17] |

Rui Xia, Bo Li, Xuewen Wang, Tiejun Li, Zhaojian Yang. Measurement and calibration of the discrete element parameters of wet bulk coal[J]. Measurement, 2019, 142:84-95.

DOI |

| [18] | Lyu Jaehee, Park Junyoung. Analysis of Particle Packing Process by Contact Model in Discrete Element Method[J]. The Korean Society of Manufacturing Process Engineers, 2019, 18(3):56-65. |

| [19] |

Sheng Chen, Wenwei Liu, Shuiqing Li. A fast adhesive discrete element method for random packings of fine particles[J]. Chemical Engineering Science, 2019, 193:346-345.

DOI URL |

| [20] | 李俊伟, 佟金, 胡斌, 等. 不同含水率黏重黑土与触土部件互作的离散元仿真参数标定[J]. 农业工程学报, 2019, 35(6):130-140. |

| LI Junwei, TONG Jin, HU Bin, et al. Calibration of Parameters of Interaction between Clayey Black Soil with Different Moisture Content and Soil-engaging Component in Northeast China[J]. Transactions of the Chinese Society of Agricultural Engineering, 2019, 35(6):130-140. | |

| [21] | 马帅, 徐丽明, 袁全春, 等. 葡萄藤防寒土与清土部件相互作用的离散元仿真参数标定[J]. 农业工程学报, 2020, 36(1):40-49. |

| MA Shuai, XU Liming, YUAN Quanchun, et al. Calibration of Discrete Element Simulation Parameters of Grapevine Antifreezing Soil and Its Interaction with Soil-cleaning Components[J]. Transactions of the Chinese Society of Agricultural Engineering, 2020, 36(1):40-49. | |

| [22] | 王宪良, 胡红, 王庆杰, 等. 基于离散元的土壤模型参数标定方法[J]. 农业机械学报, 2017, 48(12):78-85. |

| WANG Xianliang, HU Hong, WANG Qingjie, et al. Calibration Method of Soil Contact Characteristic Parameters Based on DEM Theory[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(12):78-85. |

| No related articles found! |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||