Xinjiang Agricultural Sciences ›› 2024, Vol. 61 ›› Issue (10): 2514-2526.DOI: 10.6048/j.issn.1001-4330.2024.10.019

• Plant Protection · Soil Fertilizer · Water Saving Irrigation · Agricultural Equipment Engineering and Mechanization · Prataculture • Previous Articles Next Articles

ZHOU Yan1( ), HE Lei1(

), HE Lei1( ), SONG Long1, PAN Yunfei2, WANG Qiang2, SONG Zhenshuai2

), SONG Long1, PAN Yunfei2, WANG Qiang2, SONG Zhenshuai2

Received:2023-11-02

Online:2024-10-20

Published:2024-11-07

Correspondence author:

HE Lei

Supported by:

周艳1( ), 何磊1(

), 何磊1( ), 宋龙1, 潘云飞2, 王强2, 宋振帅2

), 宋龙1, 潘云飞2, 王强2, 宋振帅2

通讯作者:

何磊

作者简介:周艳(1970-),女,四川大竹人,研究员,博士,硕士生导师,研究方向为农业机械化,(E-mail) zhouyan683886@sina.com

基金资助:CLC Number:

ZHOU Yan, HE Lei, SONG Long, PAN Yunfei, WANG Qiang, SONG Zhenshuai. Design and experiment of self-propelled track flower-thinning machine in orchards[J]. Xinjiang Agricultural Sciences, 2024, 61(10): 2514-2526.

周艳, 何磊, 宋龙, 潘云飞, 王强, 宋振帅. 果园履带自走式疏花机的设计与试验[J]. 新疆农业科学, 2024, 61(10): 2514-2526.

| 项目 Project | 数值 The numerical |

|---|---|

| 总机尺寸(长×宽×高) Size of switchboard (L×W×H)(m) | 2.2×1.7×3.5 |

| 配套履带拖拉机动力 Supporting crawler tractor power(KW) | 30~50 |

| 整机自重 The whole weight of(kg) | 800 |

| 作业速度 Operating speed (km/h) | 1 |

| 作业幅宽 Operating range of(m) | 1 |

| 液压系统工作压力 Working pressure of hydraulic system(MPa) | 10 |

| 拟定初选液压泵的转速 Formulate the primary hydraulic pump speed (r/min) | 200~2 000 |

| 疏花轴作业高度 Working height of sparse axis(m) | 3 900 |

Tab.1 main technical parameters of orchard caterpillar flower thinning machine

| 项目 Project | 数值 The numerical |

|---|---|

| 总机尺寸(长×宽×高) Size of switchboard (L×W×H)(m) | 2.2×1.7×3.5 |

| 配套履带拖拉机动力 Supporting crawler tractor power(KW) | 30~50 |

| 整机自重 The whole weight of(kg) | 800 |

| 作业速度 Operating speed (km/h) | 1 |

| 作业幅宽 Operating range of(m) | 1 |

| 液压系统工作压力 Working pressure of hydraulic system(MPa) | 10 |

| 拟定初选液压泵的转速 Formulate the primary hydraulic pump speed (r/min) | 200~2 000 |

| 疏花轴作业高度 Working height of sparse axis(m) | 3 900 |

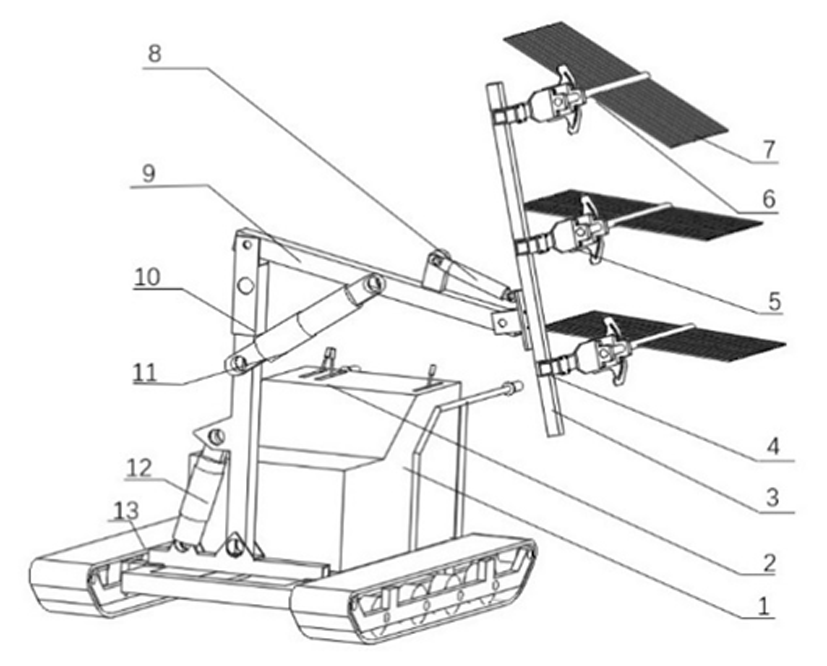

Fig.2 Schematic diagram of crawler type flower dredging machine Note:1.The control box;2.The joystick;3.Hydrophobic flower arm 1;4.Support;5.Slide to guide rail;6.Drain the rachis;7.Strip;8.The hydraulic cylinder1;9.Hydrophobic flower arm 2;10.Hydrophobic flower arm 3;11.The hydraulic cylinder2;12.The hydraulic cylinder 3;13.Crawler tractor

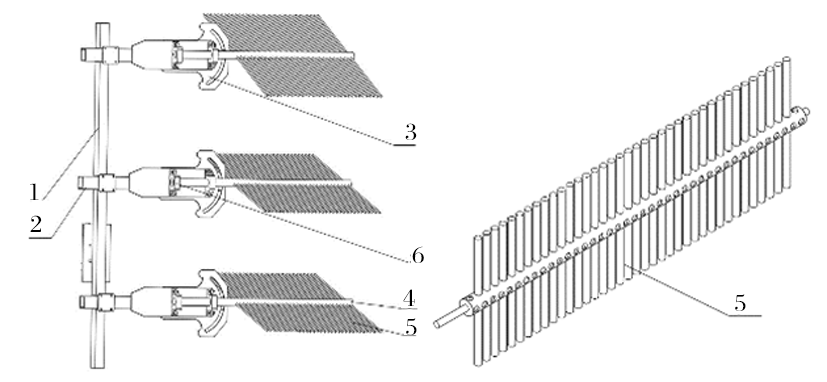

Fig.4 Sparser (left) sparser axis (right) Notes:3.Hydrophobic flower arm;4.stents;5.Slide to guide rail;6.Hydrophobic rachis;7.Strip;14.Hydraulic motor

| 类型 Type | 叶片马达 Leaf blade motor |

|---|---|

| 型号Model | YM |

| 额定压力The rated pressure(MPa) | 6MPa |

| 转速Speed(r/min) | 100~2000 r/min |

| 排量Displacement(mL/r) | 16.3~93.5 mL/r |

| 输出转矩The output torque(N) | 11~72 |

Tab.2 Hydraulic motor parameters

| 类型 Type | 叶片马达 Leaf blade motor |

|---|---|

| 型号Model | YM |

| 额定压力The rated pressure(MPa) | 6MPa |

| 转速Speed(r/min) | 100~2000 r/min |

| 排量Displacement(mL/r) | 16.3~93.5 mL/r |

| 输出转矩The output torque(N) | 11~72 |

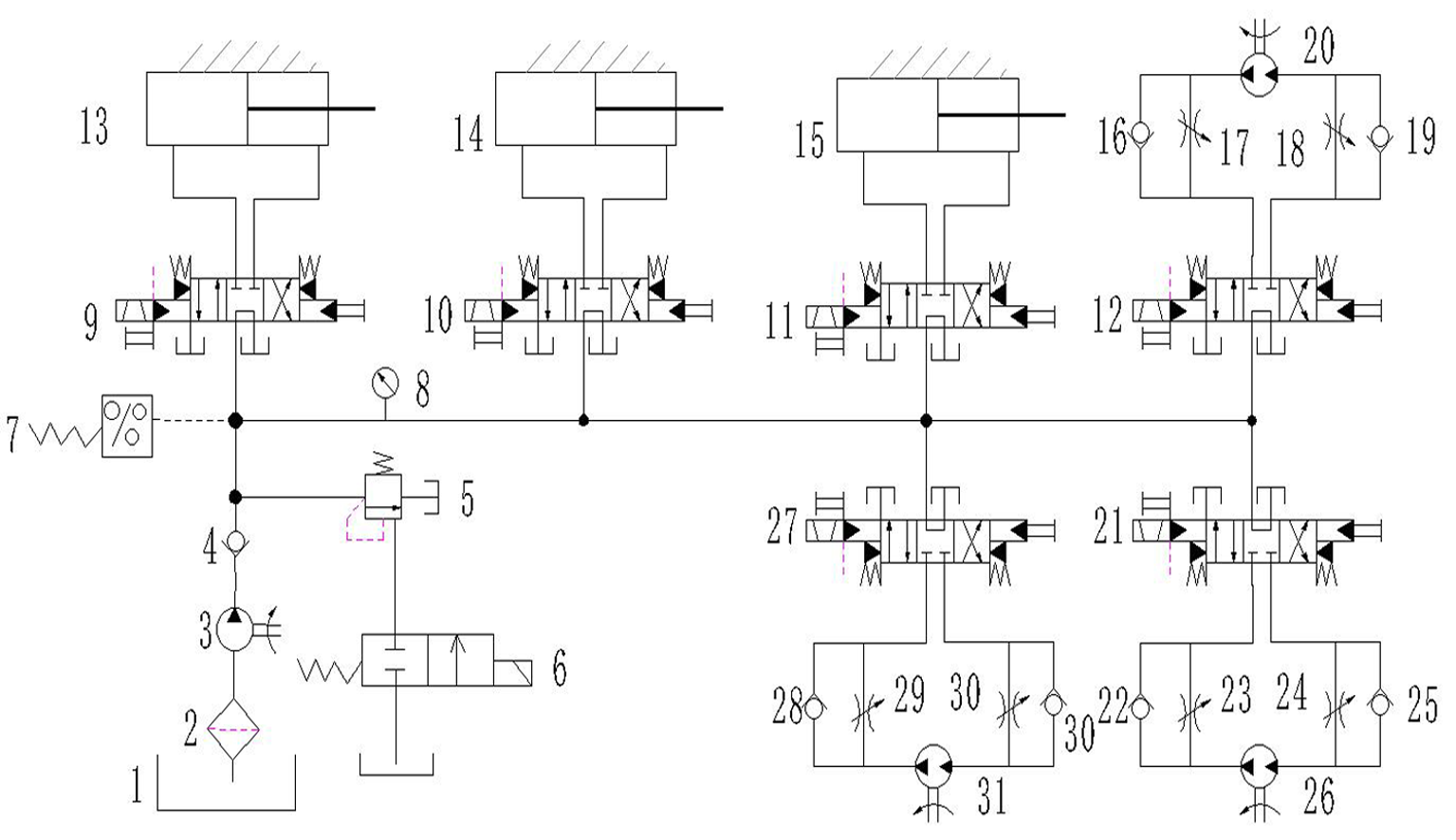

Fig.9 Schematic diagram of hydraulic system Note:1.The fuel tank; 2.Oil filter; 3.Quantitative pump; 4.Check valve;5.Overflow valve; 6.Solenoid valve; 7.Pressure relay; 8.Pressure gauge; 9,10,11,12,21,27 three four-way direction control valve; 13,14,15 double acting hydraulic cylinders; 16,19,22,25,28,30 check valve; 17,18,23,24,29,30adjustable throttle valve; 20,26,31Quantitative motor

| 水平 The level of | 行进速度 speed(km/h) | 胶条转速 Strip speed (r/min) | 胶条间隔 Strip interval (cm) |

|---|---|---|---|

| a | 2 | 200~300 | 3 |

| b | 3 | 300~400 | 4 |

| c | 4 | 300~400 | 5 |

| 350~400 |

Tab.3 Experimental factors and levels

| 水平 The level of | 行进速度 speed(km/h) | 胶条转速 Strip speed (r/min) | 胶条间隔 Strip interval (cm) |

|---|---|---|---|

| a | 2 | 200~300 | 3 |

| b | 3 | 300~400 | 4 |

| c | 4 | 300~400 | 5 |

| 350~400 |

| 作业前 花朵数(a)(朵) Number of flowers before homework (a) (flower) | 作业后 花朵数(b)(朵) Number of flowers after homework (b) (flower) | 疏除率(c) Hydrophobic besides rate (c) (%) |

|---|---|---|

| 27 | 23 | 13 |

| 32 | 27 | 17 |

| 33 | 29 | 12 |

| 30 | 26 | 13 |

| 32 | 28 | 14 |

| 26 | 22 | 16 |

| 21 | 17 | 19 |

| 34 | 30 | 11 |

| 43 | 38 | 12 |

| 33 | 29 | 11 |

| 38 | 32 | 14 |

| 39 | 32 | 16 |

| 41 | 34 | 17 |

| 27 | 23 | 13 |

| 37 | 31 | 15 |

| 32 | 28 | 11 |

| 49 | 39 | 20 |

Tab.4 Data under the condition of test B

| 作业前 花朵数(a)(朵) Number of flowers before homework (a) (flower) | 作业后 花朵数(b)(朵) Number of flowers after homework (b) (flower) | 疏除率(c) Hydrophobic besides rate (c) (%) |

|---|---|---|

| 27 | 23 | 13 |

| 32 | 27 | 17 |

| 33 | 29 | 12 |

| 30 | 26 | 13 |

| 32 | 28 | 14 |

| 26 | 22 | 16 |

| 21 | 17 | 19 |

| 34 | 30 | 11 |

| 43 | 38 | 12 |

| 33 | 29 | 11 |

| 38 | 32 | 14 |

| 39 | 32 | 16 |

| 41 | 34 | 17 |

| 27 | 23 | 13 |

| 37 | 31 | 15 |

| 32 | 28 | 11 |

| 49 | 39 | 20 |

| 作业前 花朵数(a)(朵) Number of flowers before homework (a) (flower) | 作业后 花朵数(b)(朵) Number of flowers after homework (b) (flower) | 疏除率(c) Hydrophobic besides rate (c)(%) |

|---|---|---|

| 37 | 25 | 32 |

| 29 | 25 | 35 |

| 41 | 26 | 36 |

| 43 | 27 | 37 |

| 28 | 17 | 39 |

| 34 | 23 | 31 |

| 38 | 25 | 36 |

| 32 | 22 | 30 |

| 33 | 22 | 33 |

| 39 | 24 | 37 |

| 41 | 26 | 35 |

| 30 | 20 | 32 |

| 28 | 18 | 33 |

| 24 | 17 | 30 |

| 49 | 33 | 33 |

| 32 | 21 | 34 |

| 35 | 23 | 35 |

Tab.5 Data under the condition of test B

| 作业前 花朵数(a)(朵) Number of flowers before homework (a) (flower) | 作业后 花朵数(b)(朵) Number of flowers after homework (b) (flower) | 疏除率(c) Hydrophobic besides rate (c)(%) |

|---|---|---|

| 37 | 25 | 32 |

| 29 | 25 | 35 |

| 41 | 26 | 36 |

| 43 | 27 | 37 |

| 28 | 17 | 39 |

| 34 | 23 | 31 |

| 38 | 25 | 36 |

| 32 | 22 | 30 |

| 33 | 22 | 33 |

| 39 | 24 | 37 |

| 41 | 26 | 35 |

| 30 | 20 | 32 |

| 28 | 18 | 33 |

| 24 | 17 | 30 |

| 49 | 33 | 33 |

| 32 | 21 | 34 |

| 35 | 23 | 35 |

| 作业前 花朵数(a)(朵) Number of flowers before homework (a) (flower) | 作业后 花朵数(b)(朵) Number of flowers after homework (b) (flower) | 疏除率(c) Hydrophobic besides rate (c) (%) |

|---|---|---|

| 23 | 14 | 37 |

| 29 | 18 | 39 |

| 32 | 18 | 43 |

| 42 | 24 | 42 |

| 47 | 28 | 40 |

| 38 | 25 | 35 |

| 33 | 21 | 35 |

| 18 | 12 | 34 |

| 23 | 15 | 38 |

| 32 | 19 | 40 |

| 42 | 27 | 36 |

| 25 | 16 | 37 |

| 19 | 12 | 35 |

| 33 | 21 | 36 |

| 35 | 22 | 36 |

| 41 | 25 | 39 |

| 29 | 18 | 37 |

Tab.6 Data under the condition of test C

| 作业前 花朵数(a)(朵) Number of flowers before homework (a) (flower) | 作业后 花朵数(b)(朵) Number of flowers after homework (b) (flower) | 疏除率(c) Hydrophobic besides rate (c) (%) |

|---|---|---|

| 23 | 14 | 37 |

| 29 | 18 | 39 |

| 32 | 18 | 43 |

| 42 | 24 | 42 |

| 47 | 28 | 40 |

| 38 | 25 | 35 |

| 33 | 21 | 35 |

| 18 | 12 | 34 |

| 23 | 15 | 38 |

| 32 | 19 | 40 |

| 42 | 27 | 36 |

| 25 | 16 | 37 |

| 19 | 12 | 35 |

| 33 | 21 | 36 |

| 35 | 22 | 36 |

| 41 | 25 | 39 |

| 29 | 18 | 37 |

| 作业前 花朵数(a)(朵) Number of flowers before homework (a) (flower) | 作业后 花朵数(b)(朵) Number of flowers after homework (b) (flower) | 疏除率(c) Hydrophobic besides rate (c) (%) |

|---|---|---|

| 33 | 26 | 21 |

| 35 | 26 | 27 |

| 27 | 19 | 28 |

| 26 | 20 | 24 |

| 32 | 25 | 22 |

| 41 | 30 | 26 |

| 38 | 30 | 21 |

| 36 | 29 | 19 |

| 25 | 19 | 22 |

| 27 | 20 | 24 |

| 32 | 26 | 18 |

| 39 | 29 | 25 |

| 33 | 24 | 29 |

| 34 | 24 | 30 |

| 23 | 18 | 23 |

| 45 | 34 | 25 |

| 39 | 29 | 25 |

Tab.7 Data under the condition of test D

| 作业前 花朵数(a)(朵) Number of flowers before homework (a) (flower) | 作业后 花朵数(b)(朵) Number of flowers after homework (b) (flower) | 疏除率(c) Hydrophobic besides rate (c) (%) |

|---|---|---|

| 33 | 26 | 21 |

| 35 | 26 | 27 |

| 27 | 19 | 28 |

| 26 | 20 | 24 |

| 32 | 25 | 22 |

| 41 | 30 | 26 |

| 38 | 30 | 21 |

| 36 | 29 | 19 |

| 25 | 19 | 22 |

| 27 | 20 | 24 |

| 32 | 26 | 18 |

| 39 | 29 | 25 |

| 33 | 24 | 29 |

| 34 | 24 | 30 |

| 23 | 18 | 23 |

| 45 | 34 | 25 |

| 39 | 29 | 25 |

| 作业前 花朵数(a)(朵) Number of flowers before homework (a) (flower) | 作业后 花朵数(b)(朵) Number of flowers after homework (b) (flower) | 疏除率(c) Hydrophobic besides rate (c) (%) |

|---|---|---|

| 19 | 13 | 33 |

| 36 | 24 | 32 |

| 47 | 33 | 30 |

| 39 | 28 | 29 |

| 42 | 32 | 25 |

| 28 | 19 | 32 |

| 33 | 21 | 38 |

| 35 | 21 | 39 |

| 43 | 29 | 33 |

| 27 | 17 | 35 |

| 39 | 27 | 31 |

| 32 | 22 | 30 |

| 29 | 19 | 35 |

| 38 | 27 | 29 |

| 42 | 28 | 33 |

| 27 | 18 | 34 |

| 30 | 20 | 33 |

Tab.8 Data under the condition of test E

| 作业前 花朵数(a)(朵) Number of flowers before homework (a) (flower) | 作业后 花朵数(b)(朵) Number of flowers after homework (b) (flower) | 疏除率(c) Hydrophobic besides rate (c) (%) |

|---|---|---|

| 19 | 13 | 33 |

| 36 | 24 | 32 |

| 47 | 33 | 30 |

| 39 | 28 | 29 |

| 42 | 32 | 25 |

| 28 | 19 | 32 |

| 33 | 21 | 38 |

| 35 | 21 | 39 |

| 43 | 29 | 33 |

| 27 | 17 | 35 |

| 39 | 27 | 31 |

| 32 | 22 | 30 |

| 29 | 19 | 35 |

| 38 | 27 | 29 |

| 42 | 28 | 33 |

| 27 | 18 | 34 |

| 30 | 20 | 33 |

| 作业前 花朵数(a)(朵) Number of flowers before homework (a) (flower) | 作业后 花朵数(b)(朵) Number of flowers after homework (b) (flower) | 疏除率(c) Hydrophobic besides rate (c) (%) |

|---|---|---|

| 43 | 25 | 43 |

| 38 | 22 | 43 |

| 37 | 22 | 42 |

| 45 | 27 | 41 |

| 36 | 22 | 39 |

| 28 | 18 | 37 |

| 33 | 19 | 42 |

| 39 | 22 | 43 |

| 41 | 23 | 45 |

| 40 | 24 | 39 |

| 46 | 28 | 40 |

| 32 | 18 | 45 |

| 29 | 15 | 47 |

| 27 | 16 | 42 |

| 33 | 19 | 41 |

| 35 | 20 | 42 |

| 37 | 19 | 49 |

Tab.9 Data under the condition of test F

| 作业前 花朵数(a)(朵) Number of flowers before homework (a) (flower) | 作业后 花朵数(b)(朵) Number of flowers after homework (b) (flower) | 疏除率(c) Hydrophobic besides rate (c) (%) |

|---|---|---|

| 43 | 25 | 43 |

| 38 | 22 | 43 |

| 37 | 22 | 42 |

| 45 | 27 | 41 |

| 36 | 22 | 39 |

| 28 | 18 | 37 |

| 33 | 19 | 42 |

| 39 | 22 | 43 |

| 41 | 23 | 45 |

| 40 | 24 | 39 |

| 46 | 28 | 40 |

| 32 | 18 | 45 |

| 29 | 15 | 47 |

| 27 | 16 | 42 |

| 33 | 19 | 41 |

| 35 | 20 | 42 |

| 37 | 19 | 49 |

| 序号 The serial number | 前进 速度 Forward speed (Km/h) | 胶条 转速 Speed of the rubber strip (r/min) | 胶条 间隔 Rubber strip spacing (cm) | 疏除率 Hydrophobic rate (%) | 平均 疏除率 Mean thinning rate (%) |

|---|---|---|---|---|---|

| A | 2 | 200~300 | 3 | 10~20 | 14.35 |

| B | 3 | 300~400 | 4 | 30~40 | 34.01 |

| C | 4 | 300~400 | 4 | 35~45 | 37.58 |

| D | 4 | 300~400 | 5 | 20~28 | 24.05 |

| E | 3 | 300~400 | 5 | 29~35 | 32.41 |

| F | 3 | 350~400 | 5 | 40~45 | 42.35 |

Tab.10 Experimental design scheme and response value

| 序号 The serial number | 前进 速度 Forward speed (Km/h) | 胶条 转速 Speed of the rubber strip (r/min) | 胶条 间隔 Rubber strip spacing (cm) | 疏除率 Hydrophobic rate (%) | 平均 疏除率 Mean thinning rate (%) |

|---|---|---|---|---|---|

| A | 2 | 200~300 | 3 | 10~20 | 14.35 |

| B | 3 | 300~400 | 4 | 30~40 | 34.01 |

| C | 4 | 300~400 | 4 | 35~45 | 37.58 |

| D | 4 | 300~400 | 5 | 20~28 | 24.05 |

| E | 3 | 300~400 | 5 | 29~35 | 32.41 |

| F | 3 | 350~400 | 5 | 40~45 | 42.35 |

| 方差来源 Source | 果树疏除率 Thinning rate of fruit trees | |||

|---|---|---|---|---|

| 平方和 Sum of squares | 自由度 Degrees of freedom | F | 显著水平 Significant level | |

| 模型 Mesidual | 43.38 | 9 | 13.50 | <0.001 2 |

| X1 | 4.50 | 1 | 12.60 | 0.000 93 |

| X2 | 18.00 | 1 | 50.40 | 0.000 2 |

| X3 | 0.001 | 1 | 0.001 | 1.000 0 |

| X1X2 | 1 | 1 | 2.80 | 0.138 2 |

| X1X3 | 0.000 | 1 | 0.000 | 1.000 0 |

| X2X3 | 1 | 1 | 2.80 | 0.138 2 |

| 6.58 | 1 | 18.42 | 0.003 6 | |

| 12.89 | 1 | 36.11 | 0.000 5 | |

| 0.26 | 1 | 0.74 | 0.419 1 | |

| 残差 Residual | 2.50 | 7 | ||

| 失拟项 Lack of fit | 0.50 | 3 | 0.33 | 0.803 2 |

| 误差 Pure error | 2.00 | 4 | ||

| 总和 Total | 45.88 | 16 | ||

Tab.11 Analysis of variance of regression equation

| 方差来源 Source | 果树疏除率 Thinning rate of fruit trees | |||

|---|---|---|---|---|

| 平方和 Sum of squares | 自由度 Degrees of freedom | F | 显著水平 Significant level | |

| 模型 Mesidual | 43.38 | 9 | 13.50 | <0.001 2 |

| X1 | 4.50 | 1 | 12.60 | 0.000 93 |

| X2 | 18.00 | 1 | 50.40 | 0.000 2 |

| X3 | 0.001 | 1 | 0.001 | 1.000 0 |

| X1X2 | 1 | 1 | 2.80 | 0.138 2 |

| X1X3 | 0.000 | 1 | 0.000 | 1.000 0 |

| X2X3 | 1 | 1 | 2.80 | 0.138 2 |

| 6.58 | 1 | 18.42 | 0.003 6 | |

| 12.89 | 1 | 36.11 | 0.000 5 | |

| 0.26 | 1 | 0.74 | 0.419 1 | |

| 残差 Residual | 2.50 | 7 | ||

| 失拟项 Lack of fit | 0.50 | 3 | 0.33 | 0.803 2 |

| 误差 Pure error | 2.00 | 4 | ||

| 总和 Total | 45.88 | 16 | ||

| 项目 Items | 疏除率 Hydrophobic besides the rate(%) |

|---|---|

| 理论优化值 Theoretical optimum value | 35~40 |

| 第 1 次试验 First test value | 34~38 |

| 第2次试验 Second test value | 36~42 |

| 第 3 次试验 Third test value | 35~40 |

| 平均值 Average value | 35.33~40 |

| 相对误差 Relative error(%) | ≤4 |

Tab.12 Test validation values

| 项目 Items | 疏除率 Hydrophobic besides the rate(%) |

|---|---|

| 理论优化值 Theoretical optimum value | 35~40 |

| 第 1 次试验 First test value | 34~38 |

| 第2次试验 Second test value | 36~42 |

| 第 3 次试验 Third test value | 35~40 |

| 平均值 Average value | 35.33~40 |

| 相对误差 Relative error(%) | ≤4 |

| [1] | 苹果产业技术体系. 果产业经济发展年度报告[R]. 北京: 农业部苹果产业经济研究室, 2018. |

| Apple Industrial Technology System. Annual Report on Economic Development of fruit industry[R]. Beijing: Research Office of Apple Industry Economy, Ministry of Agriculture, 2018. | |

| [2] | 佚名. 我国水果产业发展状况及柑橘产销形势分析[J]. 果农之友, 2011,(1): 3-5. |

| Unknown author. Analysis on the development status of China's fruit industry and the situation of citrus production and marketing[J]. Fruit Growers’ Friends, 2011,(1): 3-5. | |

| [3] | 赵鹏飞, 邵建柱, 孙建设. 现代化苹果园的技术构成与益分析[D]. 保定: 河北农业大学, 2015. |

| ZHAO Pengfei, SHAO Jianzhu, SUN Jianshe. Technical structure and benefit analysis of modern apple orchards[D]. Baoding: Agricultural University of Hebei, 2015. | |

| [4] | 薛晓敏, 王金政, 丛培建, 等. 苹果花果管理技术研究进[J]. 江西农业学报, 2013, 25(12): 36-39. |

| XUE Xiaomin, WANG Jinzheng, CONG Peijian, et al. Research advances in flower and fruit management for apple tree[J]. Acta Agriculturae Jiangxi, 2013, 25(12): 36-39. | |

| [5] | 王学府, 孟玉平, 曹秋芬, 等. 苹果化学疏花疏果研究进展[J]. 果树学报, 2006, 23(3): 437-441. |

| WANG Xuefu1 MENG Yuping, CAO Qiufen, et al. Advances in research on chemical thinning for apple trees[J]. Journal of Fruit Science, 2006, 23(3): 437-441. | |

| [6] | 苏红波, 郭新宇, 陆声链, 等. 苹果花序几何造型及可视化研究[J]. 中国农学通报, 2009, 25(2): 272-276. |

| SU Hongbo, GUO Xinyu, LU Shenglian, et al. The Study for agriculture machinery vision guidance system technique[J]. Chinese Agricultural Science Bulletin, 2009, 25(2): 272-276. | |

| [7] | Martin-Gorriz B, Torregrosa A, Brunton J G. Feasibility of peach bloom thinning with hand-held mechanical devices[J]. Scientia Horticulturae, 2011, 129(1): 91-97. |

| [8] | Mcclure K A, Cline J A. Mechanical blossom thinning of apples and influence on yield, fruit quality and spur leaf area[J]. Canadian Journal of Plant Science, 2014, 95(5): 150608044237005. |

| [9] | Schupp J R, Baugher T A, Miller S S, et al. Mechanical Thinning of Peach and Apple Trees Reduces Labor Input and Increases Fruit Size[J]. Hort Technology, 2008, 18(4): 660-670. |

| [10] | Assirelli A, Giovannini D, Cacchi M, et al. Evaluation of a New Machine for Flower and Fruit Thinning in Stone Fruits[J]. Sustainability, 2018, 10(11). |

| [11] | 102217492. 便于手调作业高度与角度的电动疏花疏果机及其使用方法[P]. |

| 102217492. Southern Agricultural University. An electric flower thinning and fruit thinning machine convenient for manual adjustment of working height and Angle and its application method[P]. | |

| [12] | 李君, 陆华忠, 杨洲, 等. 荔枝柔性疏花器设计与试验研究[J]. 华南农业大学学报, 2013, 34(3): 431-435. |

| LI Jun, LU Huazhong, YANG Zhou, et al. Design and experimental study of litchi flexible thinning mechanism[J]. Journal of South China Agricultural University, 2013, 34(3): 431-435. | |

| [13] | 汪强. 矮密果树疏花装置设计及研究[D]. 保定: 河北农业大学, 2018. |

| WANG Qiang. Design and research of mechanical blossom thinning device for the dwarf dense fruit trees[D]. Baoding: Agricultural University of Hebei, 2018. | |

| [14] | 雷晓晖, 吕晓兰, 张美娜, 等. 电动甩绳式疏花装置在翠冠梨园中的试验研究[J]. 中国农机化学报, 2020, 41(9): 47-52. |

| LEI Xiaohui, LV Xiaolan, ZHANG Meina, et al. Test and research on electric rotating rope blossom thinner in‘Cuiguan’pear orchard[J]. Journal of Chinese Agricultural Mechanization, 2020, 41(9): 47-52. | |

| [15] | 胡彩旗, 孙传海, 纪晶. 果树机械疏花装置执行机构性能试验研究与分析[J]. 中国农机化学报, 2015, 36(5): 24-28. |

| HU Caiqi, SUN chuanhai, JI Jing. Performance experiment and analysis on mechanical thinning flower actuator[J]. Journal of Chinese Agricultural Mechanization, 2015, 36(5): 24-28. | |

| [16] | 孙传海, 胡彩旗, 侯庆松, 等. 基于ADAMS的机械柔性疏花装置执行机构仿真分析[J]. 农机化研究, 2015, 37(12): 70-73. |

| SUN Chuanhai, HU Caiqi, HOU Qingsong, et al. Simulation of mechanical thinning flower actuator based on ADAMS[J]. Journal of Agricultural Mechanization Research, 2015, 37(12): 70-73. | |

| [17] | 陈国帅, 陈艳艳, 罗红卫, 等. 不同花穗疏剪方法对桂味荔枝花果发育的影响[J]. 中国热带农业, 2017,(1): 65-68,45. |

| CHEN Guoshuai, CHEN Yanyan, LUO Hongwei, et al. Effect of different flower ear thinning methods on fruit development of Mandarin litchi[J]. China Tropical Agriculture, 2017,(1): 65-68,45. | |

| [18] | 聂佩显, 路超, 薛晓敏, 等. 不同时期一次性疏花疏果对苹果花序坐果率和果实品质的影响[J]. 河北农业科学, 2013, 17(2): 27-29. |

| NIE Peixian, LU Chao, XUE Xiaomin, et al. Effects of one-time-thinning flowers and fruits of different periods on fruit setting rate and fruit quality of apple[J]. Journal of Hebei Agricultural Sciences, 2013, 17(2): 27-29. | |

| [19] | Schupp J R, Kon, et al. Mechanical Blossom Thinning of 'GoldRush'/M.9 Apple Trees with Two String Types and Two Timings[J]. Journal American Pomological Society, 2014, 2014, 68(1): 24-31. |

| [20] | Solomakhin A A, Blanke M M. Mechanical flower thinning improves the fruit quality of apples[J]. Journal of the Science of Food and Agriculture, 2010, 90(5). |

| [21] | Impact of a mechanical flower thinning on growth, yield, diseases and fruit quality of sweet cherries (Prunus avium L.) under organic growing conditions[J]. Biological Agriculture and Horticulture, 2014, 30(1): 24-31. |

| [22] | 张宇文, 毋万来, 赵保平, 等. 新型果树疏花疏果双口剪和双体剪[J]. 落叶果树, 2020, 52(2): 68. |

| ZHANG Yuwen, WU Wanlai, ZHAO Baoping, et al. Two -mouth shears and two - body shears for thinning flower and fruit in fruit trees[J]. Deciduous Fruits, 2020, 52(2): 68. | |

| [23] | 全朋坤, 李艳聪, 张帅杰, 等. 苹果成熟季树枝力学特性研究[J]. 中国农机化学报, 2016, 10(10): 44-47. |

| QUAN Pengkun, LI Yancong, ZHANG Shuanijie, et al. Research Advances in flower and fruit management for apple tree study on mechanical properties of apple ripened tree branch[J]. Journal of Chinese Agricultural Mechanization, 2016, 10(10): 44-47 | |

| [24] | 周艳, 潘云飞, 何磊. 牵引式疏花机设计与试验[J]. 中国农机化学报, 2022, 43(11):43-49 |

| ZHOU Yan, PAN Yunfei, HE Lei, et al. Design and experiment of Tractor flower-thinning machine[J]. Chinese Journal of Agricultural Mechanization, 2022, 43(11):43-49 | |

| [25] | 袁常伟. 桃树疏花机的设计与性能试验[D]. 保定: 河北农业大学, 2021. |

| YUAN Changwei. Design and performance test of peach flower thinning machine[D]. Baoding: Agricultural University of Hebei, 2021. |

| No related articles found! |

| Viewed | ||||||||||||||||||||||||||||||||||||||||||||||||||

|

Full text 53

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Abstract 107

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||