新疆农业科学 ›› 2023, Vol. 60 ›› Issue (10): 2566-2573.DOI: 10.6048/j.issn.1001-4330.2023.10.027

谭新赞1( ), 沈从举1(

), 沈从举1( ), 代亚猛1, 李帆1, 贾首星1, 蒙贺伟2

), 代亚猛1, 李帆1, 贾首星1, 蒙贺伟2

收稿日期:2023-02-03

出版日期:2023-10-20

发布日期:2023-11-01

通信作者:

沈从举(1982-),河北衡水人,副研究员,硕士生导师,研究方向为农业机械,(E-mail)作者简介:谭新赞(1987-),四川绵阳人,助理研究员,研究方向为农业机械,(E-mail)343847644@qq.com

基金资助:

TAN Xinzan1( ), SHEN Congju1(

), SHEN Congju1( ), DAI Yameng1, LI FAN1, JIA Shouxing1, MENG Hewei2

), DAI Yameng1, LI FAN1, JIA Shouxing1, MENG Hewei2

Received:2023-02-03

Online:2023-10-20

Published:2023-11-01

Correspondence author:

SHEN Congju (1982-), born in Hengshui, Hebei Province, associate professor, master supervisor, research direction: Agricultural machinery design and experimental research, (E-mail) Supported by:摘要:

【目的】 基于自激振动深松减阻原理,研制1SZL-300型振动深松整地联合作业机。【方法】 利用Solidworks和CAXA绘图软件设计整机及关键部件结构,研究振动深松部件单体和激振弹簧选型,分析深松铲入土受力及自激振动减阻原理。【结果】 弹簧自激振动能够有效减小牵引阻力,自激振动条件下样机深松深度(耕深)382 mm,深松耕深稳定性系数96.8%,土壤膨松度为28.6%,土壤扰动系数为67.5%,地

中图分类号:

谭新赞, 沈从举, 代亚猛, 李帆, 贾首星, 蒙贺伟. 1SZL-300型振动深松整地联合作业机的研制[J]. 新疆农业科学, 2023, 60(10): 2566-2573.

TAN Xinzan, SHEN Congju, DAI Yameng, LI FAN, JIA Shouxing, MENG Hewei. Development of 1SZL-300 type vibratory subsoiling and soil preparation combined machine[J]. Xinjiang Agricultural Sciences, 2023, 60(10): 2566-2573.

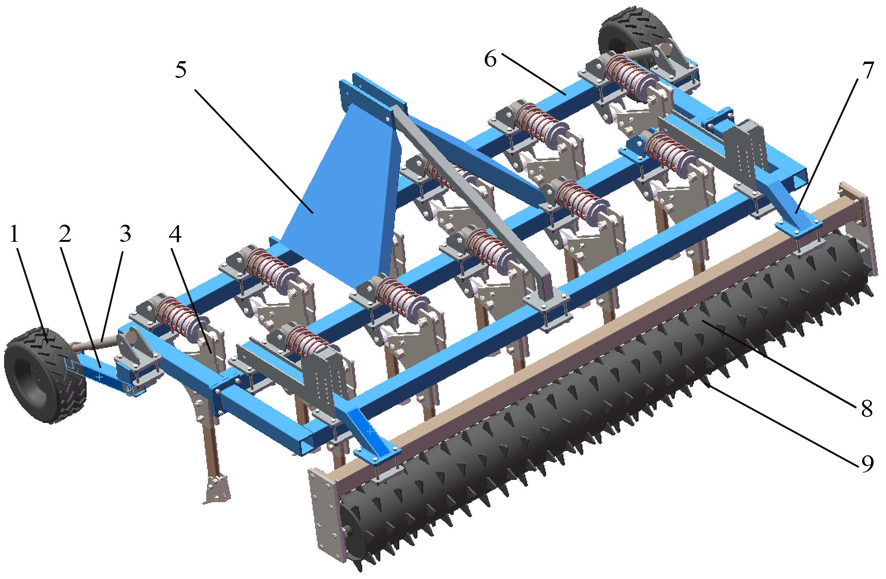

图1 1SZL-300型振动深松整地联合作业机结构 注:1.行走轮;2.行走轮架;3.液压机构;4.深松部件;5.牵引架;6.机架;7.支架;8.碎土辊;9.碎土齿

Fig.1 Structural diagram of 1SZL-300 type vibratory subsoiling and soil preparation combined machine Note:1.Road wheel,2.Walking wheel frame,3.Hydraulic mechanism, 4.Deep loose parts, 5.Traction frame, 6.The machine frame, 7.Support, 8.Earth crushing roller,9.Broken tooth

| 项目 Item | 设计值 Design value |

|---|---|

| 结构型式 Structure type | 悬挂式 |

| 振动方式 Vibrating mode | 自激振动 |

| 配套动力 Matching power/kW | ≥88.6 |

| 整体尺寸(长×宽×高) Overall size (length× width×height)(mm) | 2 200 ×3 300 ×1 600 |

| 工作幅宽 Working width(mm) | 3 000 |

| 深松铲结构形式 Structural form of deep subsoiling shovel | 凿铲式 |

| 深松铲排列方式 Arrangement of subsoilers | 两行交错 |

| 深松铲数量/组 Number of subsoilers/group | 可选(11、9、7) |

| 深松铲间距 Distance between deep loosening shovels(mm) | 可调(240 ~ 460) |

| 作业速度 Operating speed (km/h) | 3 ~ 8 |

| 深松深度 Subsoiling depth (mm) | 250 ~ 450 |

| 整地结构型式 Ground structure type | 钉齿式碎土辊 |

| 碎土辊横向碎土宽度 Horizontal width of broken soil roller(mm) | 3000 |

| 作业效率 Operating efficiency (hm2/h) | 1.5 ~ 2.5 |

表1 整机主要结构及性能参数

Tab.1 Main structure and performance parameters of the machine

| 项目 Item | 设计值 Design value |

|---|---|

| 结构型式 Structure type | 悬挂式 |

| 振动方式 Vibrating mode | 自激振动 |

| 配套动力 Matching power/kW | ≥88.6 |

| 整体尺寸(长×宽×高) Overall size (length× width×height)(mm) | 2 200 ×3 300 ×1 600 |

| 工作幅宽 Working width(mm) | 3 000 |

| 深松铲结构形式 Structural form of deep subsoiling shovel | 凿铲式 |

| 深松铲排列方式 Arrangement of subsoilers | 两行交错 |

| 深松铲数量/组 Number of subsoilers/group | 可选(11、9、7) |

| 深松铲间距 Distance between deep loosening shovels(mm) | 可调(240 ~ 460) |

| 作业速度 Operating speed (km/h) | 3 ~ 8 |

| 深松深度 Subsoiling depth (mm) | 250 ~ 450 |

| 整地结构型式 Ground structure type | 钉齿式碎土辊 |

| 碎土辊横向碎土宽度 Horizontal width of broken soil roller(mm) | 3000 |

| 作业效率 Operating efficiency (hm2/h) | 1.5 ~ 2.5 |

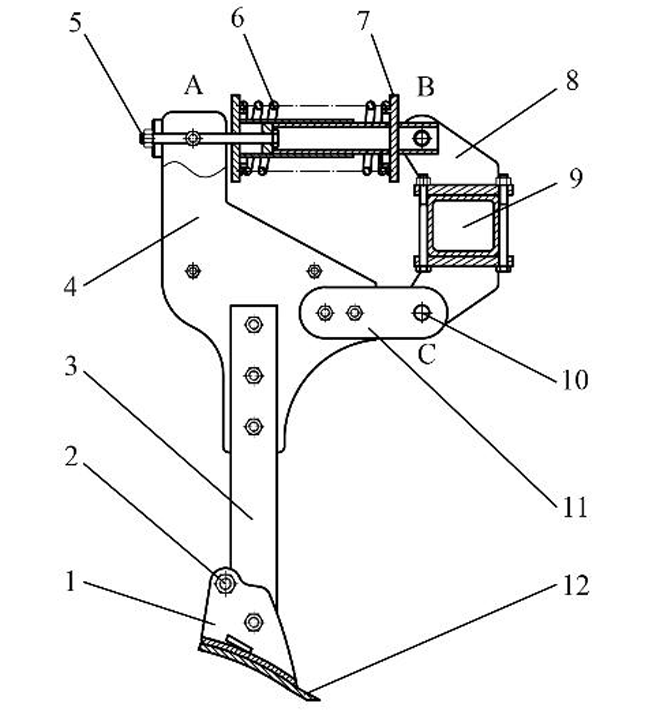

图3 深松部件单体结构 注:1.铲托;2.安全螺栓;3.铲柄;4.固定板;5.调整螺栓;6.弹簧;7.弹簧架;8.连接座;9.机架;10.销轴;11.连接板;12.铲头

Fig.3 Single structure of subsoiling parts Note: 1.Shovel support; 2.Safety bolt; 3.The shovel handle; 4.Fixed plate; 5.Adjust bolts; 6.The spring; 7.Spring frame; 8.Connecting seat; 9.The machine frame; 10.The pin shaft; 11.Connecting plate; 12.The shovel head

| 参数Parameter | 数值 Numerical value |

|---|---|

| 结构总高 Total height of structure(mm) | 1 100 |

| 铲柄高度 Height of shovel handle(mm) | 500 |

| 铲柄位置调节间距尺寸 Spacing size of shovel handle position adjustment(mm) | 100 |

| 凿形铲入土角 Chisel shovel into soil angle(°) | 30 |

| 深松深度 Subsoiling depth(mm) | 250 ~ 450 |

| 铲头刃角 Blade angle of shovel head(°) | 18 |

| 铲头曲率半径 Curvature radius of shovel head(mm) | 320 |

| 铲头长度 Shovel head length(mm) | 145 |

表2 深松部件单体主要结构设计参数

Tab.2 The parameter of subsoiler structure

| 参数Parameter | 数值 Numerical value |

|---|---|

| 结构总高 Total height of structure(mm) | 1 100 |

| 铲柄高度 Height of shovel handle(mm) | 500 |

| 铲柄位置调节间距尺寸 Spacing size of shovel handle position adjustment(mm) | 100 |

| 凿形铲入土角 Chisel shovel into soil angle(°) | 30 |

| 深松深度 Subsoiling depth(mm) | 250 ~ 450 |

| 铲头刃角 Blade angle of shovel head(°) | 18 |

| 铲头曲率半径 Curvature radius of shovel head(mm) | 320 |

| 铲头长度 Shovel head length(mm) | 145 |

| 编号 Number | 弹簧直径 Spring diameter d (mm) | 弹簧中径 Mean diameter of coil D(mm) | 自由高度 Unsupported heighth (mm) | 弹簧刚度 Spring stiffness K(N/mm) |

|---|---|---|---|---|

| I | 18 | 85 | 240 | 260 |

| Ⅱ | 20 | 80 | 240 | 475 |

表3 选取的激振弹簧主要参数

Tab.3 Main parameters of self-excited vibration spring

| 编号 Number | 弹簧直径 Spring diameter d (mm) | 弹簧中径 Mean diameter of coil D(mm) | 自由高度 Unsupported heighth (mm) | 弹簧刚度 Spring stiffness K(N/mm) |

|---|---|---|---|---|

| I | 18 | 85 | 240 | 260 |

| Ⅱ | 20 | 80 | 240 | 475 |

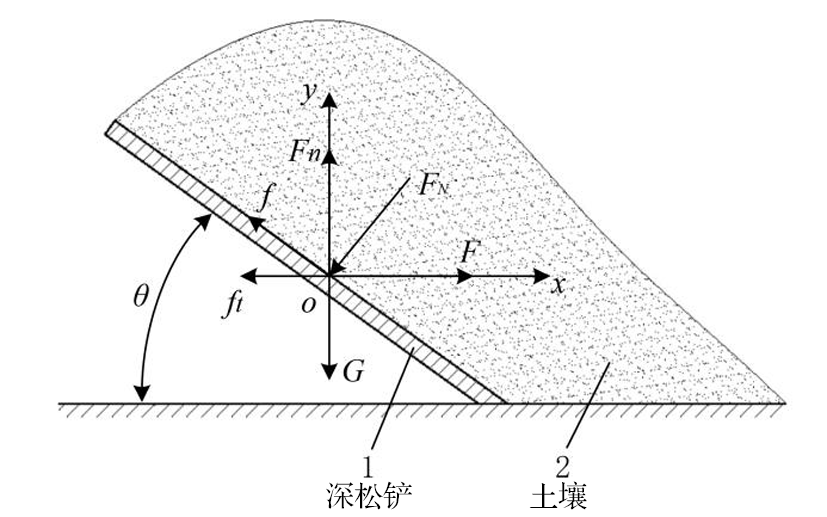

图5 深松铲受力示意 注:F为牵引力,FN为铲上土壤对深松铲的压力,Fn为铲下土壤对深松铲的支撑力,ft为深松铲的土壤阻力,f为土壤对深松铲的摩擦阻力,G为深松铲及铲上土壤的重力,θ为深松铲的入土角

Fig.5 Stress diagram of subsoiling shovel Note:F is the traction force,FN is the pressure of the soil on the shovel on the deep loosening shovel,Fn is the support force of the soil under the shovel on the deep Loosening shovel,ft is the soil resistance of the deep loosening shovel,f is the frictional resi stance of the soil to the deep loosening shovel,G is the gravity of the deep loosening shovel and the soil on the shovel,θ is the entry angle of the deep loosening shovel

| 检验项目 Inspection item | 评定指标 Deliberated index | 检验结果 Results |

|---|---|---|

| 深松深度(耕深) Depth of subsoiling(mm) | ≥250 | 382 |

| 深松耕深稳定性系数 Stability coefficient of depth of subsoiling(%) | ≥80 | 96.8 |

| 土壤膨松度 Soil bulk density(%) | 10 ~ 40 | 28.6 |

| 土壤扰动系数 Soil disturbance coefficient(%) | ≥50 | 67.5 |

| (地表10cm内)碎土率 Soil fragmentation rate (within 10cm of the surface)(%) | ≥60 | 62.8 |

| 纯工作小时生产率 Pure work-hour productivity / hm2/h | - | 2.2 |

表4 样机主要作业性能指标检测

Tab.4 Test results of the main operating performance indexes of the prototype

| 检验项目 Inspection item | 评定指标 Deliberated index | 检验结果 Results |

|---|---|---|

| 深松深度(耕深) Depth of subsoiling(mm) | ≥250 | 382 |

| 深松耕深稳定性系数 Stability coefficient of depth of subsoiling(%) | ≥80 | 96.8 |

| 土壤膨松度 Soil bulk density(%) | 10 ~ 40 | 28.6 |

| 土壤扰动系数 Soil disturbance coefficient(%) | ≥50 | 67.5 |

| (地表10cm内)碎土率 Soil fragmentation rate (within 10cm of the surface)(%) | ≥60 | 62.8 |

| 纯工作小时生产率 Pure work-hour productivity / hm2/h | - | 2.2 |

| [18] | Geal W R, Van der Berch. Tillage and traction of the soil dynamics[M]. Beijing: China Agricultural Machinery Press, 1981. |

| [1] | Ahmad N, Fayyaz-UI-Hassan, Qadir G. Effect of subsurface soil compaction and improvement measures on soil properties[J]. International Journal of Agriculture and Biology, 2007, 9(3):509-513. |

| [2] | 郑洪兵, 郑金玉, 罗洋, 等. 长期不同耕作方式下的土壤硬度变化特征[J]. 农业工程学报, 2015, 31(9):63-70. |

| ZHENG Hongbing, ZHENG Jinyu, LUO Yang, et al. Change characteristic of soil compaction of long-term different tillage methods in cropland[J]. Transactions of the Chinese Society of Agricultural Engineering, 2015, 31(9):63-70. | |

| [3] | 王鸿斌, 陈丽梅, 赵兰坡, 等. 吉林玉米带现行耕作制度对黑土肥力退化的影响[J]. 农业工程学报, 2009, 25(9):301-305. |

| WANG Hongbin, CHEN Limei, ZHAO Lanpo, et al. Influence of present farming system of corn belt on fertility degradation in Jilin Province[J]. Transactions of the Chinese Society of Agricultural Engineering, 2009, 25(9):301-305. | |

| [4] | Ingrid G.Martínez, Christian Prat, Carlos Ovalle, et al. Subsoiling improves conservation tillage in cereal production of severely degraded Alfisols under Mediterranean climate[J]. Geoderma, 2012,(189/190):10-17. |

| [5] | 李磊, 张荣英, 陈海燕. 仿生深松铲发展现状与展望[J]. 农机化研究, 2015, 37(2):265-268. |

| LI Lei, ZHANG Rongying, CHEN Haiyan, et al. The Development of Bionic Subsoilers and Outlooks[J]. Journal of Agricultural Mechanization Research, 2015, 37(2):265-268. | |

| [6] | 张祥彩, 李洪文, 何进, 等. 耕作方式对华北一年两熟区土壤及作物特性的影响[J]. 农业机械学报, 2013, 44(S1):77-82,71. |

| ZHANG Xiangcai, LI Hongwen, HE Jin, et al. Effects of Different Tillage Managements on Characteristics of Soil and Crop in Annual Double Cropping Areas in Northern China[J]. Transactions of the Chinese Society for Agricultural Machinery, 2013, 44(S1):77-82,71. | |

| [7] | 沈从举, 贾首星, 潘俊兵. 1SZL-420型自激振动深松机的设计与试验[J]. 甘肃农业大学学报, 2017, 52(4):171-177. |

| SHEN Congju, JIA Shouxing, PAN Junbing, et al. Design and experiment of 1SZL-420 self - exciting vibration subsoiler[J]. Journal of Gansu Agricultural University, 2017, 52(4):171-177. | |

| [8] | 张思远. 受迫振动深松机的设计与研究[D]. 石河子: 石河子大学, 2018. |

| ZHANG Siyuan. Design and Experimental study on the Forced Vibration Subsoiler[D]. Shihezi: Shihezi University, 2018. | |

| [9] | 徐宗保, 董欣, 李紫辉, 等. 振动式深松中耕作业机的研制与试验研究[J]. 农机化研究, 2010, 32(1):182-184. |

| XU Zongbao, DONG Xin, LI Zihui, et al. Development and Experimental Study of the Machine of Vibrating Deeploose and Intertillage[J]. Journal of Agricultural Mechanization Research, 2010, 32(1):182-184. | |

| [10] | 张思远, 王维新, 李霞, 等. 受迫振动深松机减阻效果试验研究[J]. 现代制造工程, 2018,(8):1-4,74. |

| ZHANG Siyuan, WANG Weixin, LI Xia, et al. Experimental study on drag reduction efficiency of forced-vibration subsoiler[J]. Modern Manufacturing Engineering, 2018,(8):1-4,74. | |

| [11] | 李明军, 于家川, 王仁兵, 等. 液压强迫式振动深松单体作业参数优化与试验[J]. 农机化研究, 2022, 44 (10):97-107. |

| LI Mingjun, YU Jiachuan, WANG Renbing, et al. Operation Parameter Optimization and Experiment of Hydraulic Forced Vibration Subsoiling Monomer[J]. Journal of Agricultural Mechanization Research, 2022, 44 (10):97-107. | |

| [12] | 张斌, 沈从举, 李承明, 等. 自激振动深松机关键部件仿真设计及试验[J]. 农机化研究, 2021, 43(10):51-57,63. |

| ZHANG Bin, SHEN Congju, LI Chengming, et al. Simulation Design and Test of Key Components of Self-excited Vibration Subsoiler[J]. Journal of Agricultural Mechanization Research, 2021, 43(10):51-57,63. | |

| [13] | 王云霞, 张东兴, 杨丽, 等. 液压激振源自激振动深松机深松单体设计与试验[J]. 农业工程学报, 2018, 34(11):40-48. |

| WANG Yunxia, ZHANG Dongxi, YANG Li, et al. Design and experiment of hydraulically self-excited vibration subsoiler[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(11):40-48. | |

| [14] | 屈通, 李霞, 汤明军. 自激振动深松对土壤物理特性的影响[J]. 农机化研究, 2018, 40(12):179-183. |

| QU Tong, LI Xia, TANG Mingjun, et al. Effects of the Excited - vibration Subsoiler on Soil Properties[J]. Journal of Agricultural Mechanization Research, 2018, 40(12):179-183. | |

| [15] | 汤明军. 自激振动深松机关键部件的设计与试验研究[D]. 石河子: 石河子大学, 2017. |

| TANG Mingjun. Design and Experimental study on the Self-Excited Vibration Subsoiler and Key Parts[D]. Shihezi: Shihezi University, 2017. | |

| [16] |

Sakai K., Terao H., Nambu S. The dynamic behaviour of a tractor-vibrating subsoiler system and the effect of the virtual hitch point[J]. Journal of Terramechanics, 1989, 25(4), 241-247.

DOI URL |

| [17] | JB/T 10295-2014.深松整地联合作业机[S]. |

| JB/T 10295-2014. Combined implement for subsoiler and cultivating[S]. | |

| [18] | W.R.吉尔,G.E.范德伯奇. 耕作和牵引土壤动力学[M]. 北京: 中国农业机械出版社,1981. |

| [1] | 韩冬荟;潘学标. 解析气温变化和物化投入对阿克苏地区棉花产量的影响[J]. , 2013, 50(10): 1946-1953. |

| [2] | 布娲鹣·阿布拉;陈俭;肖霞;方媛;买买提江·热夏提. 中国与中亚国家的农业机械产品贸易研究[J]. , 2012, 49(2): 384-389. |

| [3] | 李慕春;张静;古丽克孜·阿日甫;阿依古丽·塔西. 辣椒碱与茶皂素对棉蚜的毒力测定及田间药效试验[J]. , 2010, 47(6): 1132-1136. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||